High Quality for Automatic Small Soil Brick Making Machine - JKB5045 Automatic Vacuum Brick Extruder – Wangda

High Quality for Automatic Small Soil Brick Making Machine - JKB5045 Automatic Vacuum Brick Extruder – Wangda Detail:

About JKB50/45 Automatic Clay Brick Making Machine:

Jkb50/45-3.0 automatic clay brick machine is suitable for all shapes and sizes of solid brick, hollow brick, porous brick and other clay products. Also suitable for a variety of raw materials. It is characterized by novel structure, advanced technology, high extrusion pressure, high output and high vacuum. Pneumatic clutch control, sensitive, convenient and reliable.

Main technical parameters of JKB50/45 Automatic Clay Brick Making Machine:

| No. | Item | Units of measurement | JKB50/45 Vacuum Extruder Automatic Clay Brick Machine |

| 1 | Productin capacity | standard brick/hour | 12000-16000 |

| 2 | Extrusion pressure | Mpa | 3.0 |

| 3 | Vacuum degree | Mpa | ≥0.092 |

| 4 | Power | kW | 160 |

| 5 | Moisture content | % | 14-18% |

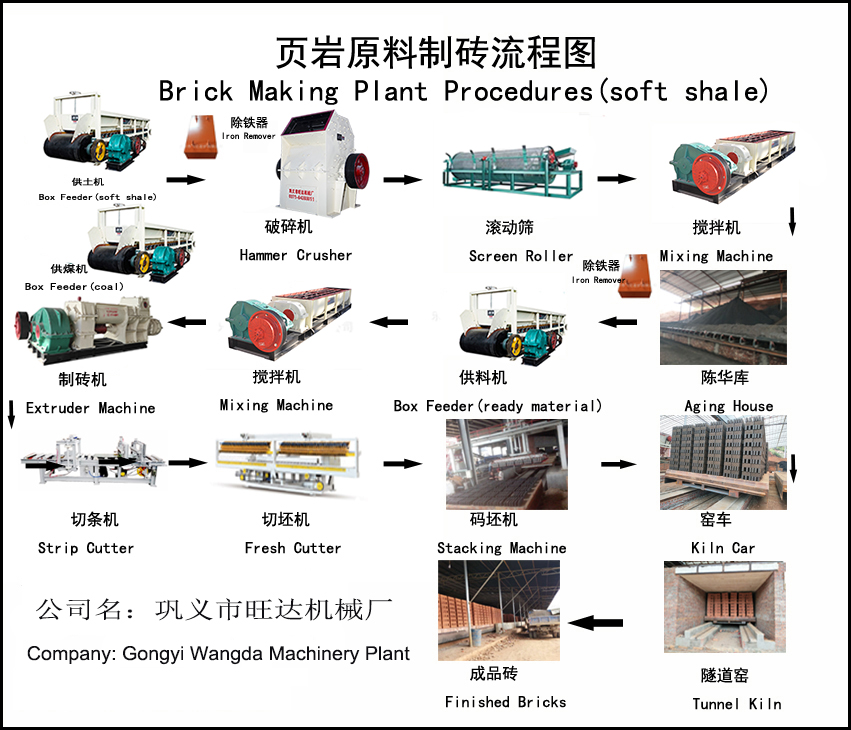

Full Brick Production Line with JKB50/45 Automatic Clay Brick Making Machine:

Brick Making Auxiliary machine:

1. Box feeder for Automatic Clay Brick Making Machine:

Box Feeder is the feeding equipment which is used to balance and ration during brick producing. It is applicable to various brick materials with controllable feeding speed and feeding quantity. It is the first part of clay brick making machine.

