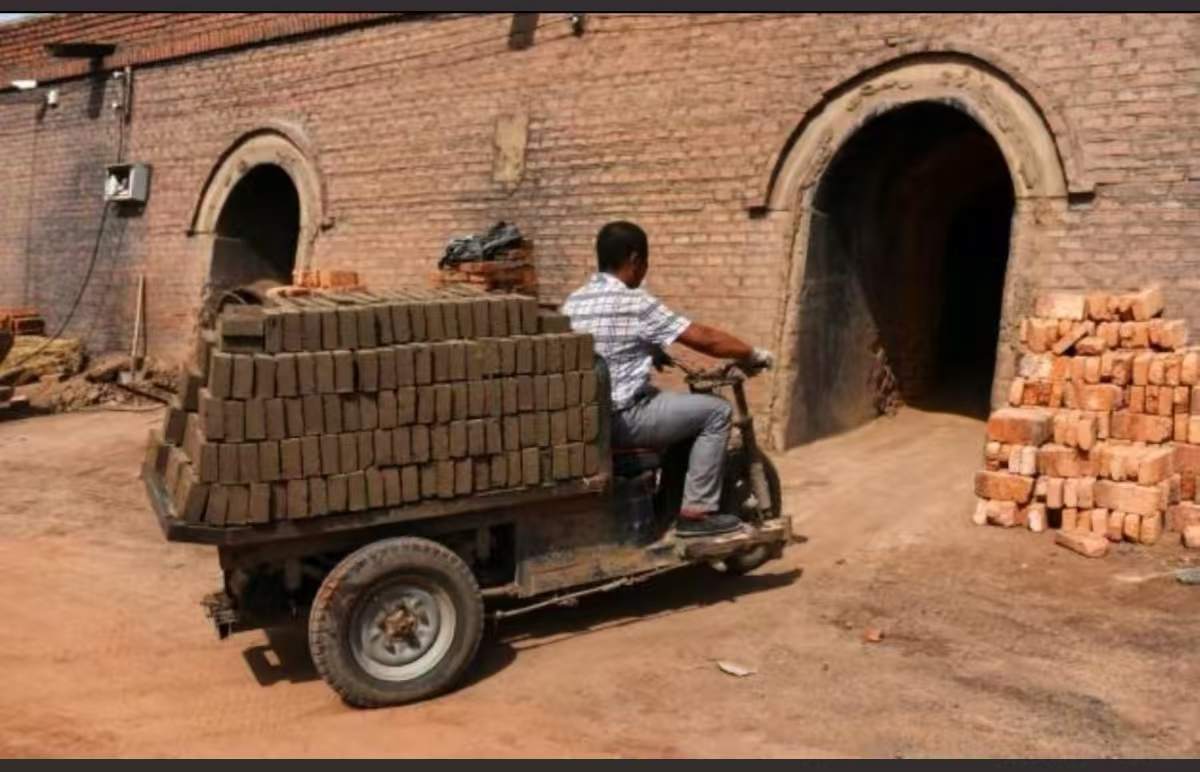

I-Hoffman kiln (eyaziwa ngokuthi i-wheel kiln e-China) iwuhlobo lweziko elasungulwa unjiniyela waseJalimane u-Gustav Hoffman ngo-1856 ukuze kuqhunyiswe izitini nama-tiles okuqhubekayo. Isakhiwo esiyinhloko siqukethe umhubhe oyindilinga ovaliwe, ngokuvamile owakhiwa ngezitini ezibasiwe. Ukwenza kube lula ukukhiqiza, iminyango eminingi yehhashi enezikhala ezilinganayo ifakwa ezindongeni zomlilo. Umjikelezo wokudubula owodwa (isiqhumane esisodwa) sidinga iminyango engu-18. Ukuze kuthuthukiswe izimo zokusebenza futhi kuvunyelwe izitini eziqediwe isikhathi esengeziwe sokupholisa, kwakhiwa ohonela abanezicabha ezingu-22 noma ezingu-24, kwakhiwa namahhayela omlilo amabili aneminyango engu-36. Ngokulawula ama-dampers omoya, i-firehead ingaqondiswa ukuthi ihambe, inike amandla ukukhiqizwa okuqhubekayo. Njengohlobo lweziko lobunjiniyela obushisayo, iziko likaHoffman nalo lihlukaniswe ngokwezindawo zokushisa, ukudubula, kanye nezokupholisa. Nokho, ngokungafani neziko lomhubhe, lapho izimbobo zezitini zibekwa khona ezimotweni zokushisa ezinyakazayo, iziko lakwaHoffman lisebenza ngesimiso “sokuhamba okungenalutho, umlilo awunyakazi.” Izindawo ezintathu okusetshenzwa kuzo—ukushisa, ukudubula, nokupholisa—zihlala zimile, kuyilapho izikhala zezitini zihamba phakathi kwezindawo ezintathu ukuze kuqedelwe inqubo yokudubula. Ihhavini likaHoffman lisebenza ngendlela ehlukile: izikhala zezitini zimbondelene ngaphakathi kuhho futhi zihlale zimile, kuyilapho i-firehead iholwa