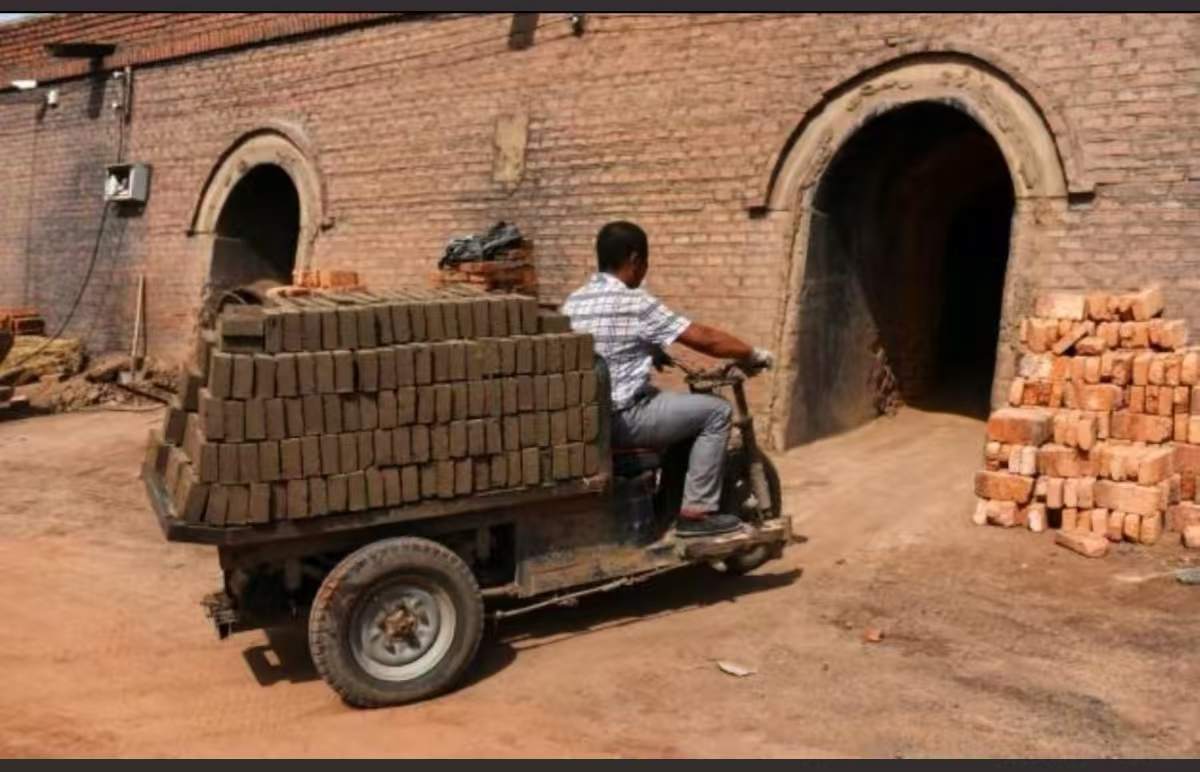

I-Hoffman kiln (eyaziwa ngokuba sisitofu samavili eTshayina) luhlobo lweziko elaqanjwa yinjineli yaseJamani uGustav Hoffman ngo-1856 ukuze kuqhutyekwe nokudubula izitena neethayile. Isakhiwo esiphambili siquka itonela ejikelezayo evaliweyo, ngokuqhelekileyo eyakhiwe ngezitena ezivuthayo. Ukuququzelela imveliso, iingcango ze-ontini ezininzi ezilinganayo zifakwe kwiindonga ze-onti. Umjikelo wokudubula omnye (umlilo omnye) ufuna iingcango ezili-18. Ukuphucula iimeko zokusebenza kunye nokuvumela izitena ezigqityiweyo ixesha elingakumbi lokupholisa, kwakhiwa izitofu ezineengcango ezingama-22 okanye ezingama-24, kwaza kwakhiwa nezitofu ezinomlilo ezimbini ezineengcango ezingama-36. Ngokulawula i-dampers yomoya, i-firehead inokukhokelwa ukuba ihambe, ivumela ukuveliswa okuqhubekayo. Njengodidi lweziko lobunjineli bobushushu, ihonti yeHoffman ikwahlulwe yangakwindawo yokufudumeza, ukudubula kunye neyokupholisa. Noko ke, ngokungafaniyo nezitofu zetonela, apho izitena ezivaliweyo zibekwe kwiimoto ezihambayo, iziko likaHoffman lisebenza ngomgaqo “wokuhamba okungenanto, umlilo uhlala uhleli.” Iindawo ezintathu zokusebenza—ukufudumeza kwangaphambili, ukudubula nokupholisa—zihlala zimi, ngoxa izitena ezivaliweyo zityhutyha imimandla emithathu ukuze kugqitywe inkqubo yokudubula. Iziko likaHoffman lisebenza ngokwahlukileyo: izitena ezivaliweyo zipakishwe ngaphakathi kwiziko kwaye zihlala zimi, ngelixa i-firehead ikhokelwa zizidambisi zomoya ukuze