Factory wholesale Brick Making Machinery Automatically - WD1-15 Hydraulic brick pressing machine – Wangda

Factory wholesale Brick Making Machinery Automatically - WD1-15 Hydraulic brick pressing machine – Wangda Detail:

Product Description

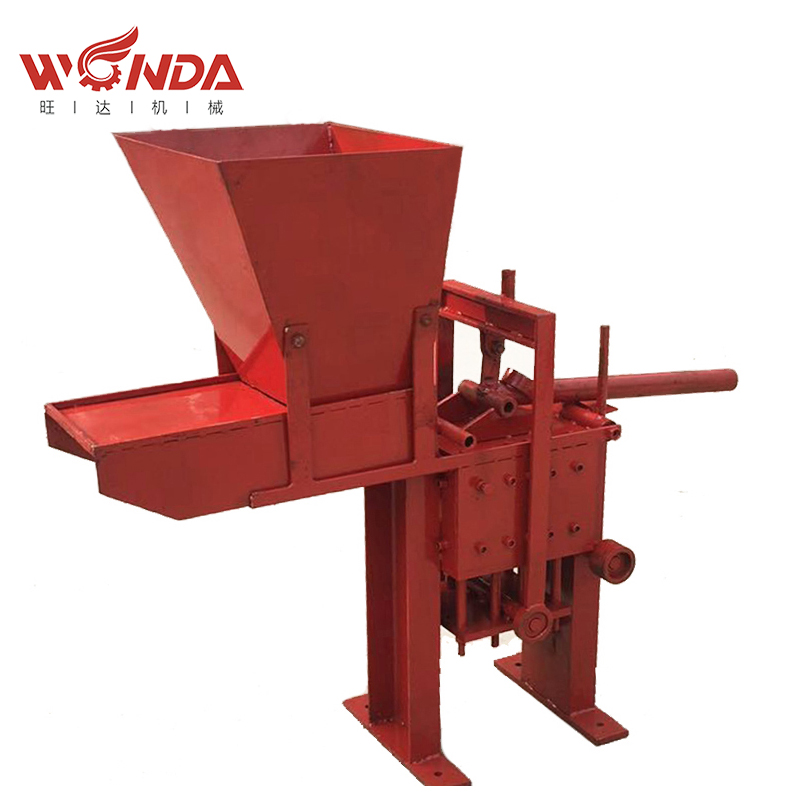

WD1-15 Hydraulic Interlocking Brick Making Machine is our newest clay and cement brick making machine.it is semi-automatic operation machine.its material feeding.mould pressing and mould lifting automatically ,you can chose diesel engine or motor for power supply.

The most versatile of the market, for enable varied models of blocks, bricks and floors in only one equipment, without the need of buy another machine.

Eco Brava interlock brick machine is a professional hydraulic press for the production of construction interlocking blocks. Using cement, sand, clay, shale, fly ash, lime and construction waste as raw materials, bricks of different shapes and sizes can be produced by changing different molds. The equipment adopts hydraulic power system with stable performance and long service life. The product has high density, frost resistance, permeability resistance, sound insulation, heat insulation, good permeability resistance. The shape of the brick is of high precision and good flatness. It is an ideal environmental protection building materials equipment.

It is hydraulic pressure,easy operation.about 2000-2500 Bricks a day.The best choice for small factory to bulid small clay plant.diesel enginee or motor for your choose.

Technical Information

| Product Name | 1-15 Interlock brick making machine |

| working method | Hydraulic pressure |

| Dimension | 1000*1200*1700mm |

| Power | 6.3kw motor / 15HP diesel engine |

| Shipping cycle | 15-20s |

| Pressure | 16mpa |

| Production Capacity | 1600 blocks per day (8hours) |

| Features | Easy operation,hydraulic press |

| Power source | Electric motor or Diesel Engine |

| Operating staff | Only one worker |

| Molds | As customer’s requirement |

| Forming cycle | 10-15s |

| Forming way | Hydraulic press |

| Raw material | Clay ,soil ,cement or other construction dregs |

| Products | Interlock blocks ,pavers and hollow blocks |

Main Features

1) Diesel engine power is large, do not need three-phase electricity.