ama-air dampers ukuze ihambe, ilandela isimiso sokuthi "umlilo uhamba, izikhala zihlala zinganyakazi." Ngakho-ke, izindawo zokushisa, ukudubula, kanye nokupholisa kuhhavini ye-Hoffman zishintsha njalo izikhundla njengoba i-firehead ihamba. Indawo ephambi kwelangabi eyokushisisa, ilangabi ngokwalo elokudubula, futhi indawo engemuva kwelangabi elokupholisa. Isimiso sokusebenza sihilela ukulungisa isibambisi somoya ukuze siqondise ilangabi ukuze lishise ngokulandelana izitini ezinqwabelene ngaphakathi kuhhavini.

I. Izinqubo Zokusebenza:

Ukulungiselela ngaphambi kokuvutha: izinto zokubasa njengezinkuni namalahle. Uma usebenzisa izitini ezivuthayo zangaphakathi, cishe u-1,100–1,600 kcal/kg wokushisa uyadingeka ukuze kushiswe ikhilogremu eyodwa yezinto ezingavuthiwe zibe ngu-800–950°C. Izitini zokubasa zingaba zinde kancane, ezinomswakama ongu-≤6%. Izitini ezifanelekayo kufanele zipakishwe eminyango yeziko ezintathu noma ezine. Ukupakishwa kwezitini kulandela isimiso “sokuqina phezulu nokuxega phansi, kuqine emaceleni futhi kuxege phakathi nendawo.” Shiya ishaneli yomlilo engu-15-20 cm phakathi kwezitaki zezitini. Imisebenzi yokuthungela yenziwa kahle kakhulu ezigabeni eziqondile, ngakho-ke isitofu sokuthungela kufanele sakhiwe ngemva kokugoba, emnyango wesibili noma wesithathu weziko. Isitofu somlilo sinegumbi lomlilo kanye nembobo yokukhipha umlotha. Imigodi yokudla kwamalahle kanye nezindonga ezingangenwa umoya eziteshini zomlilo kumele zivalwe ukuze kuvinjwe umoya obandayo ukuthi ungangeni.