zihambe, zilandela umgaqo othi "ukuhamba komlilo, iindawo ezingenanto zihlala zingashukumi." Ke ngoko, ukufudumeza, ukudubula, kunye neendawo zokupholisa kwihonti yeHoffman ngokuqhubekayo zitshintsha izikhundla njengoko intloko yomlilo ihamba. Indawo ephambi kwedangatye yeyokufudumala, idangatye ngokwalo lelokudubula, kwaye indawo esemva kwedangatye yeyokupholisa. Umgaqo wokusebenza ubandakanya ukulungiswa kwe-damper yomoya ukukhokela ilangatye ukutshisa ngokulandelelana izitena ezifakwe ngaphakathi kwe-oven.

I. Iinkqubo zokuSebenza:

Ukulungiselela kwangaphambili ukutshisa: izinto zokutshisa ezifana neenkuni kunye namalahle. Ukuba usebenzisa izitena zokutsha zangaphakathi, malunga ne-1,100-1,600 kcal / kg yobushushu iyadingeka ukutshisa ikhilogram enye yezinto eziluhlaza ukuya kwi-800-950 ° C. Izitena zokutshisa zingaba zide kancinci, kunye nomxholo womswakama we-≤6%. Izitena ezifanelekileyo zifanele zipakishwe kwiingcango ezintathu okanye ezine zeziko. Ukupakishwa kwezitena kulandela umgaqo othi "qina phezulu kwaye ukhululeke emazantsi, uqine emacaleni kwaye ukhululeke phakathi." Shiya umjelo womlilo oyi-15-20 cm phakathi kwezitena. Imisebenzi yokutshisa yenziwe kakuhle kumacandelo athe tye, ngoko ke isitovu kufuneka sakhiwe emva kokugoba, kumnyango wesibini okanye wesithathu weziko. Isitovu somlilo sinegumbi leziko kunye nezibuko lokususa uthuthu. Imingxuma yokuxheshisela amalahle kunye neendonga ezingangeni moya kwimijelo yomlilo kufuneka ivalwe ukuthintela ukungena komoya obandayo.

