I. Gabatarwa:

II. Tsarin:

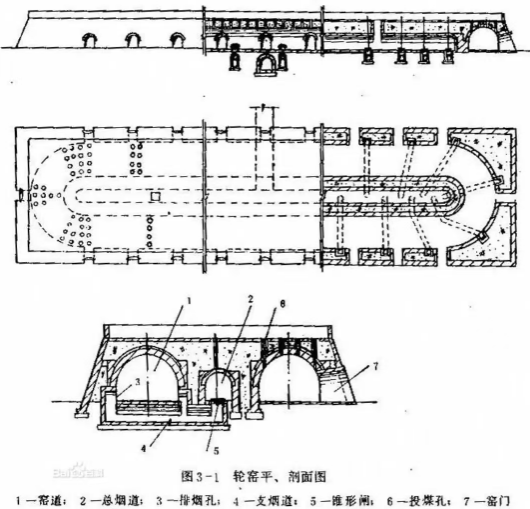

Bayan an tara tubali a cikin ɗakin murhu, dole ne a liƙa shingen takarda don rufe ɗakin ɗaya. Lokacin da matsayi na wuta yana buƙatar motsawa, an buɗe damper na wannan ɗakin don haifar da mummunan matsa lamba a ciki, wanda ya jawo gaban harshen wuta a cikin ɗakin kuma ya ƙone shingen takarda. A lokuta na musamman, ana iya amfani da ƙugiya ta wuta don yaga shingen takarda na ɗakin da ya gabata. Duk lokacin da yanayin wuta ya motsa zuwa sabon ɗakin, ɗakunan da ke gaba suna shiga mataki na gaba a jere. Yawancin lokaci, lokacin da aka buɗe damper kawai, ɗakin yana shiga cikin preheating da yanayin zafi; ɗakunan 2-3 kofofin nesa sun shiga matakin harbi mai zafi; ɗakunan 3-4 kofofi nesa suna shiga matakin rufewa da sanyaya, da sauransu. Kowane ɗakin daki yana ci gaba da canza matsayinsa, yana samar da ci gaba da samar da cyclic tare da gaban harshen wuta mai motsi. Gudun tafiye-tafiyen harshen wuta yana shafar matsa lamba na iska, ƙarar iska, da ƙimar kuzarin mai. Bugu da ƙari, ya bambanta da albarkatun bulo (mita 4-6 a kowace awa don tubalin shale, mita 3-5 a kowace awa don tubalin yumbu). Sabili da haka, ana iya daidaita saurin harbe-harbe da fitarwa ta hanyar sarrafa karfin iska da ƙarar ta hanyar dampers da daidaita samar da man fetur. Abubuwan da ke cikin bulo suma yana shafar saurin tafiya na harshen wuta kai tsaye: raguwar 1% cikin abun ciki na danshi na iya ƙara saurin da kusan mintuna 10. Ayyukan rufewa da rufewa na kiln kai tsaye suna shafar amfani da man fetur da gama aikin bulo.

