I. Kev Taw Qhia:

II. Qauv:

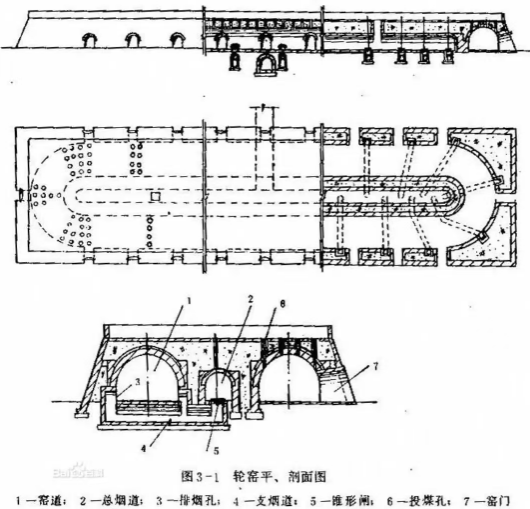

Tom qab cov cib tau muab tso rau hauv lub qhov cub chamber, cov ntawv thaiv yuav tsum tau muab tso rau kom kaw lub chamber ntawm tus kheej. Thaum qhov hluav taws kub qhov chaw yuav tsum tau txav mus, lub damper ntawm lub chamber yog qhib los tsim qhov tsis zoo siab sab hauv, uas rub lub nplaim taws rau hauv lub chamber thiab hlawv cov ntawv thaiv. Hauv cov xwm txheej tshwj xeeb, qhov hluav taws kub hnyiab tuaj yeem siv los rhuav cov ntawv thaiv ntawm lub chamber dhau los. Txhua lub sij hawm qhov hluav taws kub txav mus rau lub chamber tshiab, cov chav tom ntej nkag mus rau theem tom ntej hauv ib ntus. Feem ntau, thaum lub damper nyuam qhuav qhib, lub chamber nkag mus rau hauv preheating thiab kub-nce theem; chambers 2-3 lub qhov rooj deb nkag mus rau theem siab kub tua hluav taws; Chambers 3-4 lub qhov rooj deb nkag mus rau lub rwb thaiv tsev thiab cua txias theem, thiab lwm yam. Txhua chamber tsis tu ncua hloov nws lub luag hauj lwm, tsim ib tug nruam cyclic ntau lawm nrog ib tug tsiv nplaim taws pem hauv ntej. Cov nplaim taws mus nrawm yog cuam tshuam los ntawm huab cua siab, huab cua ntim, thiab roj calorific nqi. Tsis tas li ntawd, nws txawv nrog cov ntaub ntawv cib (4-6 meters ib teev rau shale cib, 3-5 meters ib teev rau av nplaum cib). Yog li ntawd, qhov hluav taws xob ceev thiab cov zis tuaj yeem hloov kho los ntawm kev tswj cov cua siab thiab ntim ntawm cov dampers thiab kho cov khoom siv roj. Cov ntsiab lus noo noo ntawm cib kuj tseem cuam tshuam ncaj qha rau cov nplaim taws mus rau qhov nrawm: 1% txo cov dej noo tuaj yeem ua rau kom nrawm li 10 feeb. Lub sealing thiab rwb thaiv tsev kev ua tau zoo ntawm qhov cub ncaj qha cuam tshuam rau kev siv roj thiab cov khoom siv cib tiav.

