I. Isingeniso:

II. Isakhiwo:

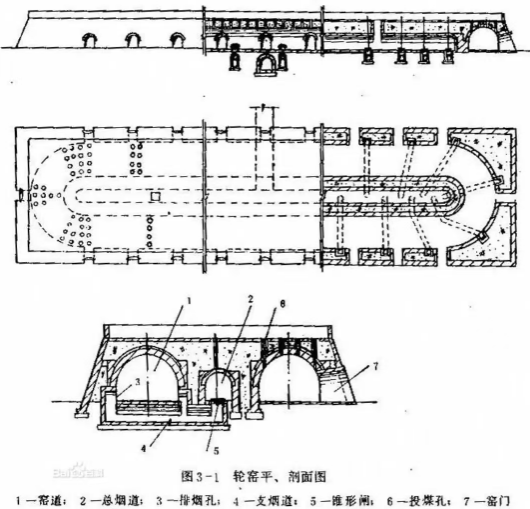

Ngemva kokuba izitini zimbondelene egumbini lomlilo, izithiyo zephepha kufanele zinamathiselwe ukuze kuvalwe igumbi ngalinye. Lapho indawo yomlilo idinga ukunyakaza, i-damper yalelo gumbi iyavuleka ukuze idale ukucindezela okungalungile ngaphakathi, okudonsela i-flame front ekamelweni futhi kushise umgoqo wephepha. Ezimweni ezikhethekile, i-hook yomlilo ingasetshenziswa ukudabula umgoqo wephepha wekamelo langaphambilini. Isikhathi ngasinye lapho indawo yomlilo ithuthela ekamelweni elisha, amakamelo alandelayo angena esigabeni esilandelayo ngokulandelana. Ngokuvamile, lapho i-damper isanda kuvulwa, ikamelo lingena esiteji sokushisa nokushisa; amakamelo 2-3 iminyango ingena esiteji sokudubula esiphezulu; amakamelo 3-4 iminyango away faka ukwahlukanisa kanye esiteji sokupholisa, nokunye. Igumbi ngalinye lishintsha ngokuqhubekayo indima yalo, lakha ukukhiqizwa komjikelezo oqhubekayo onelangabi elinyakazayo. Isivinini sokuhamba kwelangabi sithintwa umfutho womoya, umthamo womoya, kanye nenani likaphethiloli lekhalori. Ukwengeza, kuyahlukahluka ngezinto zokusetshenziswa zezitini (amamitha angu-4-6 ngehora ngezitini ze-shale, amamitha angu-3-5 ngehora ngezitini zobumba). Ngakho-ke, isivinini sokudubula kanye nokuphumayo kungalungiswa ngokulawula ukucindezela komoya kanye nevolumu ngokusebenzisa ama-dampers kanye nokulungisa ukunikezwa kukaphethiloli. Umswakama wezitini ubuye uthinte ngqo isivinini sokuhamba kwelangabi: ukwehla ngo-1% kokuqukethwe komswakama kungakhuphula isivinini cishe ngemizuzu eyi-10. Ukubekwa uphawu nokusebenza kokufakwa kweziko kuthinta ngqo ukusetshenziswa kukaphethiloli kanye nokukhishwa kwezitini eziqediwe.

