The Hoffman kiln (known as a wheel kiln in China) is a type of kiln invented by German engineer Gustav Hoffman in 1856 for the continuous firing of bricks and tiles. The main structure consists of a closed circular tunnel, typically constructed from fired bricks. To facilitate production, multiple evenly spaced kiln doors are installed on the kiln walls. A single firing cycle (one firehead) requires 18 doors. To improve working conditions and allow finished bricks more time to cool, kilns with 22 or 24 doors were constructed, and two-fire kilns with 36 doors were also built. By controlling the air dampers, the firehead can be guided to move, enabling continuous production. As a type of thermal engineering kiln, the Hoffman kiln is also divided into preheating, firing, and cooling zones. However, unlike tunnel kilns, where the brick blanks are placed on kiln cars that move, the Hoffman kiln operates on the principle of “the blank moves, the fire stays still.” The three working zones—preheating, firing, and cooling—remain stationary, while the brick blanks move through the three zones to complete the firing process. The Hoffman kiln operates differently: the brick blanks are stacked inside the kiln and remain stationary, while the firehead is guided by air dampers to move, following the principle of “the fire moves, the blanks stay still.” Therefore, the preheating, firing, and cooling zones in the Hoffman kiln continuously change positions as the firehead moves. The area in front of the flame is for preheating, the flame itself is for firing, and the area behind the flame is for cooling. The working principle involves adjusting the air damper to guide the flame to sequentially fire the bricks stacked inside the kiln.

I. Operating Procedures:

Pre-ignition preparation: ignition materials such as firewood and coal. If using internal combustion bricks, approximately 1,100–1,600 kcal/kg of heat is required to burn one kilogram of raw material to 800–950°C. The ignition bricks can be slightly taller, with a moisture content of ≤6%. Qualified bricks should be stacked in three or four kiln doors. Brick stacking follows the principle of “tighter at the top and looser at the bottom, tighter at the sides and looser in the middle.” Leave a 15-20 cm fire channel between brick stacks. Ignition operations are best performed on straight sections, so the ignition stove should be built after the bend, at the second or third kiln door. The ignition stove has a furnace chamber and ash removal port. The coal feeding holes and windproof walls in the fire channels must be sealed to prevent cold air from entering.

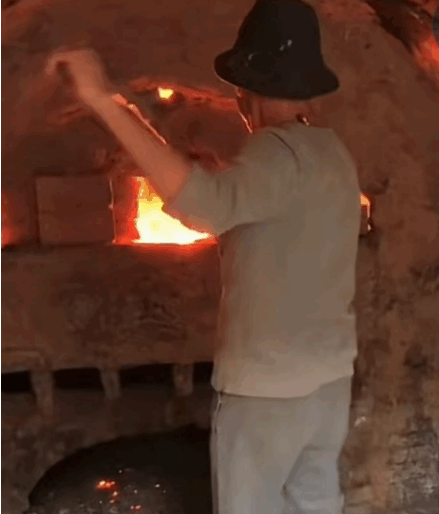

Ignition and heating: Before ignition, inspect the kiln body and air dampers for leaks. Turn on the fan and adjust it to create a slight negative pressure at the ignition stove. Ignite the wood and coal on the firebox to control the heating rate. Use a small fire to bake for 24–48 hours, drying the brick blanks while removing moisture from the kiln. Then, slightly increase the airflow to accelerate the heating rate. Different types of coal have different ignition points: brown coal at 300-400°C, bituminous coal at 400-550°C, and anthracite at 550-700°C. When the temperature reaches over 400°C, the coal inside the bricks begins to burn, and each brick becomes a heat source like a coal ball. Once the bricks start burning, the airflow can be further increased to reach the normal firing temperature. When the kiln temperature reaches 600°C, the air damper can be adjusted to redirect the flame to the next chamber, completing the ignition process.

