Uhlobo lweziko olwamukelwa kabanzi embonini yokwenza izitini namuhla iziko lomhubhe. Umqondo weziko lomhubhe wahlongozwa okokuqala futhi waqala waklanywa amaFulentshi, nakuba ungakaze wakhiwe. Ihhavini lokuqala lomhubhe elakhelwe ngokukhethekile ukukhiqizwa kwezitini ladalwa unjiniyela waseJalimane 2-incwadi ngo-1877, naye owafaka ilungelo lobunikazi kulo. Ngokusetshenziswa kabanzi kweziko lomhubhe, kwavela izinto ezintsha eziningi. Ngokusekelwe kububanzi bengqikithi yangaphakathi, zihlukaniswa ngezigaba ezincane (≤2.8 amamitha), isigaba esimaphakathi (amamitha angu-3–4), nesigaba esikhulu (≥4.6 amamitha). Ngohlobo lweziko, zifaka uhlobo lwe-micro-dome, uhlobo lophahla oluyisicaba, nohlobo olunyakazayo olumise okwendandatho. Ngendlela yokusebenza, zifaka ama-roller kilns nama-shuttle kilns. Ama-push-plate kilns. Ngokusekelwe ohlotsheni lukaphethiloli osetshenzisiwe: kukhona labo abasebenzisa amalahle njengophethiloli (okuvamile kakhulu), labo abasebenzisa igesi noma igesi yemvelo (esetshenziselwa ukudubula izitini ezinganqamuki nezitini zodonga olungenalutho, ikakhulukazi izitini ezisezingeni eliphezulu), labo abasebenzisa uwoyela osindayo noma imithombo yamandla axubile, nalabo abasebenzisa uphethiloli we-biomass, njll. Kafushane: noma iyiphi i-tunnel-type-kiln ibe i-counter-hearing esebenza ngobude bayo, i-sintering, kanye nezingxenye zokupholisa, ezinemikhiqizo ehambela ohlangothini oluphambene nokugeleza kwegesi, ihhavini lomhubhe.

Iziko lomhubhe zisetshenziswa kakhulu njengeziko lobunjiniyela obushisayo bokudubula izitini zokwakha, izitini eziphikisayo, amathayela e-ceramic, nezitsha zobumba. Eminyakeni yamuva nje, izishifu zomhubhe ziye zasetshenziselwa ukushisa ama-ejenti okuhlanza amanzi nezinto zokusetshenziswa zamabhethri e-lithium. Iziko lomhubhe zinezinhlobonhlobo zezinhlelo zokusebenza futhi ziza ngezinhlobo eziningi, ngalinye linezici zalo. Namuhla, sizogxila kuhhavini lomhubhe wezingxenye ezihlukene osetshenziselwa ukudubula izitini zokwakha.

1. Isimiso: Njengembasa yokushisa eshisayo, iziko lomhubhe ngokwemvelo lidinga umthombo wokushisa. Noma iyiphi into evuthayo engaphehla ukushisa ingasetshenziswa njengophethiloli kuhho lomhubhe (izibaseli ezihlukene zingase zibangele ukwehluka ekwakhiweni kwendawo). Uphethiloli uyasha egumbini elivuthayo ngaphakathi kuhhavini, ukhiqize igesi yokushisa ephezulu. Ngaphansi kwethonya lefeni, ukugeleza kwegesi okunezinga lokushisa eliphezulu kuhamba ngendlela ephambene nemikhiqizo exoshwayo. Ukushisa kudluliselwa ezimbotsheni zezitini emotweni yomlilo, ehamba kancane emigwaqweni ingene kuhhavini. Izitini zemoto yomlilo nazo ziyaqhubeka nokushisa. Isigaba esingaphambi kwegumbi elivuthayo yindawo yokushisa kuqala (cishe ngaphambi kokuma kwemoto yeshumi). Izikhala zezitini ziyashiswa kancane kancane futhi zifudumale endaweni yokushisa, zisuse umswakama kanye nezinto eziphilayo. Njengoba imoto yomlilo ingena endaweni ye-sintering, izitini zifinyelela izinga lokushisa eliphezulu lokudubula (850 ° C ngezitini zobumba kanye ne-1050 ° C ngezitini ze-shale) zisebenzisa ukushisa okukhishwe ekushiseni kukaphethiloli, okubhekana nezinguquko zomzimba namakhemikhali ukuze kwakhiwe isakhiwo esiminyene. Lesi sigaba siyindawo yokudubula (futhi indawo yokushisa okuphezulu) yehhani, ehlanganisa cishe izindawo ze-12 kuya kwezingu-22. Ngemva kokudlula endaweni yokudubula, izitini zithola isikhathi esithile sokufakelwa ngaphambi kokungena endaweni yokupholisa. Endaweni yokupholisa, imikhiqizo exoshiwe ihlangana nenani elikhulu lomoya obandayo ongena nge-outlet yesithando somlilo, kancane kancane uphole ngaphambi kokuphuma eziko, ngaleyo ndlela uqedele yonke inqubo yokudubula.

