Olona hlobo lweziko elamkelwa ngokubanzi kwishishini lokwenza izitena namhlanje liziko letonela. Ingcinga ye-tonnel kiln yacetywa kuqala kwaye yaqala ukuyilwa ngamaFrentshi, nangona ingazange yakhiwe. Itoneli yokuqala yetoneli eyenzelwe ngokukodwa ukuveliswa kwezitena yenziwa yinjineli yaseJamani i-2-incwadi ngo-1877, nayo yafaka i-patent yayo. Ngokwamkelwa okubanzi kweetoneli zetonela, izinto ezintsha ezininzi ziye zavela. Ngokusekelwe kububanzi bangaphakathi bomnatha, bahlulwe kwiindawo ezincinci (≤2.8 imitha), i-medium-section (3-4 imitha), kunye necandelo elikhulu (≥4.6 imitha). Ngohlobo lwe-kiln, zibandakanya uhlobo lwe-micro-dome, uhlobo lwesilingi esicaba, kunye nohlobo oluhambayo olunemisesane. Ngendlela yokusebenza, zibandakanya ii-roller kilns kunye ne-shuttle kilns. Iikonti zeplate zokutyhala. Ngokusekelwe kuhlobo lwamafutha asetyenziswayo: kukho abo basebenzisa amalahle njengamafutha (eyona ixhaphakileyo), abo basebenzisa igesi okanye igesi yendalo (esetyenziselwa ukudubula izitena ezingezizo kunye nezitena zodonga olucacileyo, ngokukodwa izitena eziphezulu), abo basebenzisa ioli enzima okanye imithombo yamandla exutywe, kunye nabasebenzisa i-biomass fuel, njl. i-sintering, kunye namacandelo okupholisa, kunye neemveliso ezihamba kwicala elichasene nokuhamba kwegesi, i-tonnel kiln.

Iikhilni zetonela zisetyenziswa ngokubanzi njengeento zokutshiza zobunjineli bobushushu bokudubula izitena zokwakha, izitena ezilahlayo, iithayile zeseramikhi, kunye neeseramikhi. Kwiminyaka yakutshanje, ii-tonnel kilns ziye zasetyenziselwa ukutshisa ii-arhente zokucoca amanzi kunye nezinto ezikrwada kwiibhetri ze-lithium. Iikhilni zetonela zinoluhlu olubanzi lwezicelo kwaye ziza kwiindidi ezininzi, nganye ineempawu zayo. Namhlanje, siza kugxila kwi-tunnel ye-tunnel kiln esetyenziselwa ukudubula izitena zokwakha.

1. Umgaqo: Njengeziko elitshisayo, iziko letonela ngokwendalo lifuna umthombo wobushushu. Nayiphi na into enokutsha enokuthi ivelise ubushushu inokusetyenziswa njengamafutha kwi-tunnel kiln (amafutha ahlukeneyo angabangela ukuhluka kulwakhiwo lwendawo). I-fuel iyatshisa kwigumbi lokutshisa ngaphakathi kwe-onti, ivelisa igesi ephezulu yokushisa. Ngaphantsi kweempembelelo ze-fan, ukuhamba kwegesi ephezulu yokushisa ihamba ngendlela echaseneyo neemveliso ezichithwayo. Ubushushu budluliselwa kwizitena ezivaliweyo kwimoto yomlilo, ehamba ngokucothayo ecaleni kwemizila ukuya kwiziko. Izitena zemoto ye-oven nazo ziyaqhubeka nokufudumala. Icandelo eliphambi kwegumbi lokutsha liyindawo yokufudumala (malunga nangaphambi kokuba indawo yemoto yeshumi). Izitena ezivaliweyo zifudumeza ngokuthe ngcembe kwaye zifudumale kwindawo yokufudumeza, zisusa umswakama kunye nezinto eziphilayo. Njengoko imoto ye-kiln ingena kwindawo ye-sintering, izitena zifikelela kwiqondo lokushisa eliphezulu lokudubula (850 ° C kwizitena zodongwe kunye ne-1050 ° C kwizitena ze-shale) usebenzisa ubushushu obukhutshwe ekutshisweni kwamafutha, ukuguqulwa komzimba kunye neekhemikhali ukwenza isakhiwo esixineneyo. Eli candelo liyindawo yokudubula (kwakhona yindawo yobushushu obuphezulu) ye-onti, eqala malunga neendawo ze-12 ukuya kwe-22. Emva kokudlula kwindawo yokudubula, izitena zifumana ixesha elithile lokugquma ngaphambi kokungena kwindawo yokupholisa. Kwindawo yokupholisa, iimveliso ezigxothiweyo zidibana nomoya omkhulu obandayo ongena kwi-oven outlet, ngokuthe ngcembe upholisa ngaphambi kokuba uphume kwi-oven, ngaloo ndlela ugqibezela yonke inkqubo yokudubula.