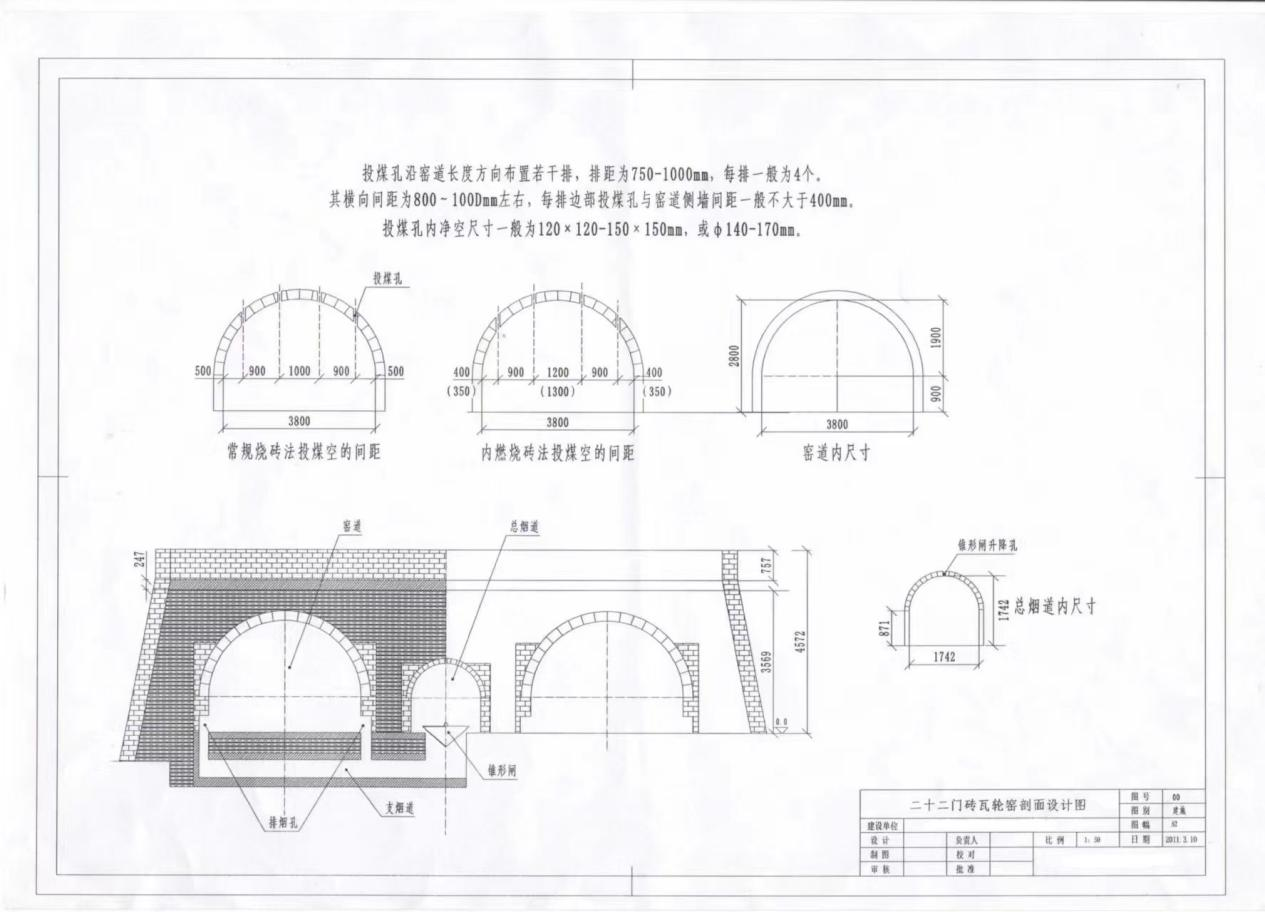

Okokuqala, ngokusekelwe kumfuneko yokukhiphayo, nquma ububanzi bangaphakathi obuphelele behhashi. Ububanzi obuhlukene bangaphakathi budinga amavolumu omoya ahlukene. Ngokusekelwe kumfutho womoya odingekayo kanye nevolumu, nquma ukucaciswa nosayizi bama-inlet, amaflue, ama-dammpers, amapayipi omoya, namapayipi omoya amakhulu, bese ubala ingqikithi yobubanzi behhala. Khona-ke, thola uphethiloli wokudubula izitini-amafutha ahlukene adinga izindlela ezihlukene zokuvutha. Ngegesi yemvelo, izikhundla zezimbawula kufanele zigcinwe kusengaphambili; kumafutha anzima (asetshenziswe ngemva kokushisa), izikhundla ze-nozzle kumele zigcinwe. Ngisho namalahle nezinkuni (i-sawdust, amakhoba elayisi, amagobolondo amakinati, nezinye izinto ezivuthayo ezinenani lokushisa), izindlela ziyahlukahluka: amalahle ayachotshozwa, ngakho imigodi yokuphakela amalahle ingaba mincane; ukuze kube lula ukudla izinkuni, izimbobo kufanele zibe zinkulu ngokufanele. Ngemva kokuklama ngokusekelwe kudatha yengxenye ngayinye yeziko, yakha imidwebo yokwakha yeziko.

III. Inqubo yokwakha:

① Inhlolovo yokwakheka komhlaba: Thola ukujula kongqimba lwamanzi angaphansi komhlaba kanye namandla okuthwala inhlabathi (kudingeka kube ≥150kPa). Ukuze uthole izisekelo ezithambile, sebenzisa izindlela zokushintsha (isisekelo semfucumfucu, isisekelo senqwaba, noma inhlabathi egayiwe ye-lime engu-3:7).