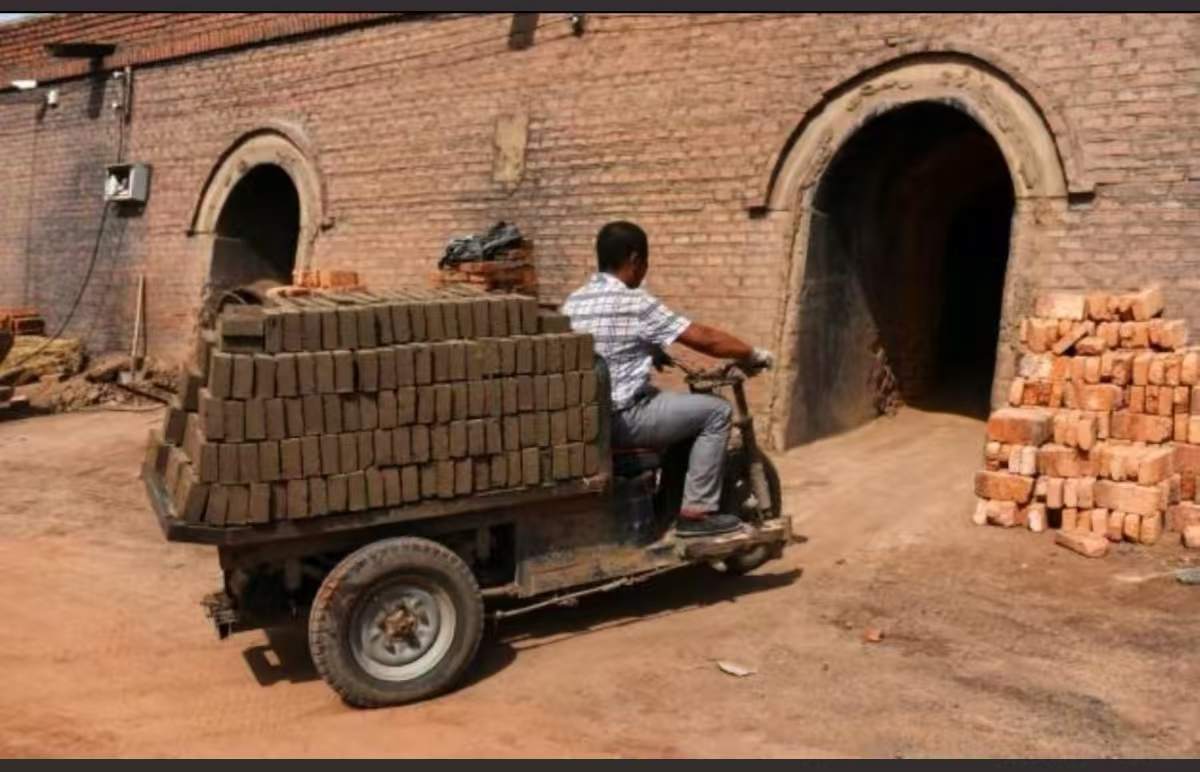

Kiln operation: The Hoffman kiln is used to fire clay bricks, with the firing rate at 4-6 kiln chambers per day. Since the firehead is constantly moving, the function of each kiln chamber also changes continuously. When in front of the firehead, the function is the preheating zone, with temperatures below 600°C, the air damper normally open at 60-70%, and negative pressure ranging from -20 to 50 Pa. While removing moisture, strict precautions must be taken to prevent brick blanks from cracking. The temperature zone between 600°C and 1050°C is the firing zone, where the brick blanks undergo transformation. Under high temperatures, the clay undergoes physical and chemical changes, transforming into finished bricks with ceramic properties. If the firing temperature is not reached due to insufficient fuel, fuel must be added in batches (coal powder ≤2 kg per hole each time), ensuring adequate oxygen supply (≥5%) for combustion, with the kiln pressure maintained at a slight negative pressure (-5 to -10 Pa). Maintain a constant high temperature for 4-6 hours to fully fire the brick blanks. After passing through the firing zone, the brick blanks are transformed into finished bricks. The coal feeding holes are then closed, and the bricks enter the insulation and cooling zone. The cooling rate must not exceed 50°C/h to prevent cracking due to rapid cooling. When the temperature drops below 200°C, the kiln door can be opened nearby, and after ventilation and cooling, the finished bricks are removed from the kiln, completing the firing process.