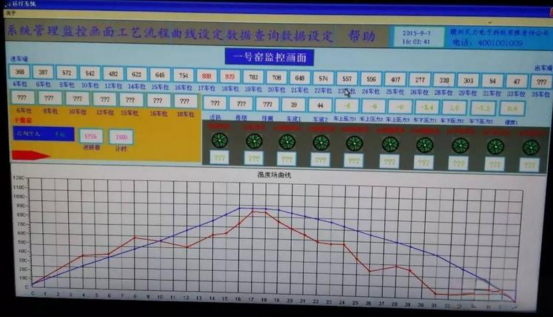

II. Ulwakhiwo: Izitofu zetonela zizitofu zobunjineli ezishushu. Zinoluhlu olubanzi lobushushu kunye neemfuno eziphezulu zesakhiwo kumzimba we-oven. (1) Ukulungiswa kwesiseko: Sula inkunkuma kwindawo yokwakha kwaye uqinisekise izinto ezintathu eziluncedo kunye nomgangatho omnye. Qinisekisa unikezelo lwamanzi, umbane, kunye nomphezulu womhlaba othe tyaba. I-slope kufuneka ihlangabezane neemfuno zokuhambisa amanzi. Isiseko kufuneka sibe nomthamo wokuthwala we-150 kN/m². Ukuba udibana neengqimba zomhlaba othambileyo, sebenzisa indlela yokubuyisela (isiseko sobume bamatye okanye umxube odityanisiweyo womhlaba wekalika). Emva konyango lwesiseko somsele, sebenzisa ikhonkrithi eyomeleziweyo njengesiseko seziko. Isiseko esomeleleyo siqinisekisa ukuthwala umthamo kunye nokuzinza kwe-kiln. (2) Ulwakhiwo lweziko Iindonga zangaphakathi zeziko kwiizowuni zobushushu obuphezulu kufuneka zakhiwe kusetyenziswa izitena zomlilo. Iindonga zangaphandle zingasebenzisa izitena eziqhelekileyo, kunye nonyango lokugquma phakathi kwezitena (usebenzisa uboya belitye, iingubo ze-aluminium silicate fiber, njl. njl.) ukunciphisa ilahleko yobushushu. Ubukhulu bodonga lwangaphakathi buyi-500 mm, kwaye udonga lwangaphandle luyi-370 mm. Amalungu okwandisa kufuneka ashiywe ngokweemfuno zoyilo. I-masonry kufuneka ibe neengqungquthela ezigcweleyo zodaka, kunye nezitena eziphikisayo ezibekwe kwiindawo ezidibeneyo (i-mortar joints ≤ 3 mm) kunye nezitena eziqhelekileyo ezinodaka lwe-8-10 mm. Izixhobo ze-insulation kufuneka zihanjiswe ngokulinganayo, zipakishwe ngokupheleleyo, kwaye zitywinwe ukukhusela ukungena kwamanzi. (3) I-Kiln Bottom Umzantsi we-onti kufuneka ube yindawo ethe tyaba ukuze inqwelo ye-onti iqhubele phambili. Umaleko wokumelana nokufuma kufuneka ube nomthamo owaneleyo wokuthwala umthwalo kunye neempawu zokugquma i-thermal, njengoko imoto ye-kiln ihamba ecaleni kwendlela. Kwihonti yetonela enobubanzi obunqamlezileyo obuziimitha ezi-3.6, imoto nganye inokulayisha malunga nama-6,000 ezitena ezimanzi. Kubandakanya ubunzima bemoto ye-oven, umthwalo uphelele ujikeleze iitoni ezingama-20, kwaye yonke ithrekhi yesibane kufuneka imelane nobunzima bemoto