Cov hauv qab no yog cov ntsiab lus ntawm qhov sib txawv, kev tsim cov txheej txheem, daim ntawv thov scenarios, qhov zoo thiab qhov tsis zoo ntawm sintered cib, cement block bricks (concrete blocks) thiab ua npuas ncauj cib (feem ntau yog xa mus rau aerated qhob blocks lossis ua npuas ncauj ua npuas ncauj), uas yooj yim rau kev xaiv tsim nyog hauv kev tsim kho:

I. Core Difference Sib piv

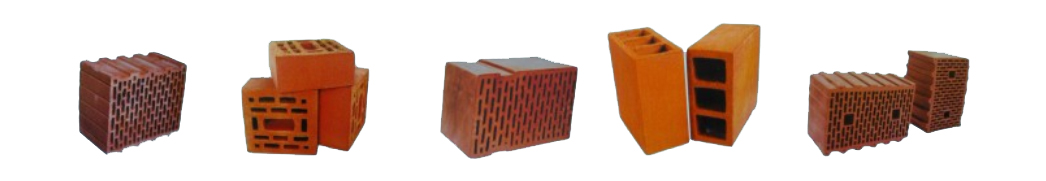

| Qhov project | Sintered Cib | Cement Block Cib (Concrete Block) | Ua Npuas Ncauj Cib (Aerated / Foam Concrete Block) |

|---|---|---|---|

| Cov ntaub ntawv tseem ceeb | Av nplaum, shale, ya tshauv, thiab lwm yam (yuav tsum tau tua) | Cement, xuab zeb thiab gravel, aggregate (crushed pob zeb / slag, thiab lwm yam) | Cement, ya tshauv, foaming agent (xws li txhuas hmoov), dej |

| Cov yam ntxwv ntawm cov khoom tiav | Nthuav, loj tus kheej hnyav, siab zog | Hollow los yog khoom, nruab nrab mus rau siab zog | Porous thiab hnav, tsis tshua muaj ntom (kwv yees li 300-800kg / m³), zoo thermal rwb thaiv tsev thiab suab rwb thaiv tsev |

| Hom Specifications | Txheem cib: 240 × 115 × 53mm (khoom) | Feem ntau: 390 × 190 × 190mm (feem ntau hollow) | Feem ntau: 600 × 200 × 200mm (hollow, ntxeem tau qauv) |

II.Qhov sib txawv ntawm cov txheej txheem tsim khoom

1.Sintered cib

●Txheej txheem:

Raw khoom soj ntsuam → Raw khoom crushing → Sib tov thiab nplawm → 坯体成型 → ziab → High-temperature sintering (800-1050 ℃) → Txias.

●Txheej txheem tseem ceeb:

Los ntawm kev tua hluav taws, kev hloov pauv ntawm lub cev thiab tshuaj lom neeg (melting, crystallization) tshwm sim hauv cov av nplaum los tsim cov qauv uas muaj zog heev.

●Yam ntxwv:

Cov av nplaum muaj ntau. Kev siv cov pov tseg xws li thee mine slag thiab ore hnav khaub ncaws tailings tuaj yeem txo cov pa phem. Nws tuaj yeem yog industrialized rau ntau lawm. Cov cib tiav lawm muaj lub zog siab, zoo stability thiab durability.

2.Cement Block Cib (Concrete Blocks)

●Txheej txheem:

Cement + Xuab zeb thiab gravel aggregate + Dej sib tov thiab nplawm → Moulding los ntawm kev vibration / nias rau hauv pwm → Natural curing lossis steam curing (7-28 hnub).

●Txheej txheem tseem ceeb:

Los ntawm cov tshuaj tiv thaiv hydration ntawm cov cement, cov khoom thaiv (load-bearing) lossis hollow blocks (non-load-bearing) tuaj yeem tsim. Qee qhov sib xyaw ua ke (xws li slag, ceramsite) tau ntxiv los txo qhov hnyav ntawm tus kheej.

●Yam ntxwv:

Cov txheej txheem yog yooj yim thiab lub voj voog yog luv. Nws tuaj yeem ua rau ntawm qhov loj me, thiab lub zog tuaj yeem hloov kho (tswj los ntawm qhov sib tov sib xyaw). Txawm li cas los xij, qhov hnyav ntawm tus kheej yog ntau dua li ntawm cov pob zeb ua npuas ncauj. Tus nqi ntawm cov cib tiav yog siab thiab cov khoom tso tawm raug txwv, uas yog tsim rau cov khoom me me.

