I. Intshayelelo:

II. Ulwakhiwo:

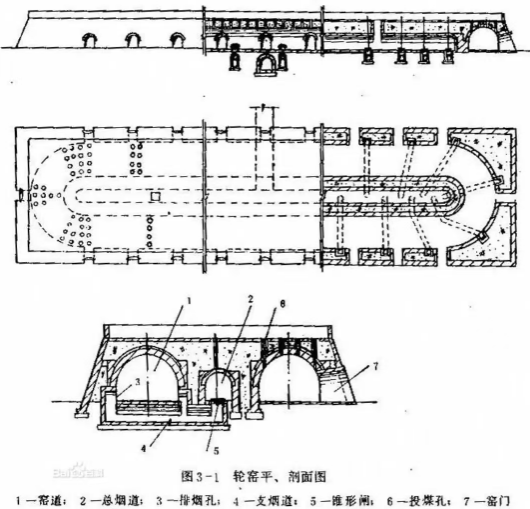

Emva kokuba izitena zifakwe kwigumbi le-oven, izithintelo zephepha kufuneka zifakwe ukuze zitywine igumbi ngalinye. Xa indawo yomlilo kufuneka ihambe, i-damper yelo gumbi ivuliwe ukudala uxinzelelo olubi ngaphakathi, olutsala idangatye elingaphambili kwigumbi kwaye litshise umqobo wephepha. Kwiimeko ezikhethekileyo, ikhonkco lomlilo lingasetyenziselwa ukukrazula umqobo wephepha wegumbi langaphambili. Ngalo lonke ixesha indawo yomlilo ihambela kwigumbi elitsha, amagumbi alandelayo angena kwinqanaba elilandelayo ngokulandelelana. Ngokuqhelekileyo, xa i-damper ivuliwe nje, igumbi lingena kwi-preheating kunye neqondo lokushisa elinyukayo; amagumbi 2-3 iingcango kude ungene kwinqanaba eliphezulu lokudubula lobushushu; amagumbi 3-4 iingcango kude ngena kwi-insulation kunye nenqanaba lokupholisa, njalo njalo. Igumbi ngalinye litshintsha ngokuqhubekayo indima yalo, lenza imveliso ye-cyclic eqhubekayo kunye nelangatye elihamba phambili. Isantya sokuhamba somlilo sichatshazelwa luxinzelelo lomoya, umthamo womoya, kunye nexabiso le-calorific yamafutha. Ukongezelela, iyahluka kunye nezitena eziluhlaza (iimitha ezi-4-6 ngeyure kwizitena ze-shale, i-3-5 yeemitha ngeyure kwizitena zodongwe). Ke ngoko, isantya sokudubula kunye nesiphumo sinokuhlengahlengiswa ngokulawula uxinzelelo lomoya kunye nevolumu ngokusebenzisa ama-dampers kunye nokulungelelanisa ukuhanjiswa kwamafutha. Ubumanzi bezitena buchaphazela ngqo isantya sokuhamba kwedangatye: ukuhla nge-1% kumxholo wokufuma kunokunyusa isantya malunga nemizuzu eyi-10. Ukutywinwa kunye nokusebenza kwe-insulation ye-kiln kukuchaphazela ngokuthe ngqo ukusetyenziswa kwamafutha kunye nokukhutshwa kwezitena ezigqityiweyo.