② Ngemva kokwelashwa kwesisekelo, yakha i-kiln flue kuqala bese usebenzisa izinyathelo zokungangeni kwamanzi kanye nezokuvikela umswakama: 抹 ungqimba oluwugqinsi lodaka olungangeni manzi olungama-20mm, bese wenza ukwelashwa okungangeni manzi.

③ Isisekelo se-kiln sisebenzisa i-raft slab kakhonkolo eqinisiwe, enemigoqo yensimbi engu-φ14 eboshwe kugridi ye-bidirectional engu-200mm. Ububanzi buhambisana nezidingo zomklamo ngamunye, futhi ubukhulu bucishe bube ngamamitha angu-0.3-0.5.

④ Amalunga okunweba: Hlela ijoyinti elilodwa lokunweba (30mm ububanzi) kuwo wonke amagumbi angu-4-5, agcwaliswe nge-asphalted hemp ukuze kuvalwe amanzi.

Ukwakhiwa komzimba we-Kiln:

① Ukulungiswa kwezinto: Ngemva kokuqedwa kwesisekelo, linganisa indawo bese ulungisa izinto zokwakha. Izinto zokushisela umlilo: Iziphetho ezimbili zehhavini likaHoffman ziyi-semicircular; Izitini ezimise okukhethekile (izitini ze-trapezoidal, izitini ezimise okwefeni) zisetshenziswa ekugobeni. Uma umzimba womlilo wangaphakathi wakhiwe ngezitini zomlilo, ubumba lomlilo luyadingeka, ikakhulukazi izitini ze-arch (T38, T39, ezivame ukubizwa ngokuthi "izitini ze-blade") ezisetshenziswa ezindaweni zokungena emoyeni naseziqongweni ze-arch. Lungiselela i-formwork ye-arch top kusengaphambili.

② Ukusetha: Kusisekelo esilungisiwe, phawula umugqa omaphakathi wehho kuqala, bese unquma futhi umaka imiphetho yezindonga zikahhovini kanye nezindawo zezicabha zikahhovini ngokusekelwe kupayipi elingaphansi komhlaba nendawo yokungena komoya. Maka imigqa eyisithupha eqondile yomzimba wehnu kanye nemigqa ye-arc yokugoba kokugcina ngokusekelwe kububanzi obungaphakathi obuphelele.

③ I-Masonry: Okokuqala yakha amapayipi kanye nezindawo zokungena komoya, bese ubeka izitini ezingezansi (ezidinga amatshe ahlanganisiwe anyakazayo anodaka olugcwele, awekho amalunga aqhubekayo, ukuqinisekisa ukuvala nokuvimbela ukuvuza komoya). Ukulandelana kuwukuthi: yakha izindonga eziqondile emigqeni yesisekelo esimakiwe, ishintshela emagobeni, akhiwe ngezitini ze-trapezoidal (iphutha elivumelekile ≤3mm). Njengokwezidingo zomklamo, yakha izindonga zokusekela ezixhumayo phakathi kwezindonga zomlilo zangaphakathi nezingaphandle futhi ugcwalise ngezinto zokufakelwa. Uma izindonga eziqondile zakhiwe ukuphakama okuthile, beka izitini ze-arch angle (60 ° -75 °) ukuze uqale ukwakha i-arch top. Beka i-arch formwork (ukuchezuka kwe-arc okuvumelekile ≤3mm) futhi wakhe i-arch top ngokulinganayo ukusuka ezinhlangothini zombili ukuya enkabeni. Sebenzisa izitini ze-arch (T38, T39) phezulu kwe-arch; uma kusetshenziswa izitini ezijwayelekile, qinisekisa ukuvala 贴合 nge-formwork. Lapho wakha izitini zokugcina ezingu-3-6 zendandatho ngayinye, sebenzisa izitini zokukhiya ezimise okwe-wedge (umehluko wokuqina 10-15mm) futhi uziqinise ngesando serabha. Gcina izimbobo zokubuka kanye nezimbobo zokuphakela amalahle ngaphezulu kwe-arch ngokwezidingo zomklamo.

IV. Ikhwalithi yokulawula:

b. Ukucaba: Hlola nge-straightedge yamamitha angu-2; ukungalingani okuvumelekile ≤3mm.

c. Ukubeka uphawu: Ngemva kokuqedwa kokwakhiwa kweziko, yenza ukuhlolwa kwengcindezi engalungile (-50Pa); izinga lokuvuza ≤0.5m³/h·m².

Isikhathi sokuthumela: Aug-05-2025