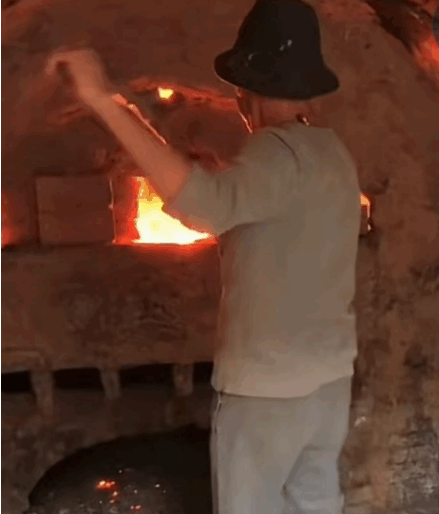

Umlilo kunye nokufudumeza: Phambi kokuba uvuthe, jonga umzimba we-oven kunye nezidambisi-moya ezivuzayo. Vula ifeni kwaye uyilungelelanise ukwenza uxinzelelo oluncinci olubi kwisitovu sokutshisa. Lungisa iinkuni kunye namalahle kwibhokisi yomlilo ukulawula izinga lokufudumeza. Sebenzisa umlilo omncinci ukubhaka iiyure ezingama-24-48, womisa izitena ezivaliweyo ngelixa ususa umswakama kwi-oven. Emva koko, ukwandisa kancinci ukuhamba komoya ukukhawulezisa izinga lokufudumeza. Iindidi ezahlukeneyo zamalahle zineendawo ezahlukeneyo zokutshisa: amalahle amdaka kwi-300-400 ° C, amalahle e-bituminous kwi-400-550 ° C, kunye ne-anthracite kwi-550-700 ° C. Xa izinga lokushisa lifikelela kuma-400 ° C, amalahle ngaphakathi kwezitena aqala ukutshisa, kwaye isitena ngasinye siba ngumthombo wokushisa njengebhola yamalahle. Emva kokuba izitena ziqala ukutshisa, ukuhamba komoya kunokunyuswa ngakumbi ukufikelela kwiqondo lokushisa eliqhelekileyo lokudubula. Xa ubushushu be-kiln bufikelela kwi-600 ° C, i-damper yomoya inokulungiswa ukuze iqondise ilangatye kwigumbi elilandelayo, ligqibe inkqubo yokutshisa.

I-Kiln operation: I-hoffman kiln isetyenziselwa ukutshisa izitena zodongwe, kunye nesantya sokudubula kumagumbi angama-4-6 ngosuku. Ekubeni i-firehead ihlala ihamba, umsebenzi wegumbi le-kiln ngalinye litshintsha ngokuqhubekayo. Xa phambi kwentloko yomlilo, umsebenzi ngummandla wokushisa, kunye namaqondo okushisa angaphantsi kwe-600 ° C, i-air damper ngokuqhelekileyo ivulekile kwi-60-70%, kunye noxinzelelo olubi oluvela kwi--20 ukuya kwi-50 Pa. Ngoxa ususa umswakama, kufuneka kuthathwe amanyathelo angqongqo ukukhusela izitena ezivaliweyo. Ummandla weqondo lokushisa phakathi kwe-600 ° C kunye ne-1050 ° C yindawo yokudubula, apho izitena ezivaliweyo zenza utshintsho. Ngaphantsi kwamaqondo okushisa aphezulu, udongwe luhamba notshintsho lomzimba kunye neekhemikhali, luguqulela kwizitena ezigqityiweyo kunye neempawu ze-ceramic. Ukuba ukushisa kokudubula akufikelelwanga ngenxa yokungabikho kwepetroli eyaneleyo, i-fuel kufuneka ifakwe kwiibhetshi (i-powder yamalahle ≤2 kg emngxunyeni ngamnye), ukuqinisekisa ukunikezelwa kwe-oksijini eyaneleyo (≥5%) yokutshisa, kunye noxinzelelo lwe-kiln olugcinwe kuxinzelelo oluncinci olubi (-5 ukuya -10 Pa). Gcina iqondo lokushisa eliphezulu rhoqo kwiiyure ezi-4-6 ukuze uvutha ngokupheleleyo izitena ezivaliweyo. Emva kokudlula kwindawo yokudubula, izitena ezingenanto ziguqulwa zibe zizitena ezigqityiweyo. Imingxuma yokondla amalahle ivalwa ke, kwaye izitena zingena kwindawo yokugquma kunye nendawo yokupholisa. Izinga lokupholisa akufuneki lidlule kwi-50°C/h ukuthintela ukuqhekeka ngenxa yokuphola ngokukhawuleza. Xa iqondo lokushisa liwela ngaphantsi kwe-200 ° C, umnyango we-oven ungavulwa kufuphi, kwaye emva kokungena komoya kunye nokupholisa, izitena ezigqityiweyo zisuswe kwiziko, zigqibe inkqubo yokudubula.