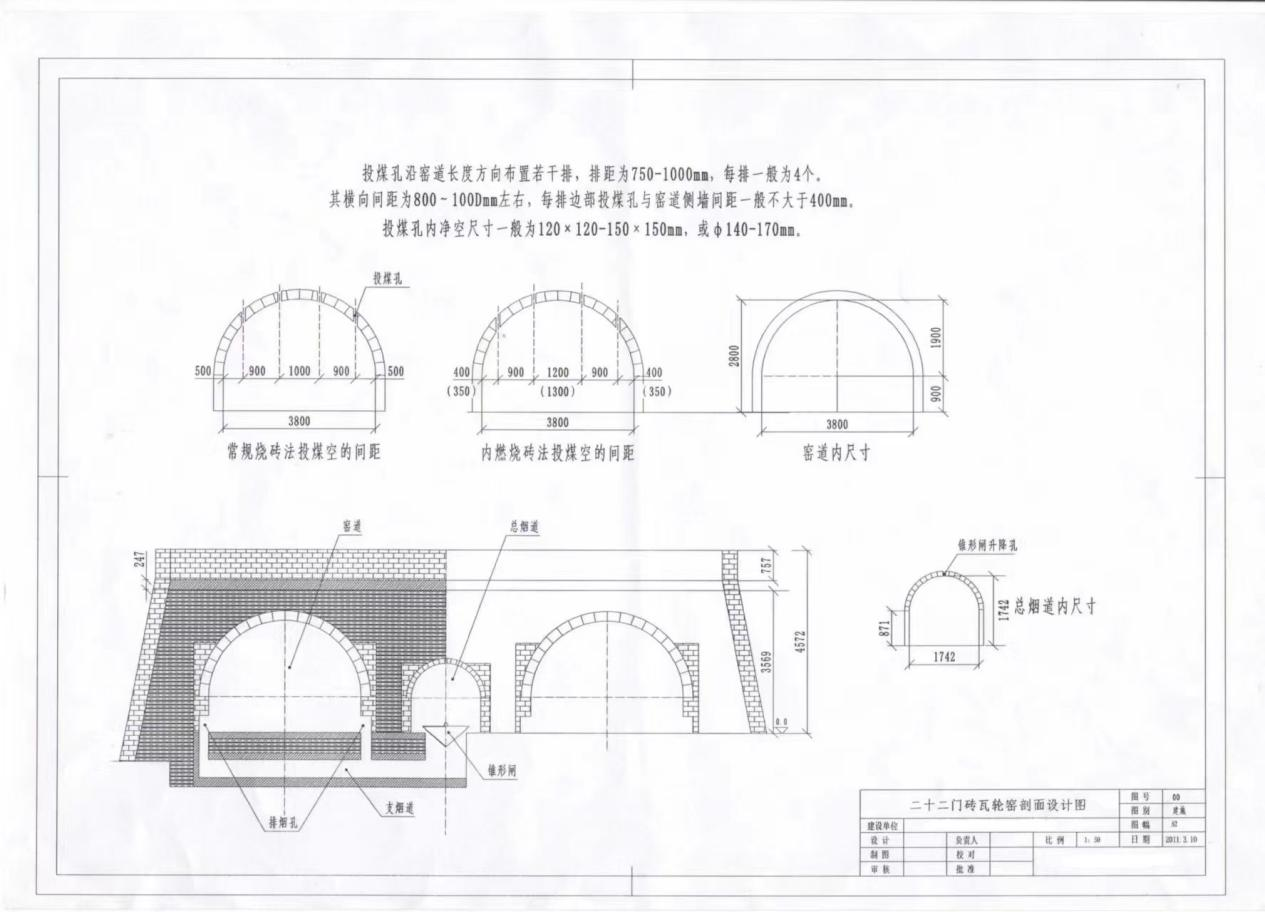

Okokuqala, ngokusekelwe kwimfuno yemveliso, misela ububanzi bangaphakathi bomnatha we-oven. Ububanzi obuhlukeneyo bangaphakathi bufuna umthamo womoya owahlukileyo. Ngokusekelwe kuxinzelelo lomoya olufunekayo kunye nomthamo, misela iinkcukacha kunye nobukhulu beendawo zokungena komoya, iiflue, iidampers, imibhobho yomoya, kunye nemibhobho yomoya engundoqo, kwaye ubale ububanzi bubonke beziko. Emva koko, misela i-fuel yokudubula izitena-amafutha ahlukeneyo afuna iindlela ezahlukeneyo zokutshisa. Kwirhasi yendalo, izikhundla zezitshisi kufuneka zigcinwe kwangaphambili; kwioli enzima (esetyenziswe emva kokufudumeza), izikhundla ze-nozzle kufuneka zigcinwe. Kwanamalahle kunye neenkuni (i-sawdust, i-rice, i-peanut shells, kunye nezinye izinto ezivuthayo ezinexabiso lobushushu), iindlela ziyahluka: amalahle atyunyuziwe, ngoko imingxuma yokutyisa amalahle ingaba yincinci; ukwenzela ukutya okulula kweenkuni, imingxuma kufuneka ibe mikhulu ngokufanelekileyo. Emva kokuyila ngokusekelwe kwidatha yecandelo ngalinye le-kiln, yakha imizobo yokwakhiwa kwe-kiln.

III. Inkqubo yokwakha:

① Uvavanyo lwejoloji: Qinisekisa ubunzulu bomaleko wamanzi aphantsi komhlaba kunye nomthamo wokuthwala umhlaba (ufuneka ≥150kPa). Kwiziseko ezithambileyo, sebenzisa iindlela zokutshintsha (isiseko sengqushu, isiseko semfumba, okanye egayiweyo 3:7 lime-soil).