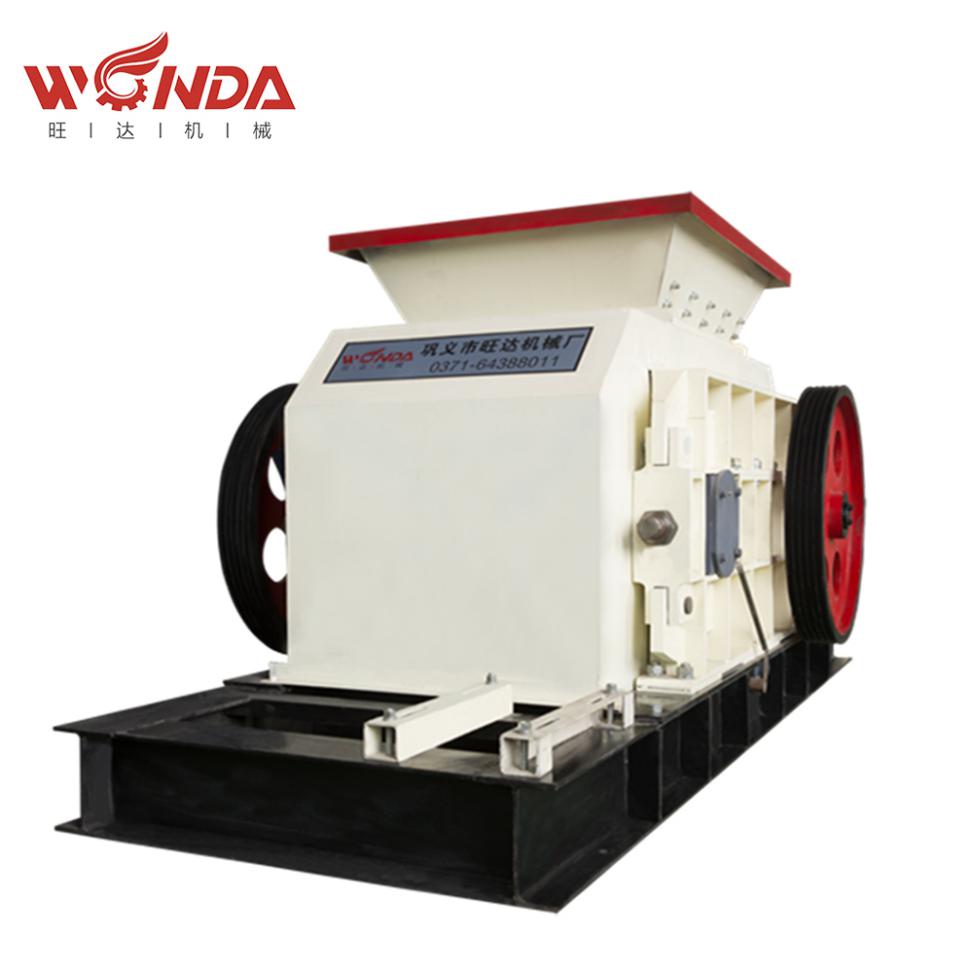

2. Roller crusher for Automatic Clay Brick Making Machine:

Crusher and wear on the roller machine is also a raw material crushing, squeezing, grinding equipment. The advantages of the device is low power, reasonable price, suitable for crushing clay raw materials. It is the second step of clay brick making machine.

