High quality cheap price stone clay coal pulverizer mini crusher for sale

Product Description

Hammer crusher can crush the material with a maximum particle size of 600-1800 mm to 20 or 20 mm or less,Hammer crusher is suitable for cement, chemicals, power, metallurgy and other industrial sectors to crush medium hardness materials such as limestone, slag, coke, coal and other materials.

Technical parameters

|

Model |

Input Size |

Output Size |

Capacity |

Power |

Weight |

Dimensions |

|

PC400*400 |

≤100mm |

≤10mm |

5-8t |

7.5kw |

0.9t |

844*942*878mm |

|

PC600*400 |

≤100mm |

≤15mm |

10-12t |

18.5kw |

1.03t |

1054*972*1117mm |

|

PC600*600 |

≤100mm |

≤15mm |

12-18t |

45kw |

2.14t |

1315*840*1014mm |

|

PC800*600 |

≤120mm |

≤15mm |

20-25t |

55kw |

2.45t |

1515*2886*1040mm |

|

PC800*800 |

≤120mm |

≤15mm |

35-45t |

75kw |

3.05t |

1515*2831*1040mm |

|

PC1000*800 |

≤200mm |

≤15mm |

25-40t |

90kw |

6.5t |

3206*2210*1515mm |

|

PC1000*1000 |

≤200mm |

≤15mm |

40-80t |

110kw |

7.59t |

3514*2230*1515mm |

|

PC1200*1000 |

≤200mm |

≤15mm |

45-110t |

132kw |

11.7t |

2630*1780*2050mm |

Introduction of roll crusher

Roll crusher is suitable for crushing medium hardness materials in cement, chemical industry, electric power, metallurgy, building materials, refractory materials and other industrial sectors, such as limestone, slag, coke, coal and other materials in crushing, fine crushing operations. This series of roller crusher is mainly composed of roller wheel, roller wheel supporting bearing, pressing and adjusting device and driving device.

Working principle of roll crusher

Roll crusher is the use of a pair of round rotating roller crushing materials. The material falls into the gap between the two rollers through the upper feeding mouth of the equipment, and is gradually crushed by the action of friction between the two rollers, and the finished material leaks out from the bottom. When there is too hard to be broken material, the roller automatically gives way, so that the gap between the rollers increases, the material falls down, with the action of hydraulic cylinder or spring, the roller restores to the original gap, so as to protect the machine, adjust the gap between the two rollers, you can control the maximum particle size of the product.

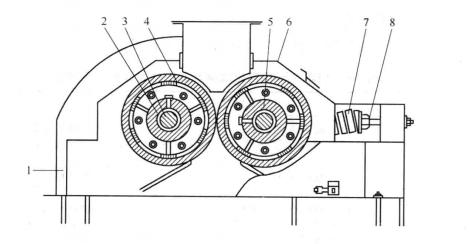

Roller crusher construction

The figure shows a double roll crusher. It consists of crushing roller, adjusting device, spring safety device, transmission device and frame, etc.

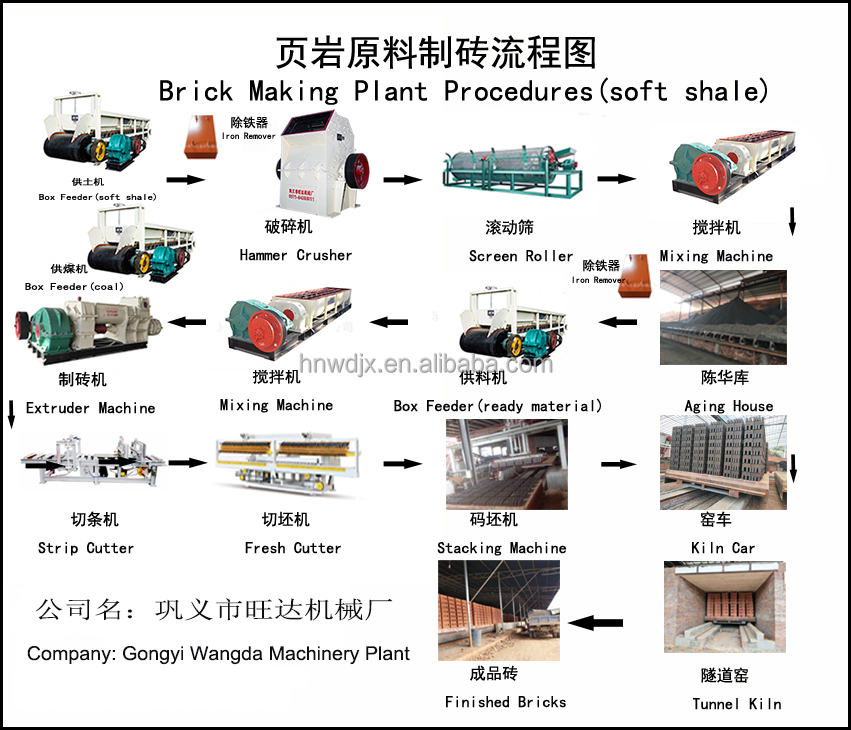

Production flow