Kiln Hoffman (wanda aka sani da kiln wheel a China) wani nau'in kiln ne da injiniyan Jamus Gustav Hoffman ya ƙirƙira a shekara ta 1856 don ci gaba da harba bulo da tayal. Babban tsarin ya ƙunshi rufaffiyar rami madauwari, yawanci ana gina shi daga bulo da aka kora. Don sauƙaƙe samarwa, ana shigar da ƙofofin kiln da yawa daidai gwargwado akan bangon kiln. Zagayowar harbe-harbe guda ɗaya (fitar wuta ɗaya) tana buƙatar kofofi 18. Don inganta yanayin aiki da ƙyale tubalin da aka gama su sami ƙarin lokaci don yin sanyi, an gina kiln mai kofofi 22 ko 24, an kuma gina murhun wuta biyu masu kofofi 36. Ta hanyar sarrafa dampers na iska, ana iya jagorantar wutar lantarki don motsawa, yana ba da damar ci gaba da samarwa. A matsayin nau'in kiln injiniya na thermal, ana kuma raba kiln Hoffman zuwa preheating, harbe-harbe, da wuraren sanyaya. Duk da haka, sabanin ramin kilns, inda aka sanya bulo na bulo a kan motocin kiln da ke motsawa, Hoffman kiln yana aiki bisa ka'idar "marar motsi, wutar ta tsaya har yanzu." Wuraren aiki guda uku - preheating, harbe-harbe, da sanyaya - sun kasance a tsaye, yayin da bulo na bulo suna motsawa ta yankuna uku don kammala aikin harbe-harbe. Hoffman kiln yana aiki daban-daban: bulo blanks an tattara su a cikin kiln kuma sun kasance a tsaye, yayin da wutar lantarki ke jagoranta ta hanyar dampers don motsawa, bin ka'idar "wuta tana motsawa, blanks sun tsaya har yanzu." Saboda haka, preheating, harbe-harbe, da sanyaya yankuna a cikin Hoffman kiln suna ci gaba da canza wurare yayin da wutar ke motsawa. Wurin da ke gaban harshen wuta ne don yin zafi, wutar da kanta ita ce ta harbe-harbe, kuma wurin da ke bayan wutar don sanyaya. Ƙa'idar aiki ta ƙunshi daidaita damper ɗin iska don jagorantar harshen wuta zuwa jere da wuta da tubalin da aka jera a cikin murhu.

I. Hanyoyin Aiki:

Shirye-shiryen riga-kafi: kayan wuta kamar itacen wuta da kwal. Idan ana amfani da tubalin konewa na ciki, ana buƙatar kusan 1,100-1,600 kcal/kg na zafi don ƙone kilo ɗaya na albarkatun kasa zuwa 800-950 ° C. Bulogin ƙonewa na iya zama ɗan tsayi kaɗan, tare da abun ciki na danshi na ≤6%. Ya kamata a tara ƙwararrun tubali a cikin ƙofofin wuta uku ko huɗu. Tari tubali yana bin ka'idar "tsatse a sama da sako-sako a kasa, mai matsewa a gefuna da sako-sako a tsakiya." Bar tashar wuta ta 15-20 cm tsakanin tarin bulo. Ayyukan ƙonewa sun fi dacewa a kan sassan madaidaiciya, don haka ya kamata a gina murhun wuta bayan lanƙwasa, a ƙofar kiln na biyu ko na uku. Murhun wuta yana da ɗakin murhu da tashar cire toka. Dole ne a rufe ramukan ciyar da kwal da ganuwar da ke hana iska a cikin tashoshi na wuta don hana iska mai sanyi shiga.

