Nau'in kiln da aka fi ɗauka a cikin masana'antar yin bulo a yau shine murhun rami. Tunanin tunnel kiln an fara tsara shi kuma Faransawa ne suka tsara shi da farko, kodayake ba a taɓa gina shi ba. Injiniyan 2-littafi na Jamus ne ya ƙirƙira tukunyar rami na farko da aka kera musamman don samar da bulo a cikin 1877, wanda kuma ya ba da takardar shaidar mallaka. Tare da yaɗuwar rundunan tunnels, sabbin abubuwa da yawa sun fito. Dangane da faɗin gidan yanar gizon na ciki, an rarraba su zuwa ƙananan yanki (mita ≤2.8), matsakaici (mita 3-4), da babban sashi (≥4.6 mita). Ta nau'in kiln, sun haɗa da nau'in micro-dome, nau'in silin lebur, da nau'in motsi mai siffar zobe. Ta hanyar aiki, sun haɗa da kilns na abin nadi da na'urorin jigilar kaya. Tura-farantin kilns. Dangane da nau'in man da ake amfani da shi: akwai masu amfani da gawayi a matsayin mai (mafi na kowa), masu amfani da iskar gas ko iskar gas (an yi amfani da su don harba tubalin da ba su da ƙarfi da bulo na bangon bango, da farko don bulo mai tsayi), waɗanda ke amfani da mai mai nauyi ko tushen makamashi mai gauraya, da waɗanda ke amfani da man biomass, da sauransu. sassan, tare da samfurori da ke tafiya a kishiyar hanya zuwa kwararar iskar gas, rami ne na kiln.

Ana amfani da kiln ɗin rami ko'ina azaman kiln injiniyan zafi don harba bulo na gini, bulo mai hana ruwa, fale-falen yumbu, da yumbu. A cikin 'yan shekarun nan, an kuma yi amfani da kilns na rami don ƙone kayan aikin tsabtace ruwa da albarkatun ƙasa don batir lithium. Tunnel kilns suna da nau'ikan aikace-aikace da yawa kuma suna zuwa iri-iri, kowanne yana da halayensa. A yau, za mu mai da hankali kan kaskon ramin ramin da ake amfani da shi don harba tubalin ginin.

1. Ƙa'ida: A matsayin murhu mai zafi, ɗakin ramin ramin yana buƙatar tushen zafi. Duk wani abu mai ƙonewa wanda zai iya haifar da zafi za a iya amfani da shi azaman mai don tunnel kiln (haka daban-daban na iya haifar da bambancin ginin gida). Man fetur yana ƙonewa a ɗakin konewar da ke cikin murhu, yana samar da iskar gas mai zafi. A ƙarƙashin rinjayar fan, yawan zafin jiki na iskar gas yana motsawa a cikin kishiyar hanya zuwa samfuran da aka harba. Ana canza zafi zuwa bulo na bulo a kan motar kiln, wanda ke motsawa a hankali tare da waƙoƙin zuwa cikin kiln. Haka kuma bulo-bulen da ke jikin motar kiln din na ci gaba da yin zafi. Sashin da ke gaban ɗakin konewa shine yankin preheating (kimanin kafin matsayi na goma). Wuraren bulo suna mai zafi a hankali kuma suna dumama a cikin yankin preheating, cire danshi da kwayoyin halitta. Yayin da motar kiln ta shiga yankin sintering, tubalin sun kai matsakaicin zafin wuta (850 ° C don tubalin yumbu da 1050 ° C don tubalin shale) ta amfani da zafin da aka fitar daga konewar man fetur, suna fuskantar canje-canje na jiki da na sinadarai don samar da tsari mai yawa. Wannan sashe shine yanki na harbe-harbe (shima yankin zafi mai zafi) na kiln, wanda ya kai kusan matsayi na 12 zuwa 22. Bayan wucewa ta yankin harbe-harbe, tubalin suna ɗaukar wani lokaci na rufewa kafin shiga yankin sanyaya. A cikin yankin sanyaya, samfuran da aka kora suna haɗuwa da iskar sanyi mai yawa da ke shiga ta hanyar murhu, sannu a hankali suna kwantar da hankali kafin su fita daga cikin kiln, don haka kammala aikin harbi duka.