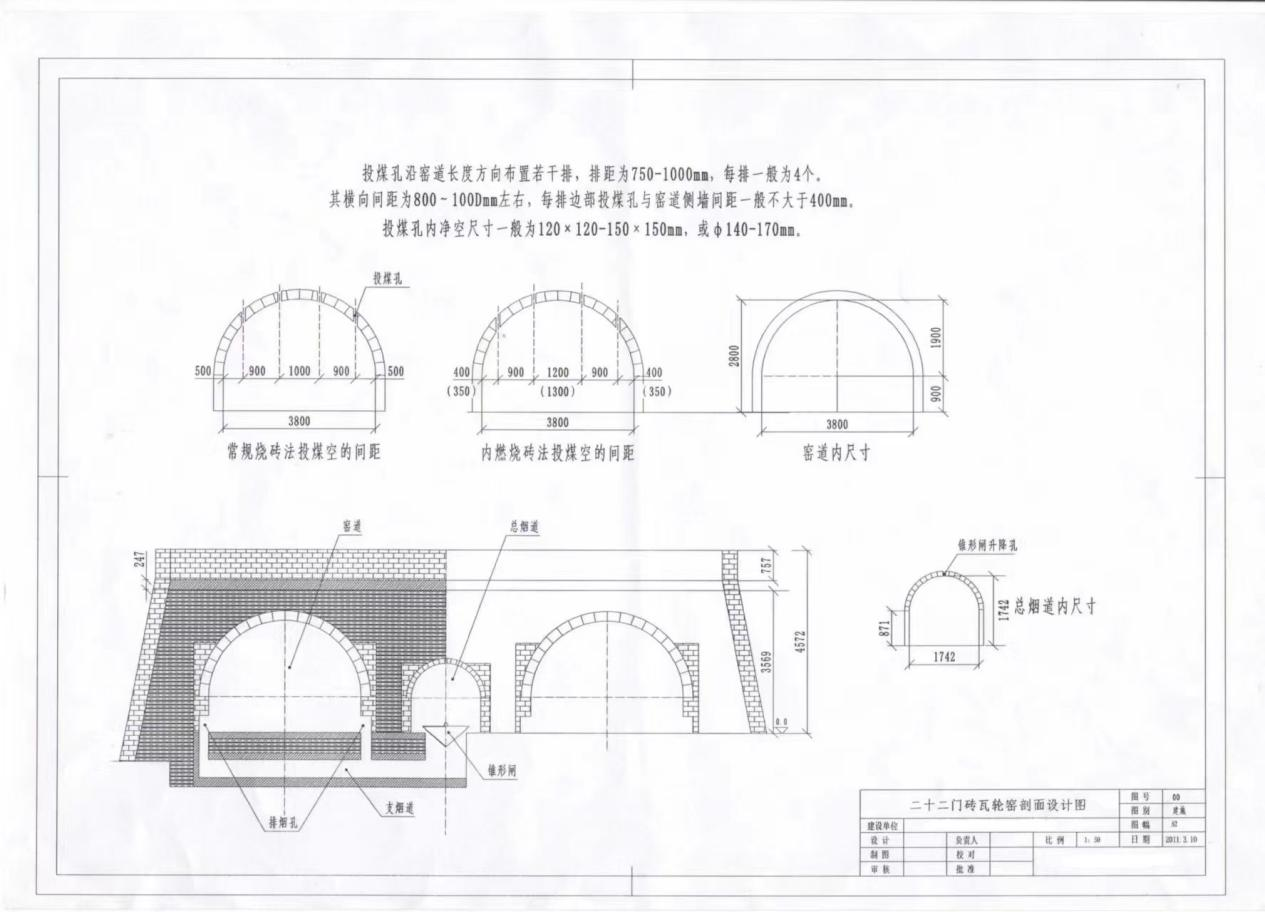

Ua ntej, raws li qhov yuav tsum tau ua, txiav txim siab qhov dav sab hauv ntawm lub kiln. Txawv sab hauv dav xav tau cov huab cua sib txawv. Raws li qhov xav tau huab cua siab thiab ntim, txiav txim siab qhov tshwj xeeb thiab qhov ntau thiab tsawg ntawm lub qhov cub cua nkag, flues, dampers, cov kav dej, thiab cov kav cua loj, thiab suav tag nrho qhov dav ntawm qhov cub. Tom qab ntawd, txiav txim siab cov roj rau cib tua hluav taws-cov roj sib txawv yuav tsum muaj txoj hauv kev sib txawv. Rau cov pa roj carbon monoxide, cov haujlwm rau cov burners yuav tsum tau pre-reserved; rau cov roj hnyav (siv tom qab cua sov), cov haujlwm nozzle yuav tsum tau tshwj tseg. Txawm tias cov thee thiab ntoo (sawdust, nplej husks, txiv laum huab xeeb, thiab lwm yam khoom siv hluav taws xob nrog cov nqi hluav taws xob), cov txheej txheem sib txawv: cov thee yog crushed, yog li cov coal pub qhov yuav me dua; rau kev pub ntoo yooj yim, lub qhov yuav tsum loj dua. Tom qab tsim raws li cov ntaub ntawv ntawm txhua lub kiln tivthaiv, tsim lub kiln siv kos duab kos duab.