II. Amanqaku abalulekileyo

Ukupakishwa kwezitena: "Iinxalenye ezintathu ezidubulayo, iinxalenye ezisixhenxe zipakishwe." Kwinkqubo yokudubula, ukupakishwa kwezitena kubalulekile. Kubalulekile ukufezekisa "ubuninzi obunengqiqo," ukufumana ibhalansi efanelekileyo phakathi kwenani lezitena kunye nezikhewu phakathi kwazo. Ngokwemigangatho yelizwe laseTshayina, ukuxinana okufanelekileyo kwezitena ngamaqhekeza angama-260 nge-cubic meter nganye. Ukupakishwa kwezitena kufuneka kuhambelane nemigaqo ethi "dense phezulu, incinci phantsi," "ixinene emacaleni, incinci embindini," kwaye "ushiye indawo yokuhamba komoya," ngelixa uphepha ukungalingani apho umphezulu unzima kwaye umzantsi ulula. Umbhobho womoya onqamlekileyo kufuneka uhambelane ne-exhaust vent, kunye nobubanzi be-15-20 cm. Ukuphambuka okuthe nkqo kwemfumba yezitena akufanele kudlule i-2%, kwaye amanyathelo angqongqo kufuneka athathwe ukukhusela imfumba ekuweni.

Ulawulo lobushushu: Indawo yokufudumeza kwangaphambili kufuneka ifudunyezwe kancinane; ukunyuka kwamaqondo obushushu okukhawulezayo akuvumelekanga ngokungqongqo (ukunyuka kobushushu okukhawulezayo kunokubangela ukuba umswakama ubaleke kwaye uqhekeke izitena ezingenanto). Ngexesha le-quartz metamorphic phase, ubushushu kufuneka bugcinwe buzinzile. Ukuba ubushushu buwela ngaphantsi kobushushu obufunekayo kunye namalahle kufuneka afakwe ngaphandle, ukongezwa kwamalahle agxininisiweyo akuvumelekanga (ukuthintela ukutshiswa kwendawo). Amalahle kufuneka adityaniswe ngemilinganiselo emincinci kaninzi ngomngxuma omnye, kudityaniswe nganye ibe yi-2 kg ngebhetshi nganye, kwaye ibhetshi nganye ishiyana ngemizuzu eli-15 ubuncinci.

Ukhuseleko: Iziko likaHoffman likwayindawo ebiyelweyo. Xa i-carbon monoxide concentration idlula i-24 PPM, abasebenzi kufuneka baphume, kwaye umoya wokuphefumula kufuneka uphuculwe. Emva kokucoca, izitena ezigqityiweyo kufuneka zisuswe ngesandla. Emva kokuvula umnyango we-oven, qala ulinganise umxholo we-oksijini (umxholo we-oxygen> 18%) ngaphambi kokungena emsebenzini.