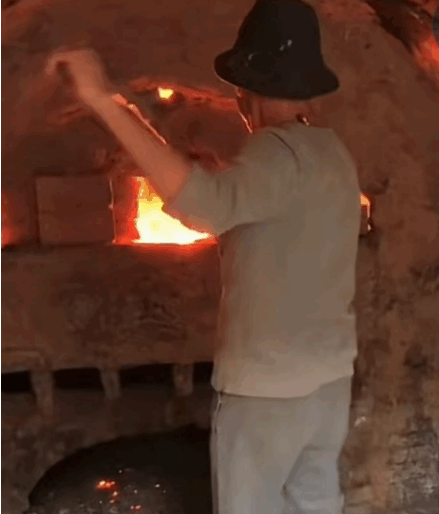

Ukuthungela nokushisisa: Ngaphambi kokuthungela, hlola umzimba weziko kanye nezinto ezinciphisa umoya ukuze zivuze. Vula isiphephetha-moya bese usilungisa ukuze udale ukucindezela okuncane okunegethivu esitofini sokushisa. Kokhela izinkuni namalahle ebhokisini lomlilo ukuze ulawule izinga lokushisa. Sebenzisa umlilo omncane ukubhaka amahora angama-24-48, womisa izikhala zezitini ngenkathi ususa umswakama kuhhavini. Bese, ukwandisa kancane ukugeleza komoya ukuze usheshise izinga lokushisa. Izinhlobo ezahlukene zamalahle zinamaphoyinti okuvutha ahlukene: amalahle ansundu ku-300-400°C, amalahle e-bituminous ku-400-550°C, kanye ne-anthracite ku-550-700°C. Lapho izinga lokushisa lifinyelela ngaphezu kuka-400 ° C, amalahle ngaphakathi kwezitini aqala ukushisa, futhi isitini ngasinye siba umthombo wokushisa njengebhola lamalahle. Uma izitini ziqala ukuvutha, ukugeleza komoya kungandiswa ngokuqhubekayo ukuze kufinyelele izinga lokushisa elivamile lokudubula. Lapho izinga lokushisa lomlilo lifinyelela ku-600 ° C, i-damper yomoya ingashintshwa ukuze iqondise kabusha ilangabi ekamelweni elilandelayo, igcwalise inqubo yokuthungela.

Ukushiswa kweziko: Ihhavini likaHoffman lisetshenziselwa ukushisa izitini zobumba, izinga lokudubula libe ngamakamelo ama-4-6 ngosuku. Njengoba i-firehead ihamba njalo, umsebenzi wegumbi ngalinye lomlilo nawo ushintsha ngokuqhubekayo. Uma uphambi kwekhanda lomlilo, umsebenzi uyindawo yokushisa, enamazinga okushisa angaphansi kuka-600 ° C, i-air damper ngokuvamile ivula ku-60-70%, nokucindezela okungalungile okuvela ku--20 kuya ku-50 Pa. Ngenkathi kukhishwa umswakama, izinyathelo eziqinile kufanele zithathwe ukuze kuvinjelwe izikhala zezitini ekuqhekekeni. Indawo yokushisa ephakathi kuka-600°C no-1050°C indawo yokudubula, lapho izikhala zezitini zishintsha khona. Ngaphansi kwamazinga okushisa aphezulu, ubumba luba nezinguquko zomzimba namakhemikhali, luguqule zibe izitini eziqediwe ezinezakhiwo ze-ceramic. Uma izinga lokushisa lokudubula lingafinyelelwanga ngenxa yephethiloli enganele, uphethiloli kufanele wengezwe ngamaqoqo (i-powder yamalahle ≤2 kg emgodini ngamunye isikhathi ngasinye), ukuqinisekisa ukutholakala kwe-oksijeni okwanele (≥5%) ukuze kushiswe, nokucindezela komlilo kugcinwa ekucindezelweni okuncane okungalungile (-5 kuya ku-10 Pa). Gcina izinga lokushisa eliphezulu elingashintshi amahora angu-4-6 ukuze ushise ngokugcwele izikhala zezitini. Ngemva kokudlula endaweni yokudubula, izikhala zezitini ziguqulwa zibe izitini eziqediwe. Khona-ke imigodi yokudla kwamalahle iyavalwa, futhi izitini zingena endaweni yokushisa kanye nendawo yokupholisa. Izinga lokupholisa akumele lidlule ku-50°C/h ukuvimbela ukuqhekeka ngenxa yokupholisa ngokushesha. Lapho izinga lokushisa lehla ngaphansi kuka-200 ° C, umnyango womlilo ungavulwa eduze, futhi ngemva kokungenisa umoya nokupholisa, izitini eziqediwe zisuswa kuhhavini, ziqedele inqubo yokudubula.