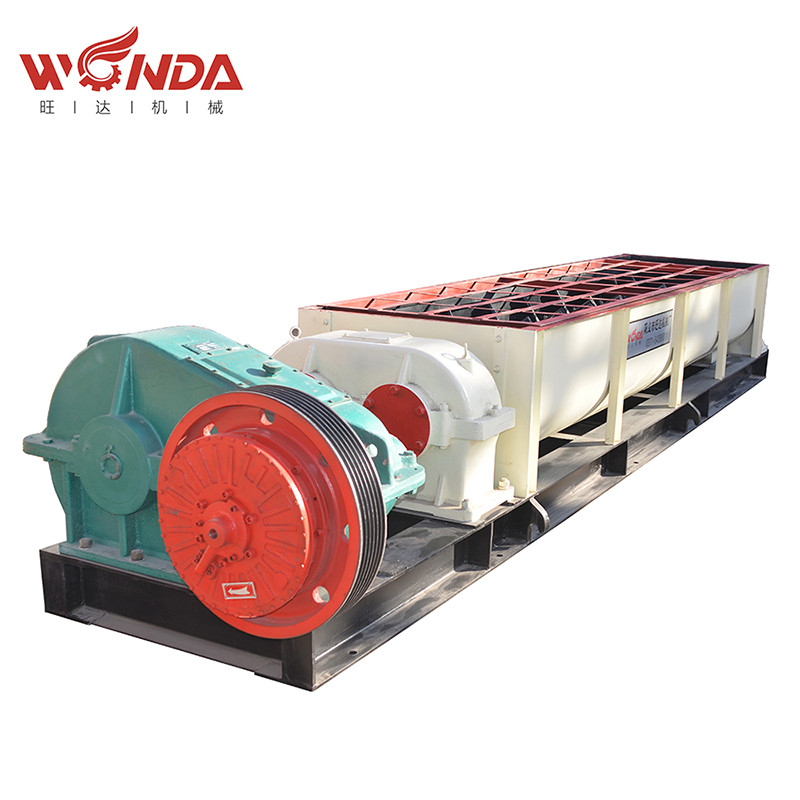

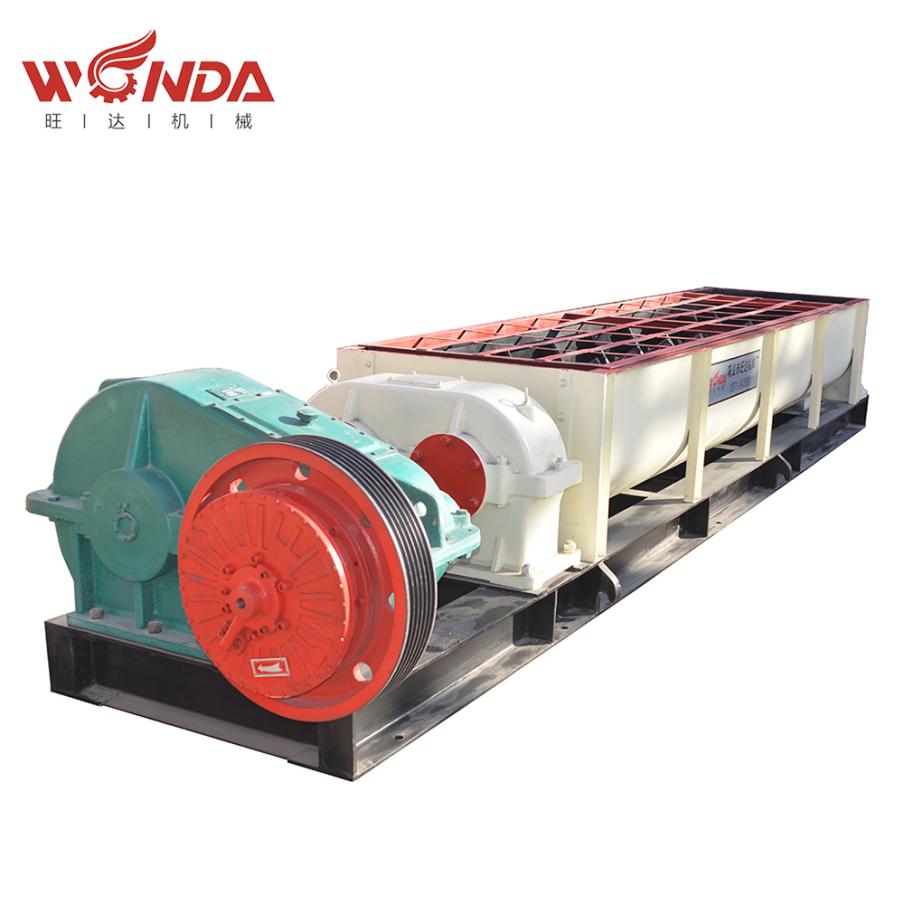

3. Double-shaft mixer for Automatic Clay Brick Making Machine:

Double-Shaft Mixer is used to mix water with crushed raw materials, increase the comprehensive quality of raw materials, greatly improve appearance quality and ratio of forming, thus it is indispensable raw material processing machine for red clay brick making.

4. Strip cutting and adobe brick cutting machine of Automatic Clay Brick Making Machine.

Strip cutting and adobe brick cutting machine is mainly used to cut mud which is squeezed from extruder into qualified red clay brick during sintering brick production. It has advanage of high accuracy, easy operation, and simple maintenance an so on.

Certifications

Advantages

We are a high-tech enterprise, integrating science, industry and trade for brick and tile machinery with our brand more than 30 varieties and over 100 specifications. Now we have built more than 2000 brick production line in China and abroad.

1. You need soil brick machine clay brick machine, interlocking brick machine or concrete block machine?

2. Your brick size( length, width and height)

3.Your brick picture and brick production

We are professional clay brick machine , concrete block making machine, and interlock brick machine manufacturer, if you are interested, please come here.

Product detail pictures:

Related Product Guide:

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for High Quality for Automatic Small Soil Brick Making Machine - JKB5045 Automatic Vacuum Brick Extruder – Wangda , The product will supply to all over the world, such as: Croatia, Cambodia, French, We are looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products' quality, you can return within 7days with their original states.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.