II. Important Notes

Brick stacking: “Three parts firing, seven parts stacking.” In the firing process, brick stacking is crucial. It is important to achieve “reasonable density,” finding the optimal balance between the number of bricks and the gaps between them. According to Chinese national standards, the optimal stacking density for bricks is 260 pieces per cubic meter. Brick stacking must adhere to the principles of “dense on top, sparse on bottom,” “dense on the sides, sparse in the middle,” and “leave space for airflow,” while avoiding an imbalance where the top is heavy and the bottom is light. The horizontal air duct should align with the exhaust vent, with a width of 15-20 cm. The vertical deviation of the brick pile must not exceed 2%, and strict measures must be taken to prevent the pile from collapsing.

Temperature Control: The preheating zone should be heated slowly; rapid temperature increases are strictly prohibited (rapid temperature increases can cause moisture to escape and crack the brick blanks). During the quartz metamorphic phase, the temperature must be maintained stable. If the temperature falls below the required temperature and coal needs to be added externally, concentrated coal addition is prohibited (to prevent localized overburning). Coal should be added in small amounts multiple times through a single hole, with each addition being 2 kg per batch, and each batch spaced at least 15 minutes apart.

Safety: The Hoffman kiln is also a relatively enclosed space. When carbon monoxide concentration exceeds 24 PPM, personnel must evacuate, and ventilation must be enhanced. After sintering, finished bricks must be manually removed. After opening the kiln door, first measure the oxygen content (oxygen content > 18%) before entering to work.

III. Common Faults and Troubleshooting

Common issues in Hoffman kiln production: moisture buildup in the preheating zone and collapse of wet brick stacks, primarily due to high moisture content in wet bricks and poor moisture drainage. Moisture drainage method: use dry brick blanks (with residual moisture content below 6%) and adjust the air damper to increase airflow, raising the temperature to approximately 120°C. Slow firing speed: Commonly referred to as “the fire won’t catch,” this is primarily due to oxygen-deficient combustion. Solutions for insufficient airflow: Increase the damper opening, raise the fan speed, repair kiln body gaps, and clean accumulated debris from the flue. In summary, ensure sufficient oxygen is supplied to the combustion chamber to achieve oxygen-rich combustion and rapid temperature rise conditions. Brick body discoloration (yellowing) due to insufficient sintering temperature: Solution: Appropriately increase fuel quantity and raise firing temperature. Black-hearted bricks can form for several reasons: excessive internal combustion additives, oxygen deficiency in the kiln creating a reducing atmosphere (O₂ < 3%), or bricks not being fully fired. Solutions: Reduce the internal fuel content, increase ventilation for sufficient oxygen combustion, and appropriately extend the high-temperature constant-temperature duration to ensure the bricks are fully fired. Brick deformation (overfiring) is primarily caused by localized high temperatures. Solutions include opening the front air damper to move the flame forward and opening the rear fire cover to introduce cool air into the kiln to lower the temperature.

The Hoffman kiln has been in use for 169 years since its invention and has undergone numerous improvements and innovations. One such innovation is the addition of a kiln bottom air duct to introduce dry hot air (100°C–300°C) into the drying chamber during the single-firing wheel kiln process. Another innovation is the use of internally fired bricks, which were invented by the Chinese. After coal is crushed, it is added to the raw materials according to the required calorific value (approximately 1240 kcal/kg of raw material is needed to raise the temperature by 1°C, equivalent to 0.3 kcal). The “Wanda” brick factory’s feeding machine can mix the coal and raw materials in the correct proportions. The mixer thoroughly blends the coal powder with the raw materials, ensuring that the calorific value deviation is controlled within ±200 kJ/kg. Additionally, temperature control and PLC systems are installed to automatically adjust the air damper flow rate and coal feeding rate. This enhances the level of automation, better ensuring the three stability principles of Hoffman kiln operation: “stable air pressure, stable temperature, and stable flame movement.” Normal operation requires flexible adjustments based on the conditions inside the kiln, and careful operation can produce qualified finished bricks.

Post time: Jun-21-2025