3.Ua Npuas Ncauj Cib (Aerated / Foam Concrete Blocks)

●Txheej txheem:

Cov ntaub ntawv raw (cement, ya tshauv, xuab zeb) + Foaming agent (hydrogen yog generated thaum txhuas hmoov reacts nrog dej mus ua npuas ncauj) mixing → Pouring thiab foaming → Static chaw thiab kho → Txiav thiab sib sau → Autoclave curing (180-200 ℃, 8-12 teev).

●Txheej txheem tseem ceeb:

Tus neeg sawv cev foaming yog siv los tsim cov pores, thiab cov qauv siv lead ua ntxeem tau (xws li tobermorite) yog tsim los ntawm autoclave curing, uas yog hnav thiab muaj thermal rwb thaiv tsev.

●Yam ntxwv:

Lub degree ntawm automation yog siab thiab txuag hluav taws xob (lub zog noj ntawm autoclave curing yog qis dua li ntawm sintering), tab sis qhov yuav tsum tau rau cov raw khoom piv thiab foaming tswj yog siab. Lub zog compressive yog tsawg thiab nws tsis resistant rau khov. Nws tsuas yog siv tau rau hauv cov tsev thav duab thiab sau cov phab ntsa.

III.Daim ntawv thov sib txawv hauv cov phiaj xwm kev tsim kho

1.Sintered cib

●Siv tau Scenarios:

Load-bearing walls of low-rise buildings (xws li cov tsev nyob hauv qab rau pem teb), enclosure phab ntsa, cov tsev nrog ib tug retro style (siv cov tsos ntawm liab cib).

Cov khoom uas yuav tsum tau ua kom ntev (xws li lub hauv paus, sab nraum zoov paving).

●Qhov zoo:

Lub zog siab (MU10-MU30), huab cua zoo thiab tiv thaiv te, ua haujlwm ntev.

Cov txheej txheem ib txwm muaj kev paub tab thiab muaj zog yoog raws (zoo adhesion nrog mortar).

●Qhov tsis zoo:

Nws siv cov khoom siv av nplaum thiab cov txheej txheem tua hluav taws ua rau qee qhov kev ua qias tuaj (tam sim no, ya tshauv / shale sintered cib feem ntau txhawb los hloov cov av nplaum cib).

Loj tus kheej qhov hnyav (kwv yees li 1800kg / m³), ua kom cov khoom thauj khoom.

2.Cement Block Cib

●Siv tau Scenarios:

Load-bearing blocks (khoom / ntxeem tau): Sau cov phab ntsa ntawm cov qauv thav duab, load-bearing phab ntsa ntawm cov tsev qis (qib zog MU5-MU20).

Non-load-bearing hollow blocks: Sab hauv muab faib phab ntsa ntawm cov tsev siab siab (kom txo tus kheej qhov hnyav).

●Qhov zoo:

Lub tshuab ib leeg tso zis tsawg thiab tus nqi siab me ntsis.

Lub zog tuaj yeem hloov kho, cov khoom siv raw tau yooj yim muaj, thiab cov khoom siv tau yooj yim (lub thaiv yog loj, thiab cov masonry efficiency siab).

Kev ua haujlwm zoo, tuaj yeem siv rau hauv qhov chaw ntub dej (xws li chav dej, phab ntsa hauv qab).

●Qhov tsis zoo:

Loj tus kheej hnyav (li 1800kg / m³ rau cov khoom thaiv, txog 1200kg / m³ rau hollow blocks), kev ua haujlwm thermal rwb thaiv tsev dav dav (thickening lossis ntxiv ib txheej thermal rwb thaiv tsev ntxiv).

Kev nqus dej siab, nws yog ib qho tsim nyog rau dej thiab moisten nws ua ntej masonry kom tsis txhob poob dej hauv mortar.

3.Ua Npuas Ncauj Cib (Aerated / Foam Concrete Blocks)

●Siv tau Scenarios:

Cov phab ntsa uas tsis muaj kev thauj khoom: Sab hauv thiab sab nrauv muab faib phab ntsa ntawm cov tsev siab siab (xws li sau cov phab ntsa ntawm cov thav duab), cov tsev uas yuav tsum muaj lub zog txuag hluav taws xob (yuav tsum tau rwb thaiv tsev thermal).

Tsis haum rau: Lub hauv paus, qhov chaw ntub dej (xws li chav dej, hauv qab daus), cov khoom thauj khoom.

●Qhov zoo:

Lub teeb yuag (qhov ceev tsuas yog 1/4 rau 1/3 ntawm cov sintered cib), zoo heev txo cov txheej txheem thauj khoom thiab txuag cov nyiaj ntawm cov pob zeb ntxiv.