II. Amanothi Abalulekile

Ukupakishwa kwezitini: “Izingxenye ezintathu ezidubulayo, izingxenye eziyisikhombisa zinqwabelene.” Enqubweni yokudubula, ukunqwabelana kwezitini kubalulekile. Kubalulekile ukufeza "ukuminyana okunengqondo," ukuthola ibhalansi efanele phakathi kwenani lezitini kanye nezikhala phakathi kwazo. Ngokwezindinganiso zikazwelonke zaseShayina, ukuminyana okufanelekile kwezitini yizingcezu ezingama-260 nge-cubic meter ngayinye. Ukupakisha izitini kufanele kuhambisane nezimiso "zokuminyene phezulu, kuncane phansi," "kuminyene ezinhlangothini, kugqame phakathi," futhi "kushiye isikhala sokugeleza komoya," kuyilapho ugwema ukungalingani lapho okungaphezulu kusinda futhi okuphansi kukhanya. I-air duct evundlile kufanele ihambisane ne-exhaust vent, ngobubanzi buka-15-20 cm. Ukuchezuka okuqondile kwenqwaba yezitini akumele kudlule u-2%, futhi izinyathelo eziqinile kufanele zithathwe ukuvimbela inqwaba ukuthi ingawi.

Ukulawulwa Kwezinga Lokushisa: Indawo yokushisisa kufanele ifudunyezwe kancane; ukwanda kwezinga lokushisa ngokushesha akuvunyelwe ngokuqinile (ukwanda kwezinga lokushisa ngokushesha kungabangela umswakama ukuba uphume futhi uqhekeke izikhala zezitini). Phakathi nesigaba se-quartz metamorphic, izinga lokushisa kufanele ligcinwe lizinzile. Uma izinga lokushisa liwela ngaphansi kwezinga lokushisa elidingekayo futhi amalahle adinga ukwengezwa ngaphandle, ukuhlanganisa amalahle agxilile akuvunyelwe (ukuvimbela ukushiswa ngokweqile kwendawo). Amalahle kufanele engezwe ngamanani amancane izikhathi eziningi ngembobo eyodwa, ukuhlanganisa ngakunye kube ngu-2 kg ngeqeqebana ngalinye, futhi iqoqo ngalinye lihlukaniswe okungenani imizuzu eyi-15.

Ukuphepha: Iziko likaHoffman nalo liyindawo evalekile uma kuqhathaniswa. Uma ukugxila kwe-carbon monoxide kudlula ama-24 PPM, izisebenzi kufanele ziphume, futhi komoya kufanele kuthuthukiswe. Ngemuva kokugcoba, izitini eziqediwe kufanele zisuswe ngesandla. Ngemva kokuvula umnyango kahno, qala ulinganise okuqukethwe komoyampilo (okuqukethwe komoyampilo > 18%) ngaphambi kokungena emsebenzini.