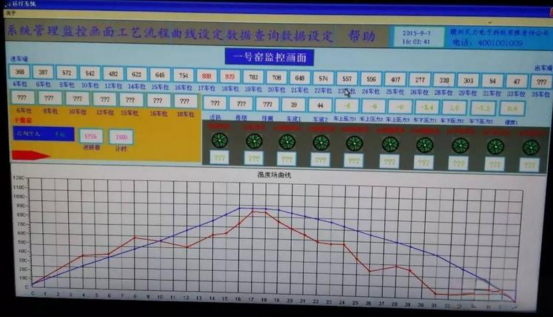

II. Gina: Ramin kiln ɗin injiniyoyin zafi ne. Suna da kewayon zafin jiki mai faɗi da manyan buƙatun tsarin don jikin kiln. (1) Shirye-shiryen Gidauniyar: Tsabtace tarkace daga wurin ginin kuma tabbatar da abubuwan amfani uku da saman matakin daya. Tabbatar da samar da ruwa, wutar lantarki, da madaidaicin saman ƙasa. Dole gangaren ta cika buƙatun magudanar ruwa. Tushen ya kamata ya kasance yana da ƙarfin ɗaukar nauyi na 150 kN/m². Idan an haɗu da shimfidar ƙasa mai laushi, yi amfani da hanyar maye gurbin (tushen ginin dutse ko cakuda ƙasa-ƙasa). Bayan ginshiƙan maɓalli na tushe, yi amfani da siminti mai ƙarfi azaman tushe na kiln. Tushen tushe mai ƙarfi yana tabbatar da ƙarfin ɗauka da kwanciyar hankali. (2) Tsarin Kiln Ya kamata a gina bangon ciki na kiln a wurare masu zafi da zafi ta amfani da tubalin wuta. Ganuwar waje na iya amfani da tubali na yau da kullun, tare da jiyya tsakanin tubalin (ta amfani da ulun dutse, bargo na fiber silicate na aluminum, da sauransu) don rage asarar zafi. Kaurin bangon ciki shine mm 500, kaurin bangon waje kuma shine 370 mm. Ya kamata a bar haɗin haɓakawa bisa ga buƙatun ƙira. Masonry ya kamata ya kasance da cikakkun kayan aikin turmi, tare da tubalin tubali da aka shimfiɗa a cikin mahaɗar daɗaɗɗen (turmi ≤ 3 mm) da tubali na yau da kullum tare da turmi na 8-10 mm. Ya kamata a rarraba kayan rufewa daidai gwargwado, cike da cika, kuma a rufe su don hana shigar ruwa. (3) Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙarƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙaƙa don Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙashin Ƙa ) ya kamata ya yi ya zama fili don motar kiln ta ci gaba. Dole ne Layer da ke jure danshi dole ne ya sami isassun ƙarfin ɗaukar kaya da kaddarorin rufewa, yayin da motar kiln ke tafiya tare da waƙoƙi. A cikin kwandon rami mai faɗin yanki mai faɗin mita 3.6, kowace mota na iya ɗaukar bulo mai jika kusan 6,000. Ciki har da nauyin nauyin motar kiln, jimillar lodi ya kai tan 20, kuma gaba dayan titin kiln dole ne ya yi tsayin daka na nauyin mota guda daya sama da tan 600. Don haka, bai kamata a yi sakaci ba. (4) Rufin kiln yawanci yana da nau'ikan iri biyu: ɗan lebur da lebur. Rufin da aka ɗora hanya ce ta gargajiya, yayin da lebur ɗin ke amfani da kayan da za a iya cirewa ko bulo mai nauyi don rufin. A zamanin yau, mutane da yawa suna amfani da tubalan rufin siliki na aluminum fiber. Ko da kuwa kayan da aka yi amfani da su, dole ne ya tabbatar da zafin jiki da rufewa, kuma dole ne a shigar da ramukan kallo a wurare masu dacewa bisa ga bukatun ƙira. Ramin ciyar da kwal, ramukan bututun iska, da sauransu. (5) Tsarin konewa: a. Ramin dakunan da ke kona itace da kwal ba su da dakunan konawa a yankin da ke da zafi mai zafi na kaskon, waɗanda ake gina su ta amfani da bulo mai hana ruwa gudu, kuma suna da tashoshin ciyar da mai da tashoshin fitar da toka. b. Tare da haɓaka fasahar bulo mai ƙonewa na ciki, ba a buƙatar ɗakunan konewa daban, saboda tubalin yana riƙe da zafi. idan babu isasshen zafi, za a iya ƙara ƙarin man fetur