obungaphezulu kweetoni ezingama-600. Ngoko ke, ukubeka umzila akufuneki kwenziwe ngokungakhathali. (4) Uphahla lweziko ngokuqhelekileyo luba neendidi ezimbini: i-arched kancinane kunye nesicaba. Uphahla lwe-arched luyindlela yendabuko yokwakhiwa, ngelixa uphahla olusicaba lusebenzisa izinto ezilahlayo ezilahlayo okanye izitena ezikhanyelayo ezilula kwisilingi. Namhlanje, abaninzi basebenzisa iibhloko zesilingi ze-silicon aluminiyam. Nokuba yeyiphi na into esetyenzisiweyo, kufuneka iqinisekise ubushushu obuchasayo kunye nokutywinwa, kwaye imingxuma yokujonga kufuneka ifakwe kwiindawo ezifanelekileyo ngokweemfuno zoyilo. Imingxuma yokutyisa amalahle, imingxuma yomoya, njl njl. (5) Inkqubo yokutsha: a. Izitofu zetonela ezitshisa iinkuni kunye namalahle azinawo amagumbi okutsha kwindawo yobushushu obuphezulu beziko, ezakhiwe kusetyenziswa izitena eziqhankqalazayo, kwaye zinamazibuko okutyisa amafutha kunye namazibuko okulahla uthuthu. b. Ngokukhuthazwa kweteknoloji yezitena zokutsha zangaphakathi, amagumbi okutsha ahlukeneyo awasadingeki, njengoko izitena zigcina ukushisa. ukuba akukho bushushu obaneleyo, isibaso esongezelelweyo singongezwa ngemingxuma yokutyisa amalahle kuphahla lweziko. c. Iziko ezitshisa irhasi yendalo, irhasi yamalahle, igesi yepetroleum engamanzi, njl.njl., zinezitshisi zerhasi emacaleni okanye eluphahleni (kuxhomekeke kuhlobo lwesibaso), ezinezitshisi ezisasazwa ngokufanelekileyo nangokufanayo ukuququzelela ulawulo lobushushu ngaphakathi kwiziko. (6) Inkqubo yokungenisa umoya: a. Abalandeli: kubandakanya abalandeli bokubonelela, abalandeli bombhobho, abalandeli bokususa umswakama, kunye nabalandeli bokulinganisa. Ukupholisa abalandeli. Ifeni nganye ibekwe kwindawo eyahlukileyo kwaye isebenza ngomsebenzi owahlukileyo. I-fan yokubonelela ingenisa umoya kwindawo yokutshisa ukubonelela nge-oksijini eyaneleyo yokutshisa, i-fan exhaust isusa i-flue gases kwi-oven ukuze igcine uxinzelelo oluthile olubi ngaphakathi kwe-oven kunye nokuqinisekisa ukuhamba kwegesi epholileyo, kunye ne-fan dehumidification isusa umoya omanzi kwizitena ezimanzi ngaphandle kwesithando. b. Imibhobho yomoya: Ezi zahlulwe zaba yimibhobho engumbhobho kunye nemigudu yomoya. Imibhobho yeflue