III. Amaphutha ajwayelekile kanye nokuxazulula izinkinga

Izinkinga ezijwayelekile ekukhiqizweni kweziko lika-Hoffman: ukunqwabelana komswakama endaweni yokushisa kuqala kanye nokuwa kwezitaki zezitini ezimanzi, ngokuyinhloko ngenxa yokuqukethwe okuphezulu komswakamo ezitini ezimanzi kanye nokungagelezi kahle komswakama. Indlela yokukhipha umswakama: sebenzisa izikhala zezitini ezomile (ezinomswakama osalayo ongaphansi kuka-6%) futhi ulungise isidambisi-moya ukuze ukhulise ukugeleza komoya, ukhuphule izinga lokushisa libe cishe ku-120°C. Isivinini sokudubula esinensayo: Okuvame ukubizwa ngokuthi “umlilo ngeke ubambe,” lokhu ngokuyinhloko kubangelwa ukusha okuntula umoya-mpilo. Izixazululo zokungagelezi komoya okunganele: Khulisa ukuvuleka komswakama, ukhuphule isivinini sefeni, lungisa izikhala zomzimba eziko, futhi hlanza imfucumfucu enqwabelene evela kumtshingo. Kafushane, qiniseka ukuthi kunikezwa umoya-mpilo owanele ekamelweni elivuthayo ukuze kuzuzwe ukuvutha okucebile komoyampilo kanye nezimo zokushisa ezikhuphuka ngokushesha. Ukushintsha umbala womzimba wezitini (okuphuzi) ngenxa yezinga lokushisa le-sintering elinganele: Isixazululo: Khulisa ngokufanelekile inani likaphethiloli futhi ukhuphule izinga lokushisa lokudubula. Izitini ezinenhliziyo emnyama zingakha ngenxa yezizathu eziningana: izithasiselo zokuvutha zangaphakathi ngokweqile, ukuntuleka komoya-mpilo kuhnu okudala umoya wokunciphisa (O₂ <3%), noma izitini ezingashiswanga ngokugcwele. Izixazululo: Nciphisa okuqukethwe kukaphethiloli wangaphakathi, khulisa umoya wokungenisa umoya owanele wokushisa komoyampilo, futhi wandise ngokufanelekile ubude bezinga lokushisa elingaguquki eliphezulu ukuze uqinisekise ukuthi izitini zishiswa ngokugcwele. Ukuguqulwa kwezitini (ukushisa ngokweqile) kubangelwa ikakhulukazi izinga lokushisa eliphezulu lendawo. Izixazululo zihlanganisa ukuvula isidambisi-moya sangaphambili ukuhambisa ilangabi liye phambili nokuvula ikhava yomlilo yangemuva ukwethula umoya opholile kuhn ukuze wehlise izinga lokushisa.

I-Hoffman kiln isineminyaka engu-169 isetshenziswa kusukela yasungulwa futhi isithuthuke kaningi kanye nezinto ezintsha. Olunye uhlobo olusha olunjalo ukungezwa kwepayipi lomoya elingaphansi kwehhanela ukwethula umoya oshisayo owomile (100°C–300°C) egunjini lokomisa ngesikhathi senqubo yokushisa isondo elilodwa. Okunye okusha wukusetshenziswa kwezitini ezibaselwe ngaphakathi, ezasungulwa amaShayina. Ngemva kokuba amalahle echotshoziwe, afakwa ezintweni ezingavuthiwe ngokwenani elidingekayo le-calorific (cishe i-1240 kcal/kg yezinto ezingavuthiwe ezidingekayo ukuze kukhuliswe izinga lokushisa ngo-1 ° C, elilingana no-0.3 kcal). Umshini wokuphakela wemboni yezitini we-“Wanda” ungaxuba amalahle nezinto ezingavuthiwe ngezilinganiso ezifanele. I-mixer ihlanganisa kahle impushana yamalahle nezinto ezingavuthiwe, iqinisekisa ukuthi ukuchezuka kwenani le-calorific kulawulwa ngaphakathi kuka-±200 kJ/kg. Ukwengeza, ukulawulwa kwezinga lokushisa kanye nezinhlelo ze-PLC zifakwe ukuze kulungiswe ngokuzenzakalelayo izinga lokugeleza kwe-damper yomoya kanye nezinga lokudla kwamalahle. Lokhu kuthuthukisa izinga lokuzenzakalela, kuqinisekisa kangcono izimiso ezintathu zokuzinza zokusebenza kweziko likaHoffman: “umfutho womoya ozinzile, izinga lokushisa elizinzile, nokunyakaza kwelangabi okuzinzile.” Ukusebenza okuvamile kudinga ukulungiswa okuguquguqukayo okusekelwe ezimweni ezingaphakathi kweziko, futhi ukusebenza ngokucophelela kungaveza izitini eziqediwe ezifanelekayo.

Isikhathi sokuthumela: Jun-21-2025