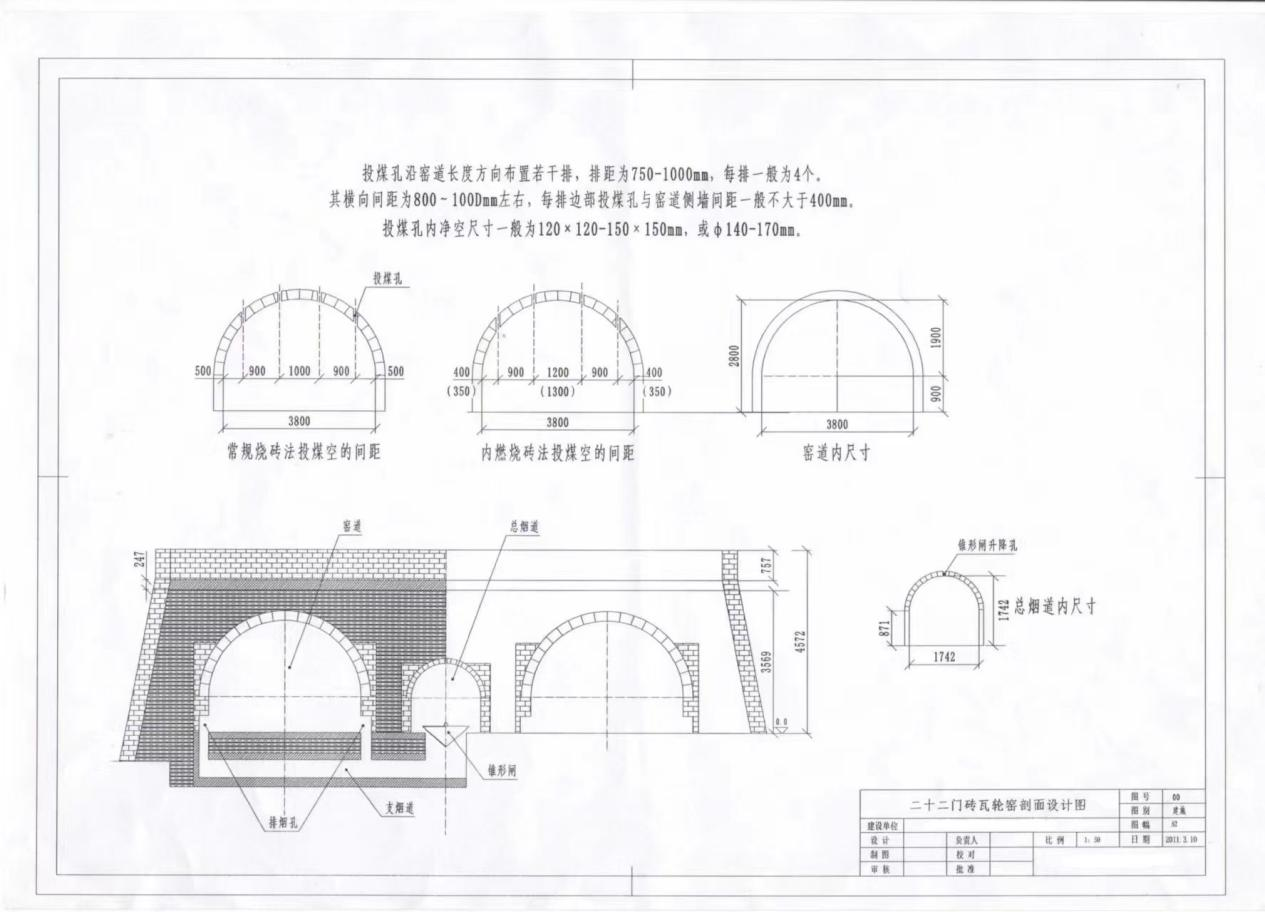

Na farko, dangane da abin da ake buƙata na fitarwa, ƙayyade net na ciki nisa na kiln. Daban-daban nisa na ciki suna buƙatar nau'ikan iska daban-daban. Dangane da matsa lamba da ƙarar da ake buƙata, ƙididdige ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun magudanar iska na murhu, hayaƙi, dampers, bututun iska, da manyan magudanan iska, da ƙididdige jimlar faɗin kiln. Sa'an nan kuma, ƙayyade man fetur don yin amfani da bulo - nau'in man fetur daban-daban yana buƙatar hanyoyi daban-daban na konewa. Don iskar gas, matsayi na masu ƙonewa dole ne a riga an ajiye su; don mai mai nauyi (amfani da bayan dumama), dole ne a adana wuraren bututun ƙarfe. Ko da gawayi da itace (sawdust, shinkafa shinkafa, bawon gyada, da sauran abubuwa masu ƙonewa tare da darajar zafi), hanyoyin sun bambanta: ana murƙushe kwal, don haka ramukan ciyar da gawayi na iya zama karami; don ciyar da itace mai sauƙi, ramukan ya kamata ya fi girma daidai. Bayan zayyana dangane da bayanan kowane ɓangaren kiln, gina zane-zanen ginin kiln.