isusa iigesi zombhobho kunye nomoya omanzi kwiziko. Imibhobho yomoya ifumaneka kwiindidi ze-masonry kunye nepayipi kwaye inoxanduva lokubonelela nge-oksijini kwindawo yokutshisa. c. Izidambisi zomoya: Zifakwe kwimibhobho yomoya, zisetyenziselwa ukulawula ukuhamba komoya kunye noxinzelelo lwe-kiln. Ngokulungelelanisa ubungakanani bokuvula i-dampers yomoya, ukuhanjiswa kweqondo lokushisa kunye nesikhundla somlilo ngaphakathi kwe-kiln kunokulawulwa. (7) Inkqubo yokusebenza: a. Imoto ye-Kiln: Imoto ye-kiln ine-onti eshukumayo ephantsi enesakhiwo esifana netonela. Izitena ezivaliweyo zihamba kancinane kwimoto ye-onti, zidlula kwindawo yokufudumeza, indawo yokutshisa, indawo yokugquma, indawo yokupholisa. Imoto ye-kiln yenziwe ngesakhiwo sensimbi, kunye nemilinganiselo enqunywe yi-net ububanzi ngaphakathi kwe-oven, kwaye iqinisekisa ukutywinwa. b. Imoto yokudlulisa: Emlonyeni we-kiln, imoto yokudlulisa ihambisa imoto ye-kiln. Imoto ye-kiln ke ithunyelwa kwindawo yokugcina, emva koko kwindawo yokomisa, kwaye ekugqibeleni ifike kwindawo yokutshisa, kunye neemveliso ezigqityiweyo zihanjiswa kwindawo yokukhulula. c. Izixhobo zokutsala zibandakanya oomatshini bokutsala umkhondo, oomatshini bokuphakamisa i-hydraulic, oomatshini bokunyathela, kunye noomatshini bokutsala umlomo we-kiln. Ngezixhobo ezahlukeneyo kwiindawo ezahlukeneyo, imoto ye-oven itsalwa ecaleni kwendlela ukuze ihambe, ifezekisa uthotho lwezenzo ezinje ngokugcinwa kwezitena, ukomisa, ukuntywila, ukothula, kunye nokupakishwa. (8) Inkqubo yokulawula ubushushu: Ukufumanisa ubushushu kubandakanya ukufaka i-thermocouple sensors zeqondo lokushisa kwiindawo ezahlukeneyo ngaphakathi kwe-kiln ukujonga ubushushu be-kiln ngexesha langempela. Iimpawu zeqondo lokushisa zithunyelwa kwigumbi lokulawula, apho abaqhubi balungisa umthamo wokungenisa umoya kunye nexabiso lokutsha ngokusekelwe kwidatha yeqondo lokushisa. Ukujongwa koxinzelelo kubandakanya ukufaka i-sensor sensors kwintloko ye-kiln, umsila we-kiln, kunye neendawo ezibalulekileyo ngaphakathi kwe-oven ukujonga utshintsho kwi-kiln pressure ngexesha langempela. Ngokulungelelanisa ama-dampers omoya kwi-ventilation system, uxinzelelo lwe-kiln lugcinwa kwinqanaba elizinzile.