III. Iimpazamo eziqhelekileyo kunye nokuJonga ingxaki

Imiba eqhelekileyo kwimveliso ye-Hoffman kiln: ukwakhiwa komswakama kwindawo yokufudumeza kwangaphambili kunye nokuwa kwezitena ezimanzi, ngokuyinhloko ngenxa yobuninzi bomswakama kwizitena ezimanzi kunye nokungahambi kakuhle kwamanzi. Indlela yokukhupha amanzi okufuma: sebenzisa izitena ezivaliweyo ezomileyo (ezinobumanzi obushiyekileyo obungaphantsi kwe-6%) kwaye ulungelelanise isidambisi-moya sokunyusa ukuhamba komoya, sinyuse ubushushu bufikelele kwi-120°C. Isantya sokudubula esicothayo: Esidla ngokubizwa ngokuba “ngumlilo awuyi kubamba,” oku kubangelwe kukutsha okungenawo ioksijini. Izisombululo zokungaphumi komoya okunganelanga: Yandisa ukuvuleka kwesidambisi shushu, nyusa isantya sefeni, lungisa izikhewu emzimbeni we-onti, kwaye ucoce inkunkuma eqokelelweyo evela kumbhobho. Isishwankathelo, qinisekisa ukuba ioksijini eyaneleyo inikezelwa kwigumbi lokutsha ukuze kuphunyezwe ukutsha okutyebileyo kweoksijini kunye neemeko zokunyuka kobushushu ngokukhawuleza. Ukuguquka kombala womzimba wezitena (obutyheli) ngenxa yobushushu obunganelanga be-sintering: Isisombululo: Yandisa ngokufanelekileyo isixa samafutha kwaye unyuse ubushushu bokudubula. Izitena ezintsundu ezimnyama zingenza ngenxa yezizathu ezininzi: izongezo ezivuthayo zangaphakathi ezigqithisileyo, ukungabikho kwe-oksijini kwi-oven okudala umoya wokunciphisa (O₂ <3%), okanye izitena ezingagxothi ngokupheleleyo. Izisombululo: Ukunciphisa umthamo wangaphakathi wamafutha, ukwandisa umoya wokutshisa i-oksijini eyaneleyo, kwaye ngokufanelekileyo wandise ubushushu obuphezulu-ubushushu obuhlala ixesha elide ukuqinisekisa ukuba izitena zitshiswa ngokupheleleyo. I-deformation yezitena (i-overfiring) ibangelwa ikakhulu ngamaqondo obushushu aphezulu asekuhlaleni. Izisombululo ziquka ukuvula isidambisi-moya sangaphambili ukuhambisa idangatye phambili kunye nokuvula isiciko somlilo esingasemva ukungenisa umoya opholileyo kwi-oven ukuthoba ubushushu.

I-Hoffman kiln sele isetyenziswa iminyaka eyi-169 ukusukela oko yaqanjwa kwaye iye yaphuculwa ngeendlela ezininzi kunye nezinto ezintsha. Olunye ulutsha olunjalo kukongeza umbhobho womoya ophantsi kwe-kiln ukwazisa umoya owomileyo oshushu (100°C–300°C) kwigumbi lokomisa ngexesha lenkqubo yokutshisa ivili elilodwa. Enye into entsha kukusetyenziswa kwezitena ezibaselwe ngaphakathi, ezaqanjwa ngamaTshayina. Emva kokuba amalahle echotshoziwe, yongezwa kwizinto ezibonakalayo ngokwexabiso le-calorific efunekayo (malunga ne-1240 kcal / kg yezinto ezibonakalayo ezifunekayo ukuphakamisa izinga lokushisa nge-1 ° C, elilingana ne-0.3 kcal). Umatshini wokutyisa womzi-mveliso wezitena “Wanda” unokuxuba amalahle kunye nemathiriyeli ekrwada ngokwemilinganiselo echanekileyo. Umxube udibanisa ngokucokisekileyo umgubo wamalahle kunye nezinto eziluhlaza, uqinisekise ukuba ukuphambuka kwexabiso le-calorific kulawulwa ngaphakathi kwe-± 200 kJ / kg. Ukongeza, ulawulo lobushushu kunye neenkqubo ze-PLC zifakwe ukulungelelanisa ngokuzenzekelayo izinga lokuhamba kwe-damper yomoya kunye nesantya sokutya kwamalahle. Oku kwandisa inqanaba lokuzisebenzela, ukuqinisekisa ngcono imigaqo emithathu yokuzinza ye-Hoffman kiln operation: "uxinzelelo lomoya oluzinzileyo, ubushushu obuzinzileyo, kunye nentshukumo ezinzileyo yedangatye." Ukusebenza okuqhelekileyo kufuna uhlengahlengiso oluguquguqukayo olusekelwe kwiimeko ezingaphakathi kwe-oven, kwaye ukusebenza ngokucophelela kunokuvelisa izitena ezigqityiweyo ezifanelekileyo.

Ixesha lokuposa: Jun-21-2025