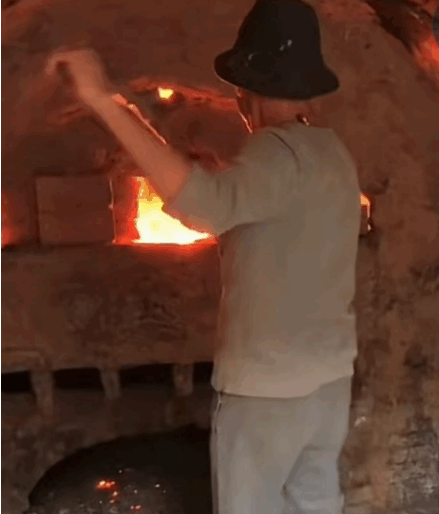

Kunnawa da dumama: Kafin kunnawa, bincika jikin kiln da dampers na iska don ɗigogi. Kunna fanka kuma daidaita shi don haifar da ɗan matsi mara kyau a murhun wuta. Kunna itace da gawayi akan akwatin wuta don sarrafa yawan dumama. Yi amfani da ƙaramin wuta don yin gasa na tsawon sa'o'i 24-48, bushewa bulo da bulo yayin cire danshi daga kiln. Sa'an nan, dan kadan ƙara yawan iska don hanzarta yawan dumama. Nau'o'in kwal daban-daban suna da maki daban-daban na kunna wuta: gawayi mai launin ruwan kasa a 300-400 ° C, kwal mai bituminous a 400-550C, da anthracite a 550-700C. Lokacin da zafin jiki ya kai sama da 400 ° C, kwal ɗin da ke cikin tubalin ya fara ƙonewa, kuma kowane bulo ya zama tushen zafi kamar ƙwallon wuta. Da zarar tubalin ya fara ƙonewa, za a iya ƙara yawan iska don isa yanayin zafin wuta na al'ada. Lokacin da zafin jiki na kiln ya kai 600 ° C, ana iya daidaita damper na iska don tura harshen wuta zuwa ɗakin da ke gaba, yana kammala aikin kunnawa.