ta hanyar ramukan ciyar da gawayi a kan rufin kiln. c. Kilns na kona iskar gas, iskar gas, iskar gas mai ruwa, da dai sauransu, suna da masu ƙona iskar gas a ɓangarorin kiln ko rufin (ya danganta da nau'in mai), tare da masu ƙonewa da aka rarraba bisa ga gaskiya da daidaito don sauƙaƙe sarrafa zafin jiki a cikin kiln. (6) Tsarin iska: a. Magoya baya: gami da masu ba da kayayyaki, masu shaye-shaye, magoya bayan humidation, da daidaita magoya baya. Masoya masu sanyaya zuciya. Kowane fan yana samuwa a cikin matsayi daban-daban kuma yana aiki daban-daban. Mai ba da wutar lantarki yana gabatar da iska a cikin ɗakin konewa don samar da isassun iskar oxygen don konewa, mai shayarwa yana cire iskar hayaki daga cikin kiln don kula da wani mummunan matsa lamba a cikin kiln da kuma tabbatar da iskar gas mai laushi mai laushi, kuma fan na dehumidification yana cire iska mai laushi daga rigar bulo a waje da kiln. b. Matsalolin iska: An raba waɗannan zuwa bututun hayaƙi da kuma iskar iska. Tushen bututun ruwa da farko suna fitar da iskar hayaki da rigar iska daga tanda. Ana samun bututun iska a cikin masonry da nau'ikan bututu kuma suna da alhakin samar da iskar oxygen zuwa yankin konewa. c. Dampers na iska: An sanya su a kan iskar iska, ana amfani da su don daidaita yanayin iska da matsa lamba. Ta hanyar daidaita girman buɗewar dampers na iska, ana iya sarrafa rarraba zazzabi da matsayi na harshen wuta a cikin kiln. (7) Tsarin aiki: a. Motar kiln: Motar kiln tana da gindin kiln mai motsi tare da tsari mai kama da rami. Abubuwan bulo suna motsawa a hankali akan motar kiln, suna wucewa ta yankin preheating, yankin sintering, yankin insulation, yankin sanyaya. Motar kiln ɗin an yi ta ne da tsarin ƙarfe, tare da ƙayyadaddun ƙima da faɗin gidan yanar gizon da ke cikin kiln, kuma yana tabbatar da hatimi. b. Motar canja wuri: A bakin kiln, motar canja wuri ta motsa motar kiln. Daga nan sai a aika da motar kiln zuwa yankin da ake ajiyewa, sannan a tura wurin da ake bushewa, daga karshe kuma a kai ga yankin da ake hadawa, tare da kai kayayyakin da aka gama zuwa wurin sauke kaya. c. Kayan aikin jan hankali sun haɗa da injunan juzu'i, injunan ɗaga ruwa na ruwa, injinan mataki, da injunan juzu'i na kiln-baki. Ta hanyar na'urori daban-daban a wurare daban-daban, ana jan motar kiln tare da waƙoƙi don motsawa, cimma jerin ayyuka kamar ajiyar bulo, bushewa, ƙwanƙwasa, saukewa, da marufi. (8) Tsarin kula da yanayin zafi: Gano yanayin zafin jiki ya haɗa da shigar da na'urori masu auna zafin jiki na thermocouple a wurare daban-daban a cikin kiln don saka idanu zafin kiln a cikin ainihin lokaci. Ana watsa siginar zafin jiki zuwa ɗakin sarrafawa, inda masu aiki ke daidaita ƙarar yawan iska da ƙimar konewa dangane da bayanan zafin jiki. Kulawar matsin lamba ya haɗa da shigar da na'urori masu auna matsa lamba a kan kiln, wutsiya, da wurare masu mahimmanci a cikin kiln don saka idanu akan canje-canje a cikin matsa lamba a cikin ainihin lokaci. Ta hanyar daidaita dampers na iska a cikin tsarin samun iska, ana kiyaye matsa lamba na kiln a matakin kwanciyar hankali.