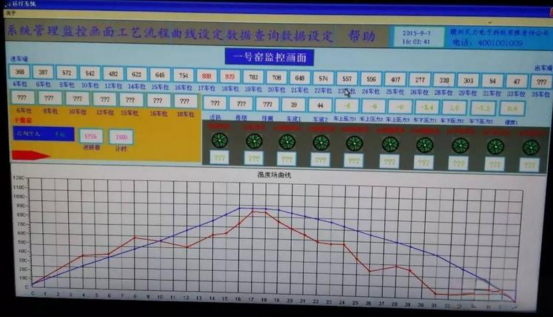

II. Ukwakhiwa: Iziko lomhubhe yimishini yobunjiniyela eshisayo. Zinebanga lokushisa elibanzi kanye nezidingo eziphakeme zesakhiwo somzimba weziko. (1) Ukulungiswa kwesisekelo: Sula imfucumfucu endaweni yokwakha futhi uqinisekise izinsiza ezintathu nendawo enezinga elilodwa. Qinisekisa ukutholakala kwamanzi, ugesi, kanye nendawo ephansi ephansi. Umthamo kufanele uhlangabezane nezidingo zokukhipha amanzi. Isisekelo kufanele sibe namandla okuthwala angu-150 kN/m². Uma uhlangabezana nezingqimba zenhlabathi ethambile, sebenzisa indlela yokufaka esikhundleni (isisekelo setshe lamatshe noma ingxube yenhlabathi ye-lime). Ngemuva kokwelashwa komsele wesisekelo, sebenzisa ukhonkolo oqinisiwe njengesisekelo somlilo. Isisekelo esiqinile siqinisekisa umthamo wokuthwala kanye nokuzinza kwehhashi. (2) Isakhiwo Seziko Izindonga zangaphakathi zehhoko ezindaweni ezishisa kakhulu kufanele zakhiwe kusetshenziswa izitini zomlilo. Izindonga zangaphandle zingase zisebenzise izitini ezijwayelekile, ngokwelashwa kokufakwa phakathi kwezitini (usebenzisa i-rock wool, i-aluminium silicate fiber blankets, njll.) ukunciphisa ukulahlekelwa ukushisa. Ubukhulu bodonga lwangaphakathi buyi-500 mm, kanti udonga lwangaphandle luyi-370 mm. Amalunga okunweba kufanele ashiywe ngokuvumelana nezidingo zokuklama. I-masonry kufanele ibe namajoyini odaka agcwele, ngezitini eziphikisayo ezibekwe emalungeni anyakazayo (amalunga odaka ≤ 3 mm) nezitini ezijwayelekile ezinodaka lwama-8-10 mm. Izinto zokuvikela i-insulation kufanele zisakazwe ngokulinganayo, zipakishwe ngokugcwele, futhi zivalwe ukuvimbela ukungena kwamanzi. (3) I-Kiln Phansi Iphansi lehholo kufanele libe indawo eyisicaba ukuze imoto yomlilo iqhubeke. Isendlalelo esimelana nomswakama kufanele sibe namandla anele okuthwala impahla kanye nezakhiwo zokushisa ezishisayo, njengoba imoto yomlilo ihamba eduze kwamathrekhi. Kuhhavini lomhubhe onobubanzi obungamamitha angu-3.6, imoto ngayinye ingalayisha cishe izitini ezimanzi ezingu-6,000. Kuhlanganisa nesisindo somzimba wemoto yokushisa, isamba somthwalo singamathani angama-20, futhi yonke ithrekhi yomlilo kufanele imelane nesisindo semoto eyodwa esingaphezu kwamathani