Zoo thermal rwb thaiv tsev thiab suab rwb thaiv tsev (lub thermal conductivity yog 0.1-0.2W / (m・K), uas yog 1/5 ntawm sintered cib), ua tau raws li cov qauv kev txuag hluav taws xob.

Kev tsim kho yooj yim: Lub thaiv yog qhov loj (qhov loj me yog li niaj zaus), nws tuaj yeem saws thiab npaj, qhov flatness ntawm phab ntsa yog siab, thiab cov txheej plaster yog txo.

●Qhov tsis zoo:

Tsis tshua muaj zog (lub zog compressive feem ntau yog A3.5-A5.0, tsuas yog haum rau cov khoom tsis-load-bearing), qhov saum npoo yog yooj yim rau kev puas tsuaj, thiab kev sib tsoo yuav tsum zam.

Kev nqus dej muaj zog (tus nqi nqus dej yog 20% -30%), kev sib txuas yuav tsum tau kho; Nws yog ib qho yooj yim rau soften nyob rau hauv ib qho chaw ntub dej, thiab yuav tsum muaj ib txheej dej-pov thawj.

Tsis muaj zog adhesion nrog mortar zoo tib yam, tshwj xeeb nplaum los yog tus neeg saib xyuas interface yuav tsum tau.

IV.Yuav xaiv li cas? Core Reference Factors

●Load-bearing Requirements:

Load-bearing phab ntsa: Muab qhov tseem ceeb rau sintered cib (rau cov tsev siab siab me) los yog cov cement blocks siab (MU10 thiab siab dua).

Cov phab ntsa tsis-load-bearing: Xaiv cov pob zeb ua npuas ncauj (muab qhov tseem ceeb rau kev txuag hluav taws xob) lossis hollow cement blocks (muab qhov tseem ceeb rau tus nqi).

●Thermal rwb thaiv tsev thiab kev txuag hluav taws xob:

Nyob rau hauv cov cheeb tsam txias los yog lub tsev txuag hluav taws xob: Ua npuas ncauj cib (nrog rau cov rwb thaiv tsev thermal), tsis tas yuav tsum muaj txheej txheej thermal rwb thaiv tsev ntxiv; nyob rau lub caij ntuj sov thiab lub caij ntuj no txias, kev xaiv tuaj yeem ua ke nrog kev nyab xeeb.

●Ib puag ncig tej yam kev mob:

Hauv qhov chaw ntub dej (xws li hauv qab daus, chav ua noj thiab chav dej): Tsuas yog sintered cib thiab cement blocks (kev kho dej tsis zoo) tuaj yeem siv, thiab cov cib ua npuas dej (yuav ua rau muaj kev puas tsuaj vim kev nqus dej) yuav tsum zam.

Rau qhov chaw sab nraum zoov: Muab qhov tseem ceeb rau sintered cib (muaj zog tiv thaiv huab cua) los yog cement blocks nrog kev kho saum npoo.

Cov ntsiab lus

●Sintered bricks:Cov tsoos siab-lub zog cib, haum rau cov khoom siv qis-nce load-cov kabmob thiab cov tsev retro, nrog kev ruaj ntseg zoo thiab kav ntev.

●Cement blocks:Kev nqis peev me me, ntau yam khoom siv, haum rau ntau yam kev thauj khoom-cov kabmob / tsis-load-cov kabmob phab ntsa. Vim yog tus nqi siab ntawm cov cement, tus nqi siab me ntsis.

●Ua npuas ncauj cib:Thawj qhov kev xaiv rau lub teeb yuag thiab txuag hluav taws xob, haum rau sab hauv muab faib phab ntsa ntawm cov tsev siab siab thiab cov xwm txheej nrog cov thermal rwb thaiv tsev siabcov kev xav tau, tab sis kev saib xyuas yuav tsum tau them rau cov dej pov thawj thiab kev txwv lub zog.

Raws li cov kev cai tshwj xeeb ntawm qhov project (load-bearing, lub zog-txuag, ib puag ncig, nyiaj txiag), lawv yuav tsum tau siv tsim nyog ua ke. Rau load-bearing, xaiv sintered cib. Rau lub hauv paus, xaiv sintered cib. Rau cov phab ntsa thaiv thiab cov tsev nyob, xaiv sintered cib thiab cement thaiv cib. Rau cov txheej txheem thav duab, xaiv lub teeb ua npuas ncauj cib rau kev faib phab ntsa thiab sau cov phab ntsa.

Post lub sij hawm: May-09-2025