High Efficiency Energy Saving Automatic Tunnel Kiln

Product Description

Our company has tunnel kiln brick factory construction experience at home and abroad. The basic situation of the brick factory is as follows:

1. Raw materials: soft shale + coal gangue

2. Kiln body size :110mx23mx3.2m, inner width 3.6m; Two fire kilns and one dry kiln.

3. Daily capacity: 250,000-300,000 pieces/day (Chinese standard brick size 240x115x53mm)

4. Fuel for local factories: coal

5. Stacking method: by Automatic Brick Stacking Machine

6. Production line machinery: Box feeder; Hammer crusher machine; Mixer; Extruder; Brick cutting machine; Brick stacking machine; Kiln car; Ferry car, Fan; Pushing car, etc

7- Site project photos

Structure

Tunnel kiln can be divided into pre - heating zone, firing zone, cooling zone.

1. The preheating zone accounts for 30-45% of the total length of kiln, temperature range is from room temperature to 900℃; The green body of the vehicle is gradually heated by contacting the flue gas generated by the combustion of the fuel from the burning zone to complete the preheating process of the green body.

2. The firing zone accounts for 10-33% of the total length of the kiln, the temperature range is from 900℃ to the highest temperature; With the help of the heat released by fuel combustion, the body achieves the highest firing temperature required to complete the firing process of the body.

3.The cooling zone accounts for 38-46% of the total length of the kiln, and the temperature range is from the highest temperature to the temperature of the product out of the kiln; The products fired at high temperature enter the cooling belt and exchange heat with a large amount of cold air from the end of the kiln to complete the cooling process of the body.

Advantages

Tunnel kiln has a series of advantages compared with old kiln.

1. Continuous production, short cycle, large output, high quality.

2. The use of countercurrent principle of work, so the heat utilization rate is high, fuel economy, because the use of heat retention and waste heat are very good, so the fuel is very saving, compared with inverted flame kiln can save about 50-60% of the fuel.

3. The firing time is shorter. It takes 3-5 days from loading to empting for ordinary large kilns, while tunnel kilns can be completed in about 20 hours.

4. labor saving. Not only the operation is simple when firing, but also the operation of loading and discharging kiln is carried out outside the kiln, which is very convenient, improves the working conditions of operators and reduces the labor intensity.

5. Improve quality. The temperature of the preheating zone, the firing zone and the cooling zone is often kept within a certain range, so it is easy to master the firing rule, so the quality is better and the damage rate is less.

6. Kiln and kiln tools are durable. Because the kiln is not affected by rapid cooling and heat, the kiln body has a long service life, usually 5-7 years to repair once.

Successul projects

NO.1- Project in Jian, production capacity 300000-350000pcs/day ; (brick size :240x115x50mm)

NO.2- Project in Fuliang, production capacity : 250000-350000pcs/day.(brick size :240x115x50mm)

NO.3- Project in Muse, Myanamr. production capacity : 100000-150000pcs/day.(brick size :240x115x50mm)

NO.4- Project in Yongshan, production capacity 300000-350000pcs/day ; (brick size :240x115x50mm)

NO.5- Project in Zhagang,production capacity :100000-150000pcs/day;(brick size :240x115x50mm)

NO.6- Project in Sanlong, production capacity: 150000-180000pcs/day;(brick size :240x115x50mm)

NO.7- Project in Lutian, production capacity: 200000-250000pcs/day;(brick size :240x115x50mm)

NO.8- Project in Nepal , production capacity: 100000-150000pcs/day;(235x115x64mm)

NO.9- Project in Mandalay, Myanmar, production capacity: 100000-150000pcs/day;(250x120x64mm)

NO.10- Project in Mozambique, production capacity: 20000-30000pcs/day;(300x200x150mm)

NO.11- Project in Qianshuitan , production capacity: 250000-300000pcs/day;(240x115x50mm)

NO.12- Project in Uzbekistan, production capacity: 100000-150000pcs/day;(250x120x88mm)

Packaging & Shipping

(kiln material: fire bricks, line machinery loading and dispatching)

Our Services

We have a stable and professional overseas project construction team (including: land identification and design; Kiln construction guidance; Machienry installation guide; Production line mechanical test, production guidance, etc.)

Workshop

FAQ

1- Q:which kind of details Customer should know ?

