The most widely adopted kiln type in the brick-making industry today is the tunnel kiln. The concept of the tunnel kiln was first proposed and initially designed by the French, though it was never constructed. The first tunnel kiln specifically designed for brick production was created by German engineer 2—book in 1877, who also filed a patent for it. With the widespread adoption of tunnel kilns, numerous innovations emerged. Based on the internal net width, they are categorized into small-section (≤2.8 meters), medium-section (3–4 meters), and large-section (≥4.6 meters). By kiln type, they include micro-dome type, flat ceiling type, and ring-shaped moving type. By operating method, they include roller kilns and shuttle kilns. Push-plate kilns. Based on the type of fuel used: there are those using coal as fuel (the most common), those using gas or natural gas (used for firing non-refractory bricks and plain wall bricks, primarily for high-end bricks), those using heavy oil or mixed energy sources, and those using biomass fuel, etc. In summary: any tunnel-type kiln operating in a counter-current configuration, divided along its length into preheating, sintering, and cooling sections, with products moving in the opposite direction to the gas flow, is a tunnel kiln.

Tunnel kilns are widely used as thermal engineering kilns for firing building bricks, refractory bricks, ceramic tiles, and ceramics. In recent years, tunnel kilns have also been used to fire water purification agents and raw materials for lithium batteries. Tunnel kilns have a wide range of applications and come in many types, each with its own characteristics. Today, we will focus on the cross-section tunnel kiln used for firing building bricks.

1. Principle: As a hot kiln, the tunnel kiln naturally requires a heat source. Any combustible material that can generate heat can be used as fuel for the tunnel kiln (different fuels may result in variations in local construction). The fuel burns in the combustion chamber inside the kiln, producing high-temperature flue gas. Under the influence of the fan, the high-temperature gas flow moves in the opposite direction to the products being fired. The heat is transferred to the brick blanks on the kiln car, which moves slowly along the tracks into the kiln. The bricks on the kiln car also continue to heat up. The section before the combustion chamber is the preheating zone (approximately before the tenth car position). The brick blanks are gradually heated and warmed up in the preheating zone, removing moisture and organic matter. As the kiln car enters the sintering zone, the bricks reach their maximum firing temperature (850°C for clay bricks and 1050°C for shale bricks) using the heat released from fuel combustion, undergoing physical and chemical changes to form a dense structure. This section is the firing zone (also the high-temperature zone) of the kiln, spanning approximately the 12th to 22nd positions. After passing through the firing zone, the bricks undergo a certain period of insulation before entering the cooling zone. In the cooling zone, the fired products come into contact with a large amount of cold air entering through the kiln outlet, gradually cooling down before exiting the kiln, thus completing the entire firing process.