III. Aiki: Bayan babban jikin ramin kiln da ta配套an shigar da kayan aiki, lokaci ya yi da za a shirya don aikin kunnawa da amfani da al'ada. Yin aiki da murhun rami ba shi da sauƙi kamar canza kwan fitila ko jujjuya maɓalli; nasarar harba tankar ramin yana buƙatar ƙwarewar kimiyya. Tsananin sarrafawa, watsa gwaninta, da daidaitawa ta fannoni da yawa duk suna da mahimmanci. Cikakkun hanyoyin aiwatarwa da mafita ga al'amuran da ka iya tasowa za a tattauna daga baya. A yanzu, bari mu ɗan gabatar da hanyoyin aiki da matakai na kiln rami: "Bincike: Na farko, bincika jikin kiln don kowane fashe. Bincika idan hatimin haɓakar haɗin gwiwa yana da ƙarfi. Tura wasu motoci marasa komai a kusa da wasu lokuta don bincika ko waƙa, injin mota na sama, motar canja wuri, da sauran kayan sarrafa kayan aiki suna aiki kullum. A al'ada Bincika idan duk hanyoyin bushewar kil sun bambanta dangane da nau'in man da aka yi amfani da su. Duk da haka, makasudin ya kasance daidai: don cire danshi a hankali a cikin tsarin ginin ta hanyar bushewa, yana hana dumama mai zafi da zafi a cikin awa daya. Matsakaici-zazzabi mataki (200-600 ° C): Zazzabi ya tashi 10-15 ° C a kowace awa, da kuma gasa na tsawon kwanaki biyu c. Ignition: Yin amfani da man fetur kamar iskar gas ko iskar gas yana da sauƙi a yau, za mu yi amfani da gawayi, itace, da dai sauransu. (3) A matsayin misali, da farko fara yin katako don kunna wuta: sanya itacen wuta, kwal, da sauran abubuwa masu ƙonewa a kan keken kiln, kunna fan don haifar da wutan wuta a cikin wuta Kwal, kuma sannu a hankali ƙara yawan zafin jiki ta hanyar daidaita yanayin iska da matsa lamba har sai bulo ya kai zafin harbi, fara ciyar da sabbin motoci zuwa cikin kiln daga gaba kuma a hankali matsar da su zuwa yankin sintering a gaba don kammala kunna wutar lantarki a duk lokacin da ake kunna wutar lantarki. Tsarin zafin jiki da aka tsara. Yanayin zafi, matsa lamba, da ma'auni na iskar gas a kowane wurin aiki dole ne a ci gaba da kula da yankin preheating a hankali (kimanin 50-80% a kowace mita) don hana fashewar bulo ya kamata ya kula da yawan zafin jiki na ≤ ± 10 ° C don tabbatar da yin amfani da tubali mai zafi Rage watsi) don canja wurin makamashin thermal zuwa yankin bushewa don bushewa da bulo, dole ne a haɓaka motar kiln daidai da buƙatun ƙira, don tabbatar da ingancin samfurin, matsa lamba na iska da yanayin zafin jiki Fita: Lokacin da motar kiln ta isa wurin fitowar ramin, bulo ɗin sun gama harbe-harbe kuma sun sanyaya zuwa yanayin da ya dace sake zagayowar.

Tun da aka ƙirƙira shi, tubali-harbin tunnel kiln ya sami gyare-gyaren tsari da yawa da sabbin fasahohi, sannu a hankali yana haɓaka matakan kare muhalli da matakan sarrafa kansa. A nan gaba, hazaka, kyakkyawar abokantaka na muhalli, da sake amfani da albarkatu za su mamaye kwatancen fasaha, da tura masana'antar bulo da tayal zuwa masana'anta na ƙarshe.

Lokacin aikawa: Juni-12-2025