New Delivery for Brick Making Manufacture - Automatic Pneumatic Brick Stacking Machine – Wangda

New Delivery for Brick Making Manufacture - Automatic Pneumatic Brick Stacking Machine – Wangda Detail:

Product Description

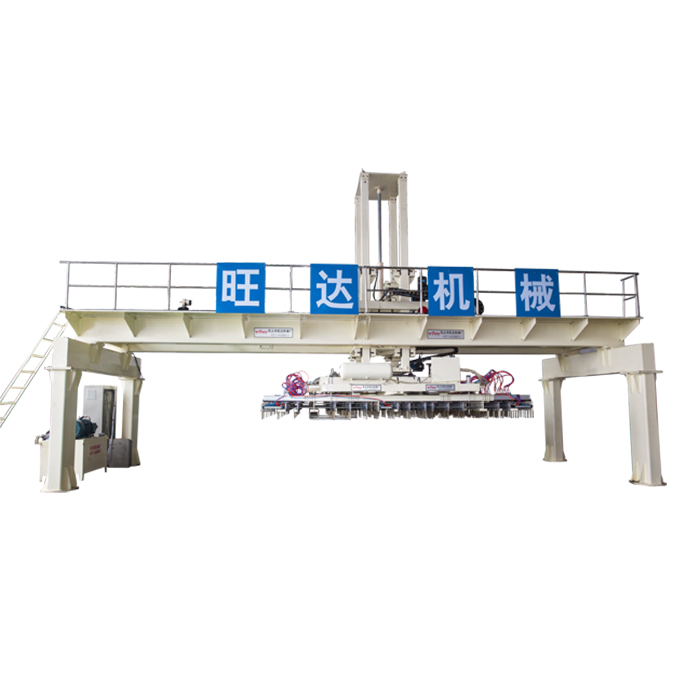

Automatic stacking machine & stacking robot are new brick automatic stacking, replace manual stacking way. It can greatly improve stacking efficiency and reduce labor cost. Depending on the size of the kiln, we should choose different types of stacking machine & stacking robot.

Advantage

1- Fast and efficient energy saving

2- Optimized high performance features make your production more efficient and accurate

3- Super suitable for a variety of brick types

Successful Projects

Product Parameters

| NO. | Type | Daily Production capacity | Main parameters |

| 1 |

3.3m One single fire kiln |

80000-100000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.3m

Kiln length: 132.6m Kiln car size:3.3mx3.42m |

| 2 |

3.6/3.7m One single fire kiln |

10000-150000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.6-3.7m

Kiln length: 141.2m Kiln car size:3.58mx3.84m |

| 3 |

3.6/3.7m One dry one fire kiln |

12000-180000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.6m

Kiln length: 111.6m Kiln car size:3.6mx3.72m |

| 4 |

3.6/3.7m Two dry two fire kilns |

25000-300000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.6m

Kiln length: 111.6m Kiln car size:3.6mx3.72m |

| 5 |

3.9m One single fire kiln |

130000-160000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.9m

Kiln length: 152.4m Kiln car size:3.9mx4.02m |

| … |

… |

… | … |

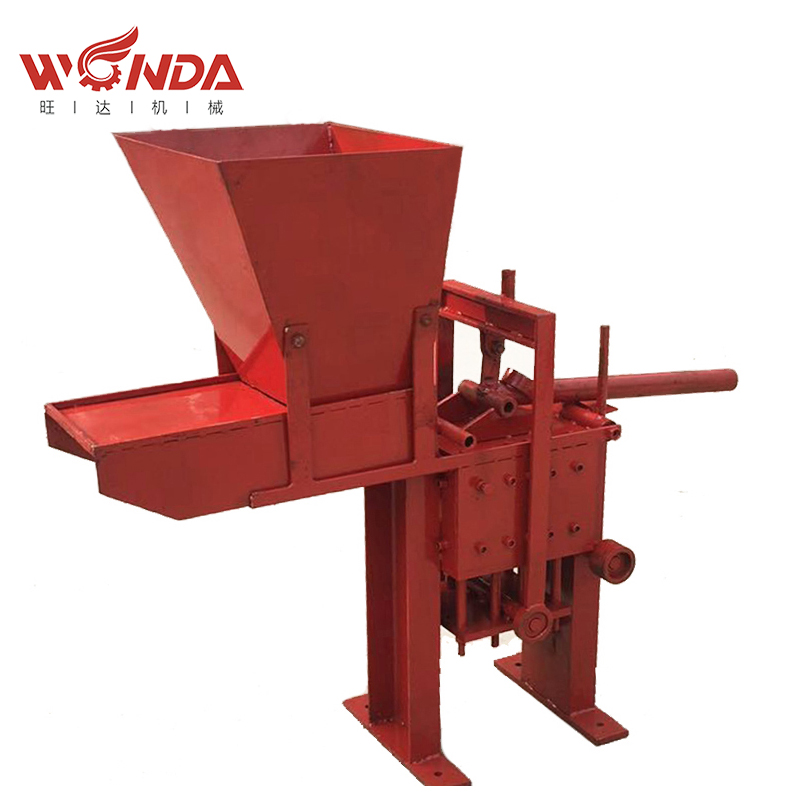

Operation Flow of Brick Setting Machine

The extruded strips are cut into separated brick strips by brick slitter;

The stripes are pushed through the cutting wires to the transitional bed ;

When the transitional bed is fully occupied, the bricks are pushed to the brick board;

The Lift Cylinder controls the chunk clamps down to reach the bricks, then the lift cylinder lifts the clamped bricks to a certain height.

Chunk puts down the bricks on the tunnel kiln car.

The Parts of Automatic Brick-Setting Machine

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for New Delivery for Brick Making Manufacture - Automatic Pneumatic Brick Stacking Machine – Wangda , The product will supply to all over the world, such as: Azerbaijan, Frankfurt, India, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.