III. Kev tsim kho:

① Geological daim ntawv ntsuam xyuas: Paub qhov tob ntawm cov dej hauv av thiab cov av muaj peev xwm (yuav tsum yog ≥150kPa). Rau cov hauv paus mos, siv cov kev hloov pauv (rubble foundation, pawg hauv paus, lossis compacted 3: 7 txiv qaub-av).

② Tom qab kev kho lub hauv paus, tsim lub qhov cub hluav taws xob ua ntej thiab siv cov kev ntsuas dej tsis zoo thiab cov dej tsis zoo: 抹 20mm tuab cov dej khib nyiab txheej, tom qab ntawd ua cov dej tsis zoo.

③ Lub hauv paus kiln siv lub pob zeb ua pob zeb ua kom muaj zog, nrog φ14 steel tuav khi rau hauv 200mm bidirectional daim phiaj. Qhov dav yog raws li kev tsim qauv, thiab lub thickness yog kwv yees li 0.3-0.5 meters.

④ Cov pob qij txha nthuav dav: Npaj ib qho kev sib koom ua ke (30mm dav) rau txhua 4-5 chav, ntim nrog asphalted hemp rau sealing waterproof.

Kiln Lub Cev Kev Tsim Kho:

① Kev npaj cov ntaub ntawv: Tom qab lub hauv paus tiav, theem ntawm qhov chaw thiab npaj cov ntaub ntawv. Cov ntaub ntawv Kiln: Ob qhov kawg ntawm Hoffman kiln yog semicircular; Cov cib tshwj xeeb (cov cib trapezoidal, kiv cua zoo li cib) yog siv ntawm qhov khoov. Yog hais tias lub hauv paus kiln yog tsim nrog firebricks, cov av nplaum hluav taws yuav tsum tau, tshwj xeeb tshaj yog rau arch bricks (T38, T39, feem ntau hu ua "blade bricks") siv nyob rau hauv cov huab cua inlets thiab arch tops. Npaj formwork rau sab saum toj ua ntej.

② Kev teeb tsa: Ntawm lub hauv paus kho mob, kos lub qhov cub qhov chaw nruab nrab ua ntej, tom qab ntawd txiav txim siab thiab kos lub qhov cub phab ntsa thiab lub qhov rooj qhov rooj raws li qhov hluav taws xob hauv av thiab cua nkag. Kos rau rau txoj kab ncaj nraim rau lub cev lub cev thiab cov kab arc rau qhov kawg khoov raws li qhov dav hauv net.

③ Masonry: Ua ntej tsim cov hluav taws xob thiab cua nkag, tom qab ntawd tso cov cib hauv qab (yuav tsum tau sib koom ua ke masonry nrog tag nrho cov mortar, tsis muaj kev sib txuas txuas ntxiv, kom ntseeg tau tias kev sib khi thiab tiv thaiv huab cua tawm). Qhov sib lawv liag yog: tsim cov phab ntsa ncaj nraim raws cov kab hauv paus cim, hloov mus rau qhov khoov, uas yog tsim nrog cov pob zeb trapezoidal (tso cai yuam kev ≤3mm). Raws li kev tsim qauv, tsim cov phab ntsa sib txuas ntawm cov phab ntsa sab hauv thiab sab nrauv thiab sau nrog cov ntaub ntawv rwb thaiv tsev. Thaum cov phab ntsa ncaj nraim ua rau ib qhov siab, nteg lub kaum sab xis ntawm lub cib (60 °-75 °) kom pib tsim lub koov saum toj. Muab cov arch formwork (tso cai arc sib txawv ≤3mm) thiab tsim lub arch top symmetrically ntawm ob sab mus rau qhov chaw. Siv arch bricks (T38, T39) rau lub koov saum; yog siv cov bricks zoo tib yam, xyuas kom ze nrog cov formwork. Thaum tsim lub 3-6 cib kawg ntawm txhua lub nplhaib, siv lub nplhaib-zoo li tus xauv cib (thickness txawv 10-15mm) thiab rauj lawv nruj nrog rauj roj hmab. Reservation ports thiab thee feeding ports on the arch top as per design requirements.

IV. Kev Tswj Xyuas Zoo:

b. Flatness: Kos nrog 2-meter straightedge; tso cai tsis sib xws ≤ 3mm.

c. Sealing: Tom qab qhov cub masonry ua tiav, ua qhov ntsuas qhov tsis zoo (-50Pa); leakage tus nqi ≤0.5m³ / h·m².

Post lub sij hawm: Aug-05-2025