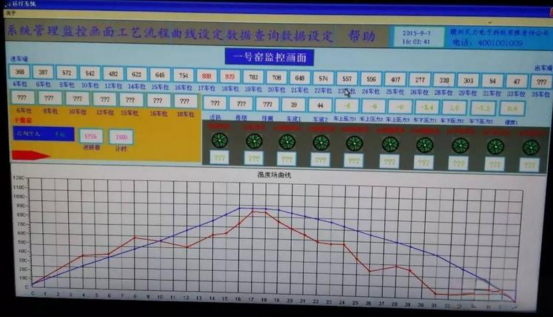

II. Construction: Tunnel kilns are thermal engineering kilns. They have a wide temperature range and high structural requirements for the kiln body. (1) Foundation preparation: Clear debris from the construction area and ensure three utilities and one level surface. Ensure water supply, electricity, and a level ground surface. The slope must meet drainage requirements. The foundation should have a bearing capacity of 150 kN/m². If encountering soft soil layers, use the replacement method (stone masonry base or compacted lime-soil mixture). After foundation trench treatment, use reinforced concrete as the kiln foundation. A sturdy foundation ensures bearing capacity and kiln stability. (2) Kiln Structure The inner walls of the kiln in high-temperature zones should be constructed using firebrick. The outer walls may use ordinary bricks, with insulation treatment between the bricks (using rock wool, aluminum silicate fiber blankets, etc.) to reduce heat loss. The inner wall thickness is 500 mm, and the outer wall thickness is 370 mm. Expansion joints should be left according to design requirements. The masonry should have full mortar joints, with refractory bricks laid in staggered joints (mortar joints ≤ 3 mm) and ordinary bricks with mortar joints of 8–10 mm. Insulation materials should be evenly distributed, fully packed, and sealed to prevent water ingress. (3) Kiln Bottom The kiln bottom should be a flat surface for the kiln car to move on. The moisture-resistant layer must have sufficient load-bearing capacity and thermal insulation properties, as the kiln car moves along the tracks. In a tunnel kiln with a cross-sectional width of 3.6 meters, each car can load approximately 6,000 wet bricks. Including the kiln car’s self-weight, the total load is around 20 tons, and the entire kiln track must withstand a single car weight of over 600 tons. Therefore, the track laying must not be done carelessly. (4) The kiln roof typically has two types: slightly arched and flat. The arched roof is a traditional masonry method, while the flat roof uses refractory castable material or lightweight refractory bricks for the ceiling. Nowadays, many use silicon aluminum fiber ceiling blocks. Regardless of the material used, it must ensure refractory temperature and sealing, and observation holes must be installed at appropriate locations according to design requirements. Coal feeding holes, air duct holes, etc. (5) Combustion system: a. Tunnel kilns burning wood and coal do not have combustion chambers in the high-temperature zone of the kiln, which are constructed using refractory bricks, and have fuel feeding ports and ash discharge ports. b. With the promotion of internal combustion brick technology, separate combustion chambers are no longer required, as the bricks retain heat. if insufficient heat is available, additional fuel can be added through coal-feeding holes on the kiln roof. c. Kilns burning natural gas, coal gas, liquefied petroleum gas, etc., have gas burners on the kiln sides or roof (depending on the fuel type), with burners distributed reasonably and uniformly to facilitate temperature control within the kiln. (6) Ventilation system: a. Fans: including supply fans, exhaust fans, dehumidification fans, and balancing fans. Cooling fans. Each fan is located in a different position and serves a different function. The supply fan introduces air into the combustion chamber to provide sufficient oxygen for combustion, the exhaust fan removes flue gases from the kiln to maintain a certain negative pressure inside the kiln and ensure smooth flue gas flow, and the dehumidification fan removes moist air from wet brick blanks outside the kiln. b. Air ducts: These are divided into flue ducts and air ducts. Flue ducts primarily remove flue gases and wet air from the kiln. Air ducts are available in masonry and pipe types and are responsible for supplying oxygen to the combustion zone. c. Air dampers: Installed on the air ducts, they are used to regulate airflow and kiln pressure. By adjusting the opening size of the air dampers, the temperature distribution and flame position inside the kiln can be controlled. (7) Operating system: a. Kiln car: The kiln car has a movable kiln bottom with a tunnel-like structure. Brick blanks move slowly on the kiln car, passing through the preheating zone, sintering zone, Insulation zone, cooling zone. The kiln car is made of steel structure, with dimensions determined by the net width inside the kiln, and ensures sealing. b. Transfer car: At the kiln mouth, the transfer car relocates the kiln car. The kiln car is then sent to the storage zone, then to the drying zone, and finally to the sintering zone, with the finished products being transported to the unloading zone. c. Traction equipment includes track traction machines, hydraulic lifting machines, step machines, and kiln-mouth traction machines. Through various devices at different locations, the kiln car is pulled along the tracks to move, achieving a series of actions such as brick storage, drying, sintering, unloading, and packaging. (8) Temperature control system: Temperature detection involves installing thermocouple temperature sensors at different positions inside the kiln to monitor the kiln temperature in real-time. Temperature signals are transmitted to the control room, where operators adjust the air intake volume and combustion value based on the temperature data. Pressure monitoring involves installing pressure sensors at the kiln head, kiln tail, and critical locations inside the kiln to monitor changes in kiln pressure in real-time. By adjusting the air dampers in the ventilation system, the kiln pressure is maintained at a stable level.