III. Ukusebenza: Emva komzimba oyintloko we-tunnel kiln kunye nayo配套izixhobo zifakiwe, lixesha lokulungiselela umsebenzi wokutshisa kunye nokusetyenziswa okuqhelekileyo. Ukusebenzisa i-tonnel kiln akulula njengokutshintsha ibhalbhu yesibane okanye ukupeyinta iswitshi; ukudubula ngempumelelo iziko letonela kufuna ubungcali benzululwazi. Ulawulo olungqongqo, ukuhanjiswa kwamava, kunye nolungelelwaniso kwimiba emininzi zonke zibalulekile. Iinkqubo zokusebenza ezineenkcukacha kunye nezisombululo zemiba enokuthi ivele ziya kuxoxwa kamva. Okwangoku, makhe sazise ngokufutshane iindlela zokusebenza kunye neenkqubo zokutshisa itonela: "Ukuhlola: Okokuqala, jonga umzimba we-oven ukuba akukho naziphi na iintanda. Khangela ukuba i-joint joint seal iqinile. Tshayela iimoto ezimbalwa ezingenanto ezingenanto malunga namaxesha ambalwa ukujonga ukuba umzila, umatshini wemoto ephezulu, imoto yokudlulisa, kunye nezinye izixhobo zokuphatha zisebenza njengesiqhelo. qinisekisa ukuba iyatshisa ngokuqhelekileyo indlela yokumisa i-Kiln iyahluka ngokuxhomekeke kuhlobo lwesibaso esisetyenzisiweyo. iyure b. Inqanaba lobushushu eliphakathi (200-600 ° C): Izinga lobushushu lokunyuka kwe-10-15 ° C ngeyure, kwaye ubhake iintsuku ezimbini zeqondo lokushisa eliphezulu (i-600 ° C nangaphezulu): ukwandisa izinga lokushisa kwe-20 ° C ngeyure de ubushushu bokudubula bufikeleleke ngexesha lokunyuka komzimba Ukufuma Lungisa iinkuni kunye namalahle, kwaye ngokuthe ngcembe wandise ubushushu ngokulungisa ukuhamba komoya kunye noxinzelelo de izitena ezivaliweyo zifikelele kwiqondo lokushisa lokudubula, qalisa ukutyisa iimoto ezintsha kwi-oven ukusuka ngaphambili kwaye uqhubele phambili ukuya kwindawo yokutshisa ukuqinisekisa ukuba inkqubo yokudubula igqityiwe ngokuhambelana nejiko lobushushu eliyilelweyo ④) Imisebenzi yokuvelisa: Lungiselela izitena kwimoto yomlilo ngokweemfuno zoyilo, uqinisekisa izikhewu ezifanelekileyo kunye nemijelo yomoya phakathi kwezitena ukuququzelela ukuhamba kwegesi egudileyo Iinkqubo zokuSebenza ezigqityiweyo: Ngexesha lokusebenza kwe-tunnel, amaqondo obushushu, uxinzelelo, kunye neeparamitha zegesi ye-flue kwindawo nganye yokusebenza kufuneka ihlale ibekwe esweni Indawo yokutshisa i-preheating kufuneka ifudunyezwe ngokucothayo (malunga ne-50-80% ngemitha) ukuthintela ukuqhekeka kwezitena indawo yokupholisa inokusebenzisa uyilo lokubuyisela ubushushu benkunkuma (ukugcina amandla kunye nokunciphisa ukukhutshwa kwegesi) ukuhambisa amandla ashushu kwindawo yokomisa izitena Ukongeza, imoto ye-oven kufuneka iqhubele phambili ngokulinganayo ngokweemfuno zoyilo Ukuqinisekisa umgangatho wemveliso, uxinzelelo lomoya kunye nokuhamba komoya kufuneka kuhlengahlengiswe ngokusekwe kuyilo lweqondo lobushushu kwijika le-10 loxinzelelo oluzinzileyo. of -10 ukuya -50 Pa kwindawo preheating) ngokusekwe esweni data Kiln yokuphuma: Xa inqwelo eziko ifikelela yokuphuma kwitonela, izitena ezingenanto zigqityiwe ukudubula kwaye zipholile kwiqondo lobushushu elifanelekileyo Imoto eziko ethwele izitena ezigqityiweyo emva koko zithuthelwe kwindawo yokothula nge-kiln yokuphuma, ihlolwe ukugqitywa kwe-tunnel ye-tunnel kwindawo yokubeka izitena kwindawo yokusebenzela.

Ukususela ekuvelisweni kwayo, i-tonnel yokutshisa izitena iye yafumana ukulungiswa kwezinto ezininzi kunye nokwenziwa kwezinto ezintsha zobuchwepheshe, ngokuthe ngcembe iphucula imigangatho yokukhusela indalo kunye namanqanaba okuzenzekelayo. Kwixesha elizayo, ubukrelekrele, ubuhlobo obungaphezulu kokusingqongileyo, kunye nokuphinda kusetyenziswe izixhobo kuya kulawula izalathiso zetekhnoloji, ukuqhuba ishishini lezitena kunye neethayile ukuya kwimveliso ephezulu.

Ixesha lokuposa: Jun-12-2025