I. Introduction:

II. Structure:

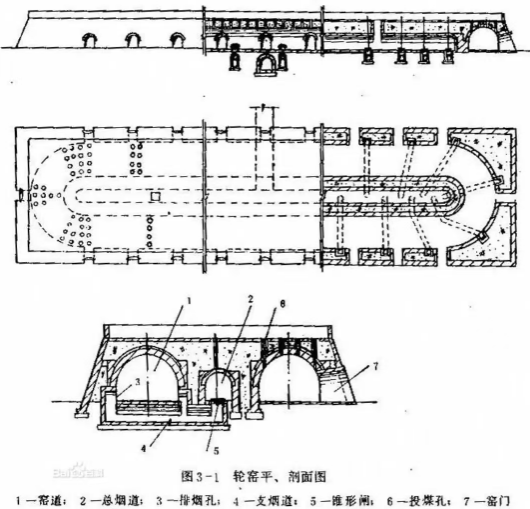

After bricks are stacked in a kiln chamber, paper barriers must be pasted to seal the individual chamber. When the fire position needs to move, the damper of that chamber is opened to create negative pressure inside, which draws the flame front into the chamber and burns the paper barrier. In special cases, a fire hook can be used to tear the paper barrier of the previous chamber. Each time the fire position moves to a new chamber, subsequent chambers enter the next stage in sequence. Usually, when a damper is just opened, the chamber enters the preheating and temperature-rising stage; chambers 2-3 doors away enter the high-temperature firing stage; chambers 3-4 doors away enter the insulation and cooling stage, and so on. Each chamber continuously changes its role, forming a continuous cyclic production with a moving flame front. The flame travel speed is affected by air pressure, air volume, and fuel calorific value. Additionally, it varies with brick raw materials (4-6 meters per hour for shale bricks, 3-5 meters per hour for clay bricks). Therefore, the firing speed and output can be adjusted by controlling air pressure and volume via dampers and adjusting fuel supply. The moisture content of bricks also directly affects the flame travel speed: a 1% decrease in moisture content can increase the speed by about 10 minutes. The sealing and insulation performance of the kiln directly affect fuel consumption and finished brick output.