angu-600. Ngakho-ke, ukubeka ithrekhi akumele kwenziwe budedengu. (4) Uphahla lweziko ngokuvamile lunezinhlobo ezimbili: olunama-arch kancane futhi luyisicaba. Uphahla lwe-arched luyindlela yendabuko yokwakhiwa kwamatshe, kuyilapho uphahla oluyisicaba lisebenzisa izinto ezilahlayo eziphikisayo noma izitini eziphikisayo ezingasindi ophahleni. Namuhla, abaningi basebenzisa i-silicon aluminium fiber ceiling blocks. Kungakhathalekile ukuthi iyiphi into esetshenzisiwe, kufanele iqinisekise izinga lokushisa eliphikisayo nokuvalwa, futhi izimbobo zokubuka kufanele zifakwe ezindaweni ezifanele ngokuya ngezidingo zokuklama. Imigodi yokuphakela amalahle, izimbobo zamapayipi omoya, njll. (5) Isistimu evuthayo: a. Iziko lomhubhe ezishisa izinkuni namalahle azinawo amagumbi avuthayo endaweni yokushisa ephezulu yokushisa, akhiwa kusetshenziswa izitini eziqinile, futhi anezimbobo zokuphakela uphethiloli namachweba okulahla umlotha. b. Ngokugqugquzelwa kobuchwepheshe bezitini ezivuthayo zangaphakathi, amakamelo ahlukene omlilo awasadingeki, njengoba izitini zigcina ukushisa. uma ukushisa okwanele kutholakala, uphethiloli owengeziwe ungengezwa ngezimbobo zokuphakela amalahle ophahleni lwesithando. c. Iziko ezishisa igesi yemvelo, igesi yamalahle, igesi ye-petroleum ewuketshezi, njll., zinezibasi zegesi ezinhlangothini zomlilo noma ophahleni (kuye ngokuthi hlobo luni lukaphethiloli), ezinezibasi ezisatshalaliswa ngokunengqondo nangokufana ukuze kube lula ukulawula izinga lokushisa kuhhovini. (6) Uhlelo lokungenisa umoya: a. Abalandeli: okuhlanganisa abalandeli bokunikezela, abalandeli be-exhaust, abalandeli bokukhipha umswakama, nokulinganisa abalandeli. Ukupholisa abalandeli. Ifeni ngayinye isendaweni ehlukile futhi isebenzisa umsebenzi ohlukile. Isiphephetha-moya sethula umoya egumbini elivuthayo ukuze sinikeze umoya-mpilo owanele wokuvutha, isiphephetha-moya se-exhaust sisusa amagesi aphuma kuhho ukuze kugcinwe ukucindezela okuthile okungalungile ngaphakathi kuhhovini futhi kuqinisekiswe ukugeleza kwegesi ye-flue ebushelelezi, futhi ifeni yokukhipha umswakama isusa umoya omanzi ezikhaleni zezitini ezimanzi ngaphandle kohhoko. b. Amapayipi omoya: Lawa ahlukaniswe abe imigudu yomoya kanye