2) Equipped with mixer itself and powered by hydrulic pressure.

3) It can be towed to the work site by truck or car.

4) Using soil and cement as raw materials, saving each cost.

5) The blocks are interlocked in four directions: front and rear, up and down.

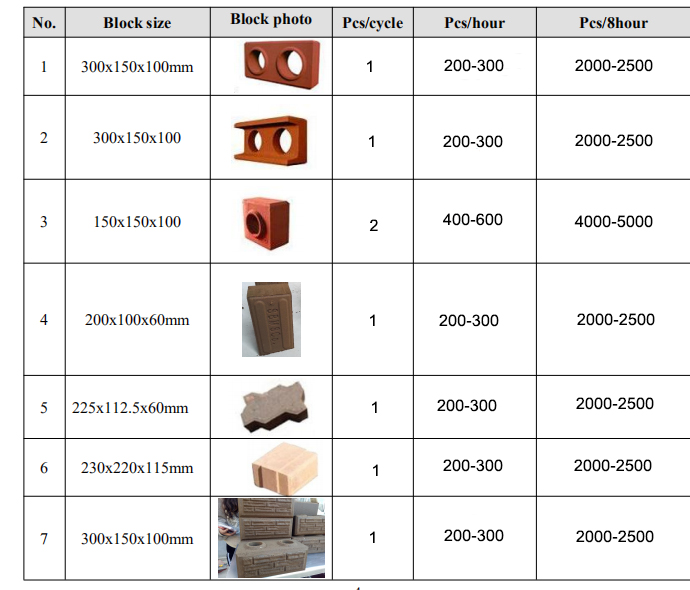

Production Capacity

Molds and Bricks

Machine Details

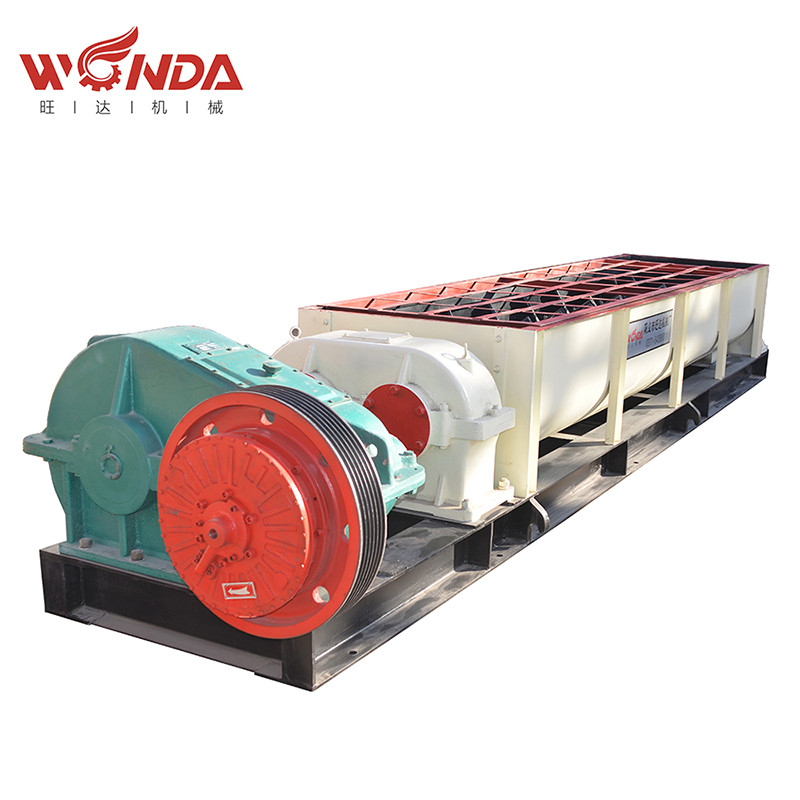

Complete Interlock Brick Production Line

Simple Interlock Brick Production Line

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for Factory wholesale Brick Making Machinery Automatically - WD1-15 Hydraulic brick pressing machine – Wangda , The product will supply to all over the world, such as: Munich, Brazil, azerbaijan, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!