② Emva konyango lwesiseko, yakha i-kiln flue kuqala kwaye usebenzise imilinganiselo yokungangeni manzi kunye nobungqina bokufuma: 抹 umaleko wodaka ongqindilili ongama-20mm, emva koko wenze unyango olungangeni manzi.

③ Isiseko se-kiln sisebenzisa i-slab ye-raft yekhonkrithi eqinisiweyo, kunye ne-φ14 imivalo yentsimbi eboshwe kwigridi ye-200mm ye-bidirectional. Ububanzi bufana neemfuno zoyilo, kwaye ubukhulu bumalunga ne-0.3-0.5 yeemitha.

④ Ukwandiswa kwamalungu: Lungiselela ijoyinti enye yokwandisa (30mm ububanzi) kuzo zonke ii-4-5 zamagumbi, azaliswe nge-asphalted hemp yokutywinwa kwamanzi.

Ukwakhiwa kweKiln Body:

① Ukulungiswa kwezinto: Emva kokuba isiseko sigqityiwe, linganisa indawo kwaye ulungiselele izinto. Izixhobo ze-Kiln: Iziphelo ezibini zehonti yakwaHoffman zisisetyhula; izitena ezikhethekileyo (izitena ze-trapezoidal, izitena ezinobumba) zisetyenziselwa ukugoba. Ukuba umzimba we-kiln wangaphakathi wakhiwe ngezitena zomlilo, udongwe lomlilo luyafuneka, ngakumbi kwizitena ze-arch (T38, T39, ezibizwa ngokuqhelekileyo ngokuthi "izitena ze-blade") ezisetyenziselwa kwii-inlets zomoya kunye ne-arch top. Lungiselela i-formwork ye-arch top kwangaphambili.

② Ukumisela: Kwisiseko esicociweyo, phawula umgca osembindini weziko kuqala, emva koko umisele kwaye uphawule imiphetho yodonga lweziko kunye neendawo zokuma kocango ngokusekwe kumbhobho ongaphantsi komhlaba kunye neendawo zokungena komoya. Phawula imigca emithandathu ethe tye kumzimba we-kiln kunye nemigca ye-arc yesiphelo sokugoba ngokusekelwe kububanzi bangaphakathi bomnatha.

③ Ukwakhiwa kweMasonry: Kuqala yakha imibhobho kunye neendawo zokungena umoya, emva koko ubeke izitena ezisezantsi (zifuna i-masonry edibeneyo edibeneyo enodaka olupheleleyo, akukho malungu aqhubekayo, ukuqinisekisa ukutywinwa kunye nokuthintela ukuvuza komoya). Ulandelelwano kukuba: yakha iindonga ezichanekileyo kunye nemigca yesiseko ephawulweyo, ukutshintshela kwii-bends, ezakhiwe ngezitena ze-trapezoidal (impazamo evumelekileyo ≤3mm). Ngokweemfuno zoyilo, yakha iindonga zenkxaso yokudibanisa phakathi kweendonga ze-oven yangaphakathi nangaphandle kwaye ugcwalise ngezinto zokugquma. Xa iindonga ezithe tye zakhiwe ukuya kumphakamo othile, beka izitena ze-arch angle (60 ° -75 °) ukuqala ukwakha i-arch top. Beka i-arch formwork (i-arc evumelekileyo ukuphambuka ≤3mm) kwaye wakhe i-arch top symmetrically ukusuka kumacala omabini ukuya kwiziko. Sebenzisa izitena ze-arch (T38, T39) kwi-arch top; ukuba izitena eziqhelekileyo zisetyenzisiwe, qinisekisa ukuba uvale 贴合 kunye nefomwork. Xa usakha izitena ezi-3-6 zokugqibela zeringi nganye, sebenzisa izitena zokutshixa ezimile okwe-wedge (umahluko wobunzima obuyi-10-15mm) kwaye uzibethelele ngokuqinileyo ngehamile yerabha. Amazibuko okuqwalaselo ogcino kunye namazibuko okutyisa amalahle kumphezulu wearch ngokweemfuno zoyilo.

IV. Ulawulo lwemeko:

b. Ukuthe tyaba: Jonga nge-2-meter straightedge; ukungalingani okuvumelekileyo ≤3mm.

c. Ukutywinwa: Emva kokuba i-kiln masonry igqityiwe, yenza uvavanyo olubi loxinzelelo (-50Pa); izinga lokuvuza ≤0.5m³/h·m².

Ixesha lokuposa: Aug-05-2025