nemigudu yomoya. Amapayipi oflue ngokuyinhloko asusa amagesi aphumayo nomoya omanzi kuhho. Amapayipi omoya atholakala ngezinhlobo zamatshe namapayipi futhi anesibopho sokuhlinzeka komoyampilo endaweni evuthayo. c. Ama-air dampers: Afakwe emiseleni yomoya, asetshenziselwa ukulawula ukugeleza komoya kanye nomfutho weziko. Ngokulungisa usayizi wokuvula we-dampers yomoya, ukusatshalaliswa kwezinga lokushisa kanye nesikhundla somlilo ngaphakathi kwesithando somlilo singalawulwa. (7) Uhlelo lokusebenza: a. Imoto ye-Kiln: Imoto ye-kiln inendawo yokushisa ehambayo enesakhiwo esifana nomhubhe. Izikhala zezitini zihamba kancane emotweni yohhavini, zidlula endaweni yokushisa, indawo yokushisa, indawo yokushisa, indawo yokupholisa. Imoto yomlilo yenziwe ngesakhiwo sensimbi, enobukhulu obunqunywa ububanzi benetha ngaphakathi kwesithando, futhi iqinisekisa ukuvala. b. Imoto yokudlulisa: Emlonyeni womlilo, imoto yokudlulisa ihambisa imoto yomlilo. Imoto yomlilo ibe isithunyelwa endaweni yokugcina impahla, bese iyiswa endaweni yokomisa, futhi ekugcineni ihanjiswe endaweni yokucwilisa, imikhiqizo eqediwe ithuthelwe endaweni yokuthulula. c. Imishini yokudonsa ihlanganisa imishini yokudonsa ithrekhi, imishini yokuphakamisa amanzi, imishini yezinyathelo, nemishini yokudonsa umlomo. Ngamadivayisi ahlukahlukene ezindaweni ezihlukene, imoto yomlilo idonswa kumathrekhi ukuze ihambe, ifinyelela uchungechunge lwezenzo ezifana nokugcinwa kwezitini, ukomisa, ukucwilisa, ukuthulula, nokupakisha. (8) Isistimu yokulawula izinga lokushisa: Ukutholwa kwezinga lokushisa kuhilela ukufaka izinzwa zethempelesha ze-thermocouple ezindaweni ezihlukene ngaphakathi kwehhavini ukuze kuqashwe izinga lokushisa lomlilo ngesikhathi sangempela. Amasignali okushisa adluliselwa egumbini lokulawula, lapho opharetha belungisa khona umthamo wokungenisa umoya kanye nenani lomlilo ngokusekelwe kudatha yezinga lokushisa. Ukuqapha ingcindezi kuhilela ukufaka izinzwa zokucindezela kuhhoko, umsila weziko, kanye nezindawo ezibucayi ngaphakathi kwehhavini ukuze kuqashwe izinguquko zokucindezela komlilo ngesikhathi sangempela. Ngokulungisa ama-dampers omoya ohlelweni lokungenisa umoya, ukucindezela kweziko kugcinwa ezingeni elizinzile.