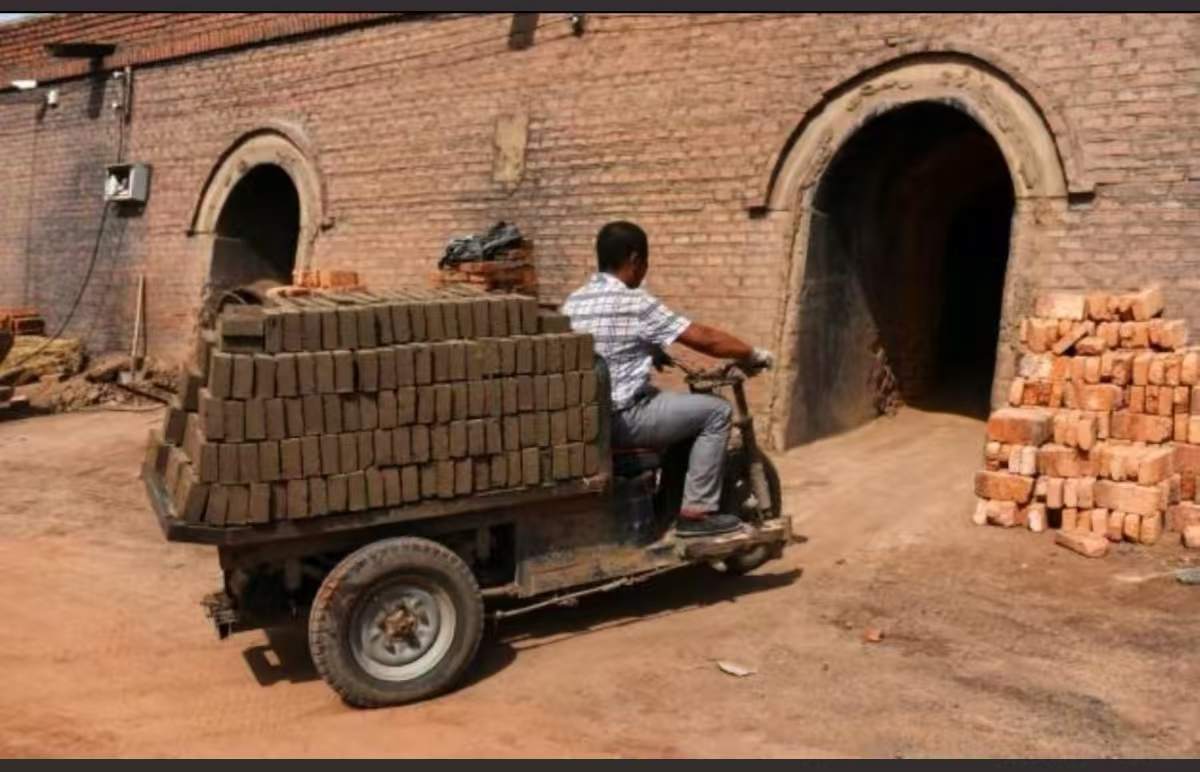

Aikin kiln: Ana amfani da kiln Hoffman don ƙone tubalin yumbu, tare da yawan harbe-harbe a ɗakunan kiln 4-6 kowace rana. Tun da kullun wuta yana motsawa akai-akai, aikin kowane ɗakin kiln shima yana canzawa akai-akai. Lokacin da ke gaban wutar lantarki, aikin shine yankin preheating, tare da yanayin zafi da ke ƙasa da 600 ° C, damper na iska yana buɗewa kullum a 60-70%, kuma mummunan matsa lamba daga -20 zuwa 50 Pa. Yayin da ake cire danshi, dole ne a dauki matakan kariya don hana bulo blanks daga fashewa. Yankin zafin jiki tsakanin 600°C da 1050°C shine yankin harbe-harbe, inda bulo ke samun canji. A karkashin yanayin zafi mai zafi, yumbu yana fuskantar canje-canje na jiki da na sinadarai, yana canzawa zuwa tubalin da aka gama tare da kayan yumbu. Idan yawan zafin jiki na harbe-harbe ba a kai ba saboda rashin isasshen man fetur, dole ne a ƙara man fetur a cikin batches (kwal foda ≤2 kg kowane rami a kowane lokaci), tabbatar da isasshen iskar oxygen (≥5%) don konewa, tare da matsa lamba na kiln da aka kiyaye a dan kadan matsa lamba (-5 zuwa -10 Pa). Kula da yawan zafin jiki na tsawon sa'o'i 4-6 don cikakken ƙone bulo ɗin. Bayan wucewa ta yankin harbe-harbe, bulo na bulo yana canzawa zuwa tubalin da aka gama. Ana rufe ramukan ciyar da gawayi, kuma tubalin sun shiga yankin da aka rufe da sanyaya. Adadin sanyaya dole ne ya wuce 50°C/h don hana fashewa saboda saurin sanyaya. Lokacin da zafin jiki ya faɗi ƙasa da 200 ° C, ana iya buɗe ƙofar kiln a kusa, kuma bayan samun iska da sanyaya, ana cire tubalin da aka gama daga murhun, suna kammala aikin harbi.

II. Muhimman Bayanan kula

Takardun tubali: "Yana harbe-harbe sassa uku, sassa bakwai tara." A cikin tsarin harbe-harbe, toshe bulo yana da mahimmanci. Yana da mahimmanci don cimma "yawanci mai ma'ana," gano ma'auni mafi kyaun tsakanin adadin tubalin da rata tsakanin su. Bisa ka'idojin kasar Sin, madaidaicin yawan adadin tubali shine guda 260 a kowace mita kubik. Dole ne tukwane tubali ya bi ka'idodin "mai yawa a sama, maras kyau a ƙasa," "mai yawa a gefe, ƙananan a tsakiya," da "bar sararin samaniya don iska," yayin da yake guje wa rashin daidaituwa inda saman yana da nauyi kuma ƙasa yana da haske. Bututun iska a kwance ya kamata ya daidaita tare da iska mai shayewa, tare da nisa na 15-20 cm. Matsakaicin tulin bulo na tsaye bai kamata ya wuce 2% ba, kuma dole ne a ɗauki tsauraran matakai don hana tulin daga faɗuwa.

Kula da zafin jiki: Yankin preheating ya kamata a yi zafi a hankali; An haramta haɓaka saurin zafin jiki sosai (ƙarawar zafin jiki mai sauri zai iya haifar da danshi don tserewa da fasa bulo). A lokacin ƙayyadadden lokaci na ma'adini, dole ne a kiyaye zafin jiki a karye. Idan zafin jiki ya faɗi ƙasa da zafin da ake buƙata kuma ana buƙatar ƙara kwal a waje, an hana ƙarar kwal (don hana ƙonewa a cikin gida). Ya kamata a ƙara kwal a cikin ƙananan adadin sau da yawa ta hanyar rami ɗaya, tare da kowane ƙari yana zama kilogiram 2 a kowane tsari, kuma kowane nau'i yana nisa aƙalla mintuna 15.

