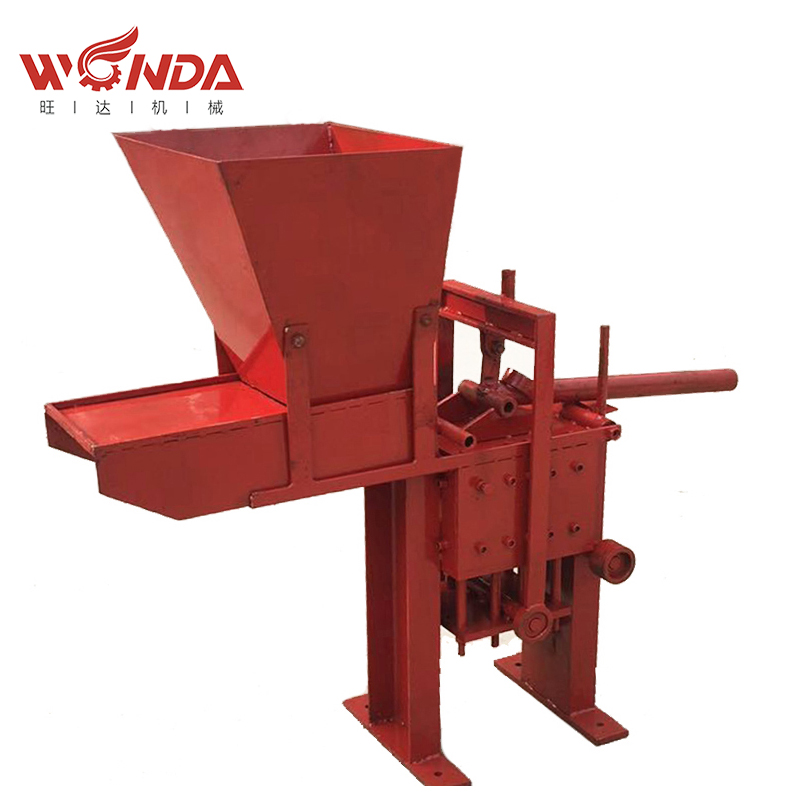

professional factory for Hot Clay Brick Making Machine - WD4-10 Interlocking Brick Making Machine – Wangda

professional factory for Hot Clay Brick Making Machine - WD4-10 Interlocking Brick Making Machine – Wangda Detail:

Introduction

Interlock brick machine is the equipment to produce chain ecological slope protection bricks which protect soil and water by using stone powder, river sand, stone, water, fly ash and cement as raw materials.

Wd4-10 automatic hydraulic interlocking clay brick and concrete brick making machine is suitable for the production of clay brick, clay brick, cement brick and interlocking brick.

1. Fully automatic clay cement brick machine. PLC controller.

2. It is equipped with a belt conveyor and a cement clay mixer.

3. You can make 4 bricks each time.

4. Be deeply praised by domestic and foreign customers.

5. Wd4-10 is an automatic hydraulic brick making machine controlled by PLC, which can be easily operated by a person.

6. Wd4-10 adopts cbT-E316 gear pump driven by motor, double oil cylinders, hydraulic pressure up to 31Mpa, which can ensure high brick density and high brick quality.

7. Moulds can be replaced according to customer requirements.

8.Production capacity. 11,520 bricks per 8 hours(per shift).

WD4-10 can make all of above bricks by changing the moulds, we can also customize the moulds according to your brick size.

Technical Parameters

|

Overall size |

2260x1800x2380mm |

|

Shaping Cycle |

7-10s |

|

Power |

11KW |

|

Electrical |

380v/50HZ (Adjustable) |

|

Hydraulic pressure |

15-22 MPa |

|

Host Machine Weight |

2200KG |

|

Row material |

Soil, clay, sand,cement,water and so on |

|

Capacity |

1800pcs/hour |

|

Type |

Hydraulic press |

|

Pressure |

60 Ton |

|

Needed Workers |

2-3 workers |

Interlock Brick Machine Molds

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for professional factory for Hot Clay Brick Making Machine - WD4-10 Interlocking Brick Making Machine – Wangda , The product will supply to all over the world, such as: Estonia, Afghanistan, Bulgaria, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.