III. Operation: After the main body of the tunnel kiln and its配套equipment have been installed, it is time to prepare for the ignition operation and normal use. Operating a tunnel kiln is not as simple as changing a light bulb or flipping a switch; successfully firing a tunnel kiln requires scientific expertise. Rigorous control, the transmission of experience, and coordination across multiple aspects are all crucial. Detailed operational procedures and solutions for issues that may arise will be discussed later. For now, let’s briefly introduce the operational methods and processes of the tunnel kiln: “Inspection: First, check the kiln body for any cracks. Check if the expansion joint seals are tight. Push a few empty kiln cars around a few times to check if the track, top car machine, transfer car, and other handling equipment are functioning normally. For kilns using natural gas or coal gas as fuel, first ignite the flame to ensure it burns normally. Check if all fans are operating properly. Kiln drying methods vary depending on the type of fuel used. However, the objective is consistent: to slowly remove moisture retained in the kiln structure during construction through drying, preventing sudden heating and cracking of the kiln body. a. Low-temperature stage (0–200°C): Dry at low heat for one or two days, with a temperature rise rate ≤10°C per hour. b. Medium-temperature stage (200–600°C): Temperature rise rate 10–15°C per hour, and bake for two days. c. High-temperature stage (600°C and above): increase the temperature at the normal rate of 20°C per hour until the firing temperature is reached, and maintain for one day. During the firing process, monitor the expansion of the kiln body at all times and periodically remove moisture. (3) Ignition: Using fuels such as natural gas or coal gas is simple. Today, we will use coal, wood, etc. (3) As an example, first construct a kiln cart for easy ignition: place firewood, coal, and other flammable materials on the kiln cart. First, activate the fan to create negative pressure inside the kiln, directing the flame toward the brick blanks. Use a fire starter rod. Ignite the wood and coal, and gradually increase the temperature by adjusting the airflow and pressure until the brick blanks reach the firing temperature. Once the brick blanks reach the firing temperature, begin feeding new cars into the kiln from the front and slowly move them toward the sintering zone. Push the kiln car and kiln car forward to complete ignition. The temperature of the newly ignited tunnel kiln must be monitored at all times to ensure that the firing process is completed according to the designed temperature curve. ④) Production operations: Brick arrangement: Arrange the bricks on the kiln car according to design requirements, ensuring appropriate gaps and air channels between bricks to facilitate smooth flue gas flow. Parameter settings: Determine the temperature, air pressure, airflow, and kiln car travel speed. During production operations, these parameters are adjusted and optimized to ensure the high quality of the finished products. Operational Procedures: During tunnel kiln operation, temperatures, pressures, and flue gas parameters at each workstation must be continuously monitored. The preheating zone should be heated slowly (approximately 50–80% per meter) to prevent brick cracking. The firing zone should maintain a high and constant temperature, with a temperature difference of ≤±10°C to ensure the bricks are fully fired. The cooling zone can utilize a waste heat recovery design (energy-saving and emissions-reducing) to transfer thermal energy to the drying zone for brick drying. Additionally, the kiln car must be advanced uniformly according to design requirements. To ensure product quality, air pressure and airflow must be adjusted based on the design temperature curve. Maintain stable kiln pressure (slight positive pressure of 10–20 Pa in the firing zone and negative pressure of -10 to -50 Pa in the preheating zone) based on monitoring data. Kiln exit: When the kiln car reaches the tunnel kiln exit, the brick blanks have completed firing and cooled to an appropriate temperature. The kiln car carrying the finished bricks can then be transported to the unloading area via handling equipment, inspected, and unloaded to complete the tunnel kiln firing process. The empty kiln car then returns to the brick stacking position in the workshop. The process is then repeated for the next stacking and firing cycle.

Since its invention, the brick-firing tunnel kiln has undergone multiple structural optimizations and technological innovations, gradually improving environmental protection standards and automation levels. In the future, intelligentization, greater environmental friendliness, and resource recycling will dominate technological directions, driving the brick and tile industry toward high-end manufacturing.

Post time: Jun-12-2025