III. Ukusebenza: Ngemva kwendikimba eyinhloko yehhavini lomhubhe kanye nayo配套imishini isifakiwe, sekuyisikhathi sokulungiselela ukusebenza kokuthungela nokusetshenziswa okuvamile. Ukusebenzisa iziko lomhubhe akulula njengokushintsha isibani noma ukuphenyisisa iswishi; ukudubula ngempumelelo iziko lomhubhe kudinga ubuchwepheshe besayensi. Ukulawula okuqinile, ukudluliswa kokuhlangenwe nakho, nokuxhumana kuzo zonke izici eziningi kubalulekile. Izinqubo ezinemininingwane zokusebenza nezisombululo zezindaba ezingase ziphakame kuzoxoxwa ngakho kamuva. Okwamanje, ake sethule kafushane izindlela zokusebenza kanye nezinqubo zokushisa umhubhe: “Ukuhlola: Okokuqala, hlola umzimba weziko ukuze uthole noma yikuphi ukuqhekeka. Hlola ukuthi ama-joint joint seal aqinile yini. Phusha izimoto ezimbalwa ezingenalutho ezingenalutho izikhathi ezimbalwa ukuze uhlole ukuthi ithrekhi, umshini wemoto ephezulu, imoto yokudlulisa, nezinye izinto zokubamba zisebenza ngendlela evamile. qinisekisa ukuthi iyasha ngokujwayelekile. Ihora b (3) Ukubasa: Ukusebenzisa izinto zokubasa ezifana negesi yemvelo noma igesi yamalahle kulula namuhla, sizosebenzisa amalahle, izinkuni, njll Basa izinkuni namalahle, futhi kancane kancane wandise izinga lokushisa ngokulungisa ukugeleza komoya kanye nokucindezela kuze kube yilapho izikhala zezitini zifinyelela izinga lokushisa lokudubula, qala ukuphakela izimoto ezintsha kuhhavini ukusuka ngaphambili futhi uzihambise kancane kancane ubheke endaweni yokushibilika bese ufaka umshini wokushisa imoto phambili ukuqinisekisa ukuthi inqubo yokudubula iqedwa ngokuya ngejika lokushisa eliklanyelwe ④) Imisebenzi yokukhiqiza: Ukuhlelwa kwezitini: Hlela izitini emotweni yemoto ngokuhambisana nezidingo zedizayini, uqinisekise izikhala ezifanele kanye nemigudu yomoya phakathi kwezitini ukuze kube lula ukugeleza kwegesi ye-flue: Thola izinga lokushisa, ukucindezela komoya, ukuhamba komoya, kanye nokulungiswa kwekhwalithi yemoto yokushisa Izinqubo zokusebenza eziqediwe: Ngesikhathi sokusebenza kweziko lomhubhe, amazinga okushisa, izingcindezi, kanye nemingcele yegesi ye-flue endaweni yokusebenza ngayinye kufanele ihlolwe ngokuqhubekayo Indawo yokushisa kufanele ifudumale kancane (cishe 50-80% ngemitha) ukuvimbela ukuqhekeka kwezitini indawo yokupholisa ingasebenzisa idizayini yokubuyisela ukushisa kwemfucuza (yokonga amandla kanye nokunciphisa ukukhishwa kwegesi) ukuze idlulisele amandla ashisayo endaweni yokomisa izitini Ukwengeza, imoto yomlilo kufanele ithuthuke ngendlela efanayo ngokwezidingo zomklamo Ukuqinisekisa ikhwalithi yomkhiqizo, ukucindezela komoya kanye nokugeleza komoya kufanele kulungiswe ngokuya ngejika lokushisa lokuklama Londoloza umfutho ongemuhle we-20n wokucindezela. ka -10 kuya ku-50 Pa endaweni yokushisa ngaphambi kwesikhathi) ngokusekelwe kudatha yokuqapha i-Kiln exit: Lapho imoto ye-kiln ifika ekuphumeni kohhavini, izikhala zezitini ziqedile ukudubula futhi zipholile ekushiseni okufanelekile kwemoto ephethe izitini eziqediwe ingathuthelwa endaweni yokuthulula ngemishini yokuphatha, ihlolwe ukuze iqedele ukuthulula i-tunnel endaweni yokubeka izitini endaweni yokusebenzela.

Selokhu yasungulwa, ihhavini lokudubula ngezitini liye lathuthukiswa kaningi ngesakhiwo kanye nokuqanjwa kabusha kwezobuchwepheshe, kancane kancane kuthuthukisa amazinga okuvikela imvelo kanye namazinga okuzenzekelayo. Ngokuzayo, ubuhlakani, ubungane obukhulu bemvelo, kanye nokugaywa kabusha kwezinsiza kuzobusa izikhombisi-ndlela zobuchwepheshe, kuqhubekisele phambili imboni yezitini namathayela ekukhiqizeni okusezingeni eliphezulu.

Isikhathi sokuthumela: Jun-12-2025