Tsaro: Hoffman kiln kuma wuri ne da aka rufe. Lokacin da ƙwayar carbon monoxide ya wuce 24 PPM, dole ne ma'aikata su kwashe, kuma dole ne a inganta samun iska. Bayan an gama, dole ne a cire tubalin da aka gama da hannu. Bayan buɗe ƙofar kiln, da farko auna abun cikin oxygen (abincin oxygen> 18%) kafin shiga aiki.

III. Laifi gama gari da magance matsala

Batutuwa gama gari a cikin samar da kiln na Hoffman: haɓakar danshi a cikin yankin da aka rigaya da zafin rana da rugujewar jikakken bulo, da farko saboda yawan danshi a cikin tubalin rigar da ƙarancin magudanar ruwa. Hanyar magudanar danshi: yi amfani da busassun bulo (tare da ragowar abun ciki a ƙasa da 6%) kuma daidaita damper ɗin iska don ƙara yawan iska, haɓaka zafin jiki zuwa kusan 120 ° C. Gudun harbe-harbe a hankali: Wanda aka fi sani da "wuta ba za ta kama ba," wannan yana faruwa da farko saboda konewar karancin iskar oxygen. Magani don rashin isassun iskar iska: Haɓaka buɗaɗɗen damper, haɓaka saurin fan, gyara gibin jikin kiln, da tsaftataccen tarkace daga hayaƙi. A taƙaice, tabbatar da isassun isashshen iskar oxygen zuwa ɗakin konewa don cimma konewar wadataccen iskar oxygen da yanayin hawan zafi mai sauri. Canjin launin tubali (rawaya) saboda rashin isasshen zafin jiki: Magani: Ƙara yawan man fetur daidai da haɓaka zafin wuta. Tubalo masu baƙar fata na iya haifar da dalilai da yawa: ƙari mai yawa na konewa na ciki, ƙarancin iskar oxygen a cikin kiln yana haifar da raguwar yanayi (O₂ <3%), ko tubalin da ba a gama kora ba. Magani: Rage abun ciki na man fetur na ciki, ƙara samun iska don isassun konewar iskar oxygen, da kuma tsawaita tsawon lokacin zafi mai tsayi don tabbatar da cewa tubalin ya cika. Nakasar tubali (overfiring) na faruwa ne da farko saboda yanayin zafi da aka keɓe. Magani sun haɗa da buɗe damper ɗin iska na gaba don matsar da harshen wuta gaba da buɗe murfin wuta na baya don shigar da iska mai sanyi a cikin kiln don rage zafin jiki.

An yi amfani da kiln na Hoffman tsawon shekaru 169 tun lokacin da aka kirkiro shi kuma ya sami gyare-gyare da dama da yawa. Ɗayan irin wannan sabon abu shine ƙari na tashar iska ta ƙasa don shigar da busasshiyar iska mai zafi (100 ° C-300 ° C) a cikin ɗakin bushewa yayin aikin kiln dabaran mai harbi ɗaya. Wata sabuwar dabara ita ce amfani da bulo da aka harba a cikin gida, wadanda Sinawa suka kirkira. Bayan da aka murƙushe kwal, an ƙara shi a cikin kayan da ake buƙata bisa ga ƙimar calorific da ake buƙata (kimanin 1240 kcal / kg na albarkatun kasa ana buƙata don haɓaka zafin jiki ta 1 ° C, daidai da 0.3 kcal). Injin ciyar da bulo na “Wanda” na iya haɗa kwal da albarkatun ƙasa daidai gwargwado. Mai haɗawa sosai yana haɗa foda na kwal tare da albarkatun ƙasa, yana tabbatar da cewa ana sarrafa karkatar da ƙimar calorific a cikin ± 200 kJ/kg. Bugu da ƙari, ana shigar da tsarin kula da zafin jiki da tsarin PLC don daidaita yawan magudanar ruwa ta atomatik da ƙimar ciyarwar kwal. Wannan yana haɓaka matakin aiki da kai, mafi kyawun tabbatar da ƙa'idodin kwanciyar hankali guda uku na aikin Hoffman kiln: "matsalar iska, kwanciyar hankali da zafin jiki, da motsin harshen wuta." Aiki na yau da kullun yana buƙatar gyare-gyare masu sassauƙa dangane da yanayin da ke cikin kiln, kuma aiki mai hankali zai iya samar da ƙwararrun tubalin da aka gama.

Lokacin aikawa: Juni-21-2025