III. Tsarin Gina:

① Binciken Geological: Tabbatar da zurfin ruwan ƙasa da ƙarfin ɗaukar ƙasa (ana buƙatar zama ≥150kPa). Don tushe mai laushi, yi amfani da hanyoyin maye gurbin (tushen tarkace, tushen tudu, ko ƙaƙƙarfan 3: 7 lemun tsami-ƙasa).

② Bayan jiyya na tushe, fara fara yin bututun kiln sannan a yi amfani da matakan hana ruwa da danshi: 抹 20mm turmi mai kauri mai kauri, sannan a yi maganin hana ruwa.

③ Tushen kiln yana amfani da ƙwanƙwasa ƙwanƙwasa ƙwanƙwasa, tare da sandunan ƙarfe φ14 da aka ɗaure a cikin grid bidirectional 200mm. Nisa shine gwargwadon buƙatun ƙira, kuma kauri shine kusan mita 0.3-0.5.

④ Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) na Ƙarƙashin Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa: Shirya haɗin haɓaka guda ɗaya (30mm wide) don kowane ɗakin 4-5, cike da hemp na asphalted don rufewar ruwa.

Ginin Jikin Kilin:

① Shirye-shiryen kayan aiki: Bayan an kammala kafuwar, daidaita wurin da kuma shirya kayan. Kayan kiln: Ƙarshen biyu na kiln Hoffman suna da madauwari; Ana amfani da tubali na musamman (bulogin trapezoidal, tubali mai siffar fan) a lanƙwasa. Idan an gina jikin kiln na ciki da tubalin wuta, ana buƙatar yumbu na wuta, musamman don tubalin baka (T38, T39, wanda aka fi sani da "bulo na ruwa") da ake amfani da su a mashigin iska da saman saman. Shirya formwork don saman baka a gaba.

② Saita: A kan harsashin da aka yi wa magani, fara fara alama a tsakiyar kiln, sa'an nan kuma ƙayyade kuma yi alama a gefuna bangon kiln da wuraren ƙofofin kiln dangane da bututun ƙasa da wuraren shigar iska. Alama madaidaitan layuka shida don jikin kiln da layin baka don lanƙwasawa na ƙarshe dangane da faɗuwar ciki.

③ Masonry: Da farko a gina hayaki da mashigai na iska, sannan a shimfiɗa tubalin ƙasa (yana buƙatar mashin ɗin haɗin gwiwa tare da cikakken turmi, babu ci gaba da haɗin gwiwa, don tabbatar da rufewa da hana zubar iska). Jerin shine: gina ganuwar madaidaiciya tare da layin tushe mai alamar, canzawa zuwa bends, waɗanda aka gina tare da tubalin trapezoidal (kuskuren izini ≤3mm). Dangane da buƙatun ƙira, gina bangon goyan bayan haɗawa tsakanin bangon kiln ciki da na waje kuma cika da kayan kwalliya. Lokacin da aka gina madaidaicin ganuwar zuwa wani tsayi, a shimfiɗa tubalin kusurwa (60°-75°) don fara gina saman baka. Sanya tsarin aikin baka (wanda aka yarda da karkacewar baka ≤3mm) kuma gina saman baka a ma'ana daga bangarorin biyu zuwa tsakiya. Yi amfani da tubalin baka (T38, T39) don saman baka; idan ana amfani da tubali na yau da kullun, tabbatar da kusanci da tsarin aiki. Lokacin gina tubalin 3-6 na ƙarshe na kowane zobe, yi amfani da tubalin kulle mai siffa (banbancin kauri 10-15mm) kuma a datse su da guduma ta roba. Ajiye tashar jiragen ruwa na lura da tashoshin ciyar da kwal a saman baka kamar yadda buƙatun ƙira.

IV. Kula da inganci:

b. Flatness: Duba tare da madaidaiciyar mita 2; rashin daidaituwa ≤3mm.

c. Rufewa: Bayan kammala masonry na kiln, gudanar da gwajin gwaji mara kyau (-50Pa); Yawan zubar ≤0.5m³/h·m².

Lokacin aikawa: Agusta-05-2025