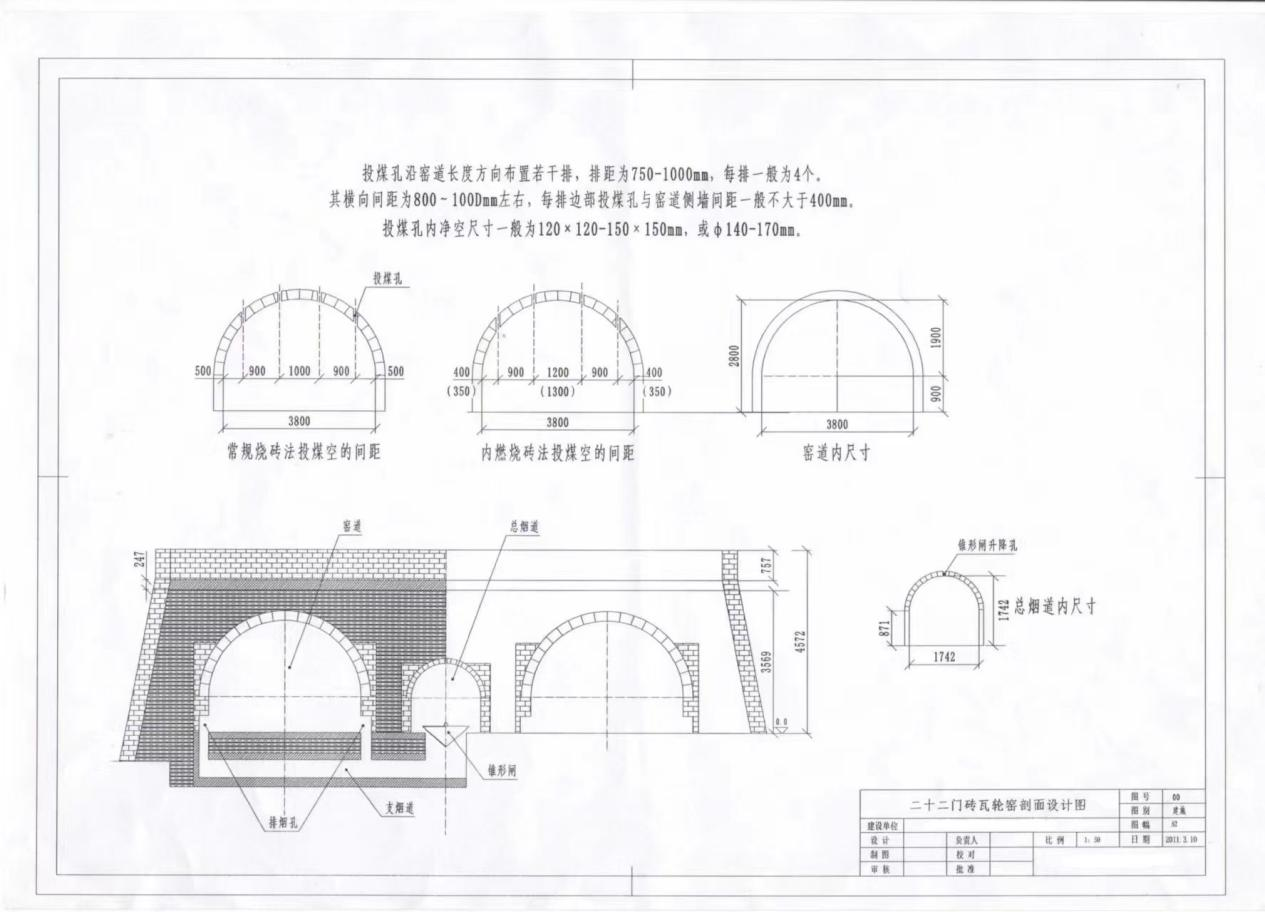

First, based on the output requirement, determine the net internal width of the kiln. Different internal widths require different air volumes. Based on the required air pressure and volume, determine the specifications and sizes of the kiln’s air inlets, flues, dampers, air pipes, and main air ducts, and calculate the total width of the kiln. Then, determine the fuel for brick firing—different fuels require different combustion methods. For natural gas, positions for burners must be pre-reserved; for heavy oil (used after heating), nozzle positions must be reserved. Even for coal and wood (sawdust, rice husks, peanut shells, and other combustible materials with heat value), the methods differ: coal is crushed, so coal feeding holes can be smaller; for easy wood feeding, the holes should be larger accordingly. After designing based on the data of each kiln component, construct the kiln construction drawings.

III. Construction Process:

① Geological survey: Ascertain the depth of the groundwater layer and soil bearing capacity (required to be ≥150kPa). For soft foundations, use replacement methods (rubble foundation, pile foundation, or compacted 3:7 lime-soil).

② After foundation treatment, build the kiln flue first and apply waterproof and moisture-proof measures: 抹 a 20mm thick waterproof mortar layer, then perform waterproof treatment.

③ The kiln foundation uses a reinforced concrete raft slab, with φ14 steel bars bound in a 200mm bidirectional grid. The width is as per design requirements, and the thickness is approximately 0.3-0.5 meters.

④ Expansion joints: Arrange one expansion joint (30mm wide) for every 4-5 chambers, filled with asphalted hemp for waterproof sealing.

Kiln Body Construction:

① Material preparation: After the foundation is completed, level the site and prepare materials. Kiln materials: The two ends of the Hoffman kiln are semicircular; special-shaped bricks (trapezoidal bricks, fan-shaped bricks) are used at the bends. If the inner kiln body is built with firebricks, fire clay is required, especially for arch bricks (T38, T39, commonly called “blade bricks”) used at the air inlets and arch tops. Prepare formwork for the arch top in advance.

② Setting out: On the treated foundation, mark the kiln’s centerline first, then determine and mark the kiln wall edges and kiln door positions based on the underground flue and air inlet positions. Mark six straight lines for the kiln body and arc lines for the end bends based on the net internal width.

③ Masonry: First build the flues and air inlets, then lay the bottom bricks (requiring staggered joint masonry with full mortar, no continuous joints, to ensure sealing and prevent air leakage). The sequence is: build straight walls along the marked foundation lines, transitioning to the bends, which are built with trapezoidal bricks (allowable error ≤3mm). As per design requirements, build connecting support walls between the inner and outer kiln walls and fill with insulation materials. When straight walls are built to a certain height, lay arch angle bricks (60°-75°) to start building the arch top. Place the arch formwork (allowable arc deviation ≤3mm) and build the arch top symmetrically from both sides to the center. Use arch bricks (T38, T39) for the arch top; if ordinary bricks are used, ensure close 贴合 with the formwork. When building the last 3-6 bricks of each ring, use wedge-shaped locking bricks (thickness difference 10-15mm) and hammer them tight with a rubber hammer. Reserve observation ports and coal feeding ports on the arch top as per design requirements.

IV. Quality Control:

b. Flatness: Check with a 2-meter straightedge; allowable unevenness ≤3mm.

c. Sealing: After kiln masonry is completed, conduct a negative pressure test (-50Pa); leakage rate ≤0.5m³/h·m².

Post time: Aug-05-2025