A: Material type: clay, soft shale, coal gangue, fly ash, construction waste soil, etc

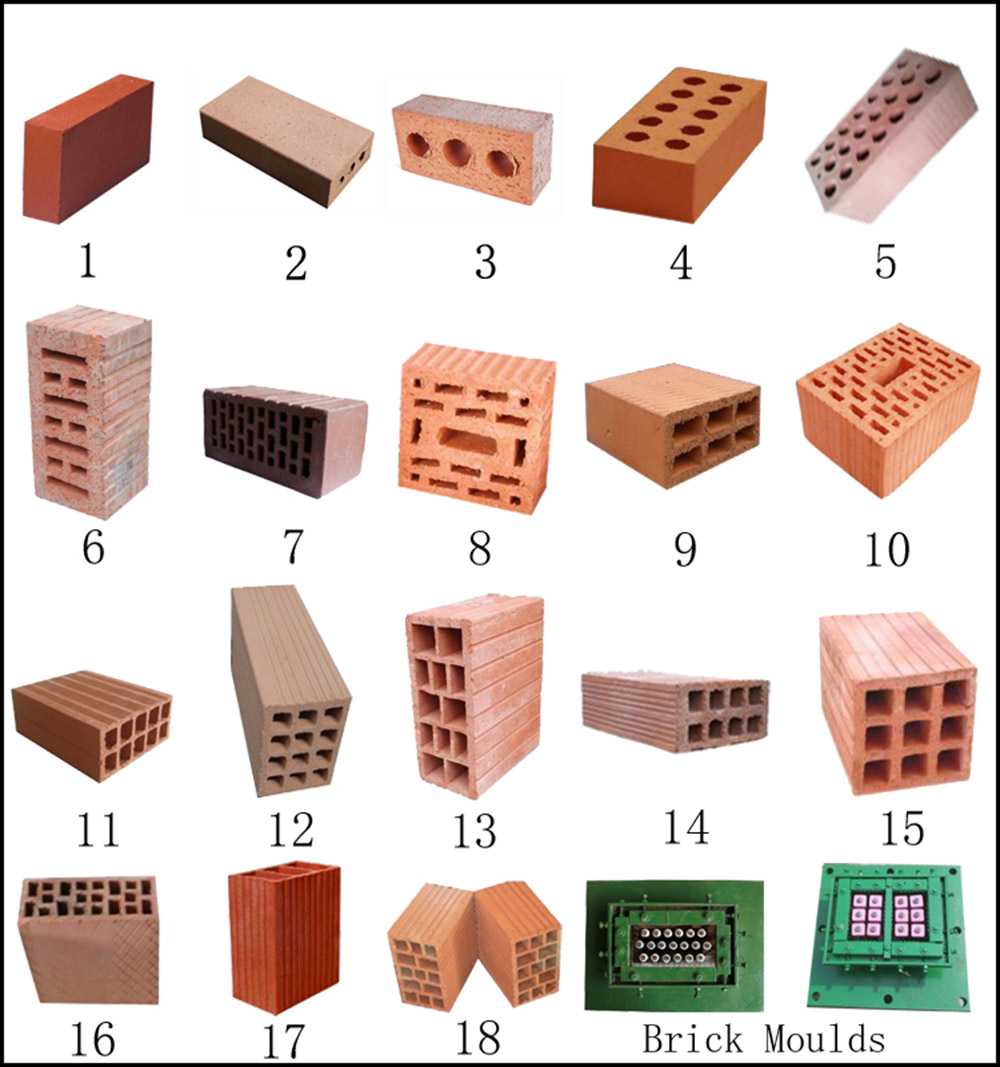

Brick size and shape: The customer needs to know what kind of brick he wants to produce and its size

Daily production capacity: how many finished bricks the customer wants to produce per day.

Stacking method of fresh brick: automatic machine or manual.

Fuel: coal, crushed coal, natural gas, oil or other.

Kiln type: Hofman kiln, Hoffman kiln with a small drying chamber; Tunnel kiln, rotary kiln

Land: How much land does the customer need to prepare?

The details mentioned above are very important, so when the customer wants to build a brick factory, he must know.

2- Q:why choose us:

A: Our company has more than ten years experience in building brick factories abroad. We have a stable overseas service team. Land signage and design; Kiln construction, mechanical installation and test production, free training for local staff, etc.