Factory Price For Ecological Brick Machine - Automatic Pneumatic Brick Stacking Machine – Wangda

Factory Price For Ecological Brick Machine - Automatic Pneumatic Brick Stacking Machine – Wangda Detail:

Product Description

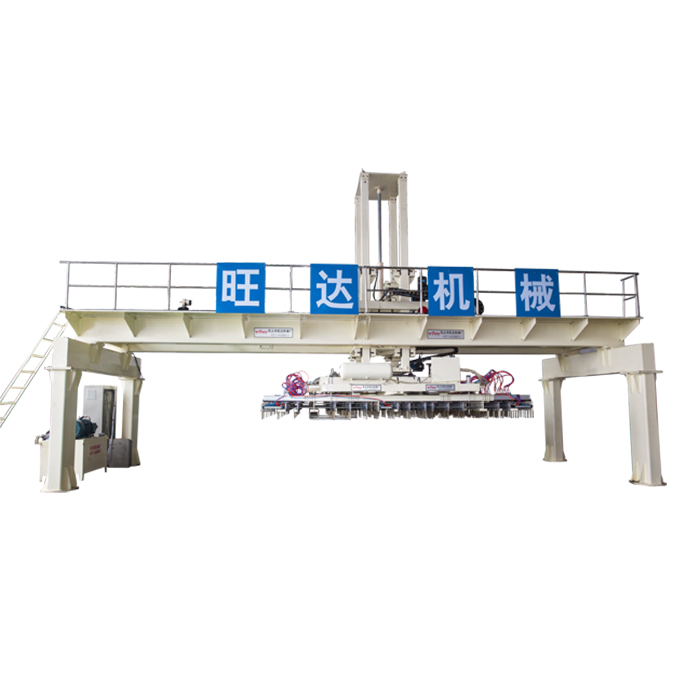

Automatic stacking machine & stacking robot are new brick automatic stacking, replace manual stacking way. It can greatly improve stacking efficiency and reduce labor cost. Depending on the size of the kiln, we should choose different types of stacking machine & stacking robot.

Advantage

1- Fast and efficient energy saving

2- Optimized high performance features make your production more efficient and accurate

3- Super suitable for a variety of brick types

Successful Projects

Product Parameters

| NO. | Type | Daily Production capacity | Main parameters |

| 1 |

3.3m One single fire kiln |

80000-100000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.3m

Kiln length: 132.6m Kiln car size:3.3mx3.42m |

| 2 |

3.6/3.7m One single fire kiln |

10000-150000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.6-3.7m

Kiln length: 141.2m Kiln car size:3.58mx3.84m |

| 3 |

3.6/3.7m One dry one fire kiln |

12000-180000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.6m

Kiln length: 111.6m Kiln car size:3.6mx3.72m |

| 4 |

3.6/3.7m Two dry two fire kilns |

25000-300000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.6m

Kiln length: 111.6m Kiln car size:3.6mx3.72m |

| 5 |

3.9m One single fire kiln |

130000-160000

(size calculated by 24×11.5x5cm) |

Kiln inner width:3.9m

Kiln length: 152.4m Kiln car size:3.9mx4.02m |

| … |

… |

… | … |

Operation Flow of Brick Setting Machine

The extruded strips are cut into separated brick strips by brick slitter;

The stripes are pushed through the cutting wires to the transitional bed ;

When the transitional bed is fully occupied, the bricks are pushed to the brick board;

The Lift Cylinder controls the chunk clamps down to reach the bricks, then the lift cylinder lifts the clamped bricks to a certain height.

Chunk puts down the bricks on the tunnel kiln car.

The Parts of Automatic Brick-Setting Machine

Product detail pictures:

Related Product Guide:

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for Factory Price For Ecological Brick Machine - Automatic Pneumatic Brick Stacking Machine – Wangda , The product will supply to all over the world, such